Every time your vehicle hits a pothole, speed bump, or rough terrain, a small but critical component prevents thousands of dollars in suspension damage. Bump stops—those often-overlooked rubber or polyurethane cushions in your suspension system—serve as the final line of defense between controlled suspension travel and catastrophic component failure. While most drivers never think about these unassuming parts, understanding how bump stops work reveals why they’re essential for both everyday driving and specialized applications like off-roading or performance driving.

Bump stops, also called jounce bumpers or suspension travel limiters, function as progressive-rate cushions that engage when your suspension reaches maximum compression. Their primary job is preventing metal-on-metal contact between suspension components and the vehicle frame, protecting expensive shock absorbers from internal damage, and maintaining ride quality even under extreme conditions. Whether you’re hauling heavy loads, navigating rough trails, or simply driving over city streets, bump stops work silently to absorb impacts that would otherwise damage your suspension system.

This guide explores the mechanical principles behind bump stops, the different types available for various applications, and why these components deserve attention during routine maintenance. We’ll examine how bump stops protect your suspension investment, when replacement becomes necessary, and how performance enthusiasts use advanced hydraulic bump stops to fine-tune suspension behavior. Understanding bump stops helps you make informed decisions about suspension maintenance and upgrades while avoiding costly repairs down the road.

What Bump Stops Are and Their Primary Function

Bump stops go by several names in the automotive world—jounce bumpers, axle snubbers, compression limiters—but they all refer to the same critical suspension component. These relatively small parts, typically made from rubber, polyurethane, or in advanced applications, hydraulic cylinders, occupy strategic positions throughout your vehicle’s suspension system. Despite their modest size, bump stops perform multiple essential functions that protect both suspension components and vehicle occupants.

The core function of a bump stop is preventing excessive suspension compression that could damage components or compromise safety. When your suspension travels through its full range of motion—whether from hitting a large bump, carrying heavy cargo, or experiencing extreme articulation off-road—the bump stop provides a cushioned barrier that prevents metal parts from crashing together. This seemingly simple role actually involves sophisticated engineering to balance protection with ride quality.

Bump stops serve six distinct protective functions in modern suspension systems. First, they prevent metal-on-metal contact between suspension arms and the vehicle frame, which could bend components or crack welds. Second, they protect shock absorbers and struts from internal bottoming, a condition where the shock’s piston slams into the end cap and causes internal damage. Third, bump stops prevent tire-to-fender contact that could damage both the tire sidewall and vehicle body. Fourth, they isolate sprung masses (the vehicle body) from unsprung masses (wheels and suspension components) under full compression conditions, preventing harsh impact transmission to the cabin. Fifth, they prevent coil bind in spring suspensions, a dangerous condition where coil springs compress completely and can no longer absorb energy. Finally, bump stops act as progressive-rate supplemental springs, adding stiffness gradually rather than abruptly stopping suspension movement.

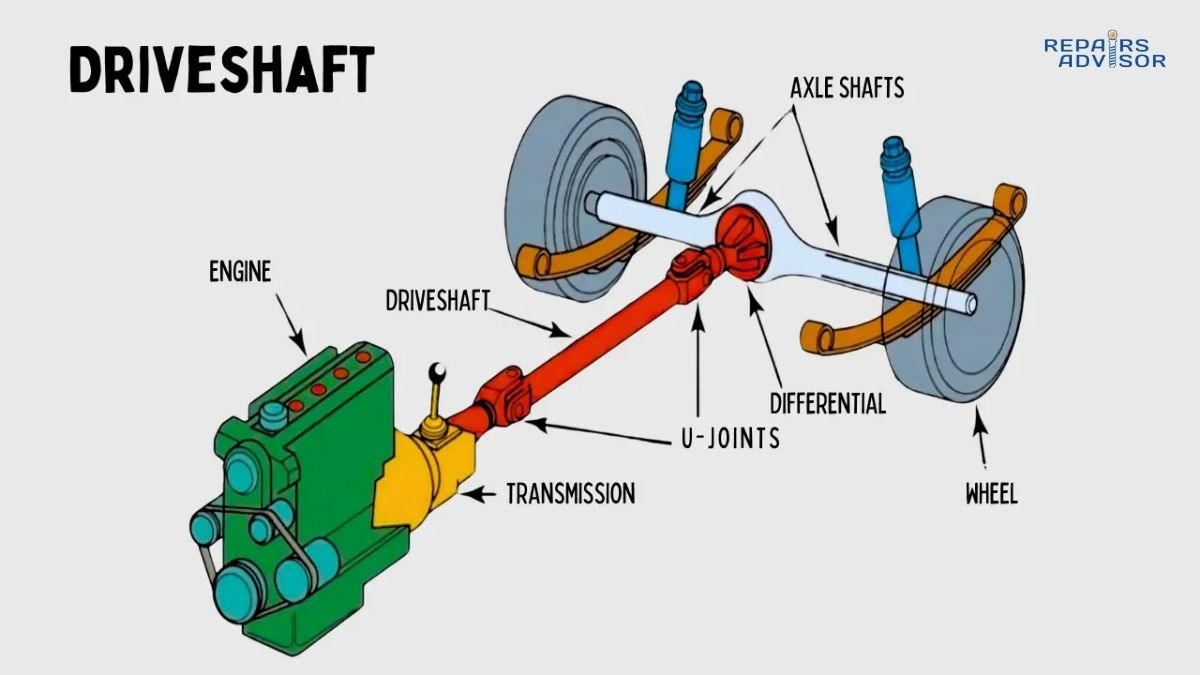

The strategic placement of bump stops varies depending on suspension design. The most common location is on the shock absorber or strut shaft itself, where the bump stop typically appears as a rubber or foam cylinder that floats on the damper rod. In this configuration, the bump stop contacts a mounting plate or the vehicle body when the suspension reaches full compression. Some vehicles mount bump stops between the frame and control arms, particularly in truck applications with solid axles. MacPherson strut suspensions often integrate bump stops into the strut assembly itself, sandwiched between the strut body and upper mounting plate. Pickup trucks frequently feature bump stops mounted to the frame directly above the rear axle, where they cushion contact during heavy load carrying or off-road articulation.

Understanding where bump stops live in your suspension system helps explain why some are easily accessible for inspection or replacement, while others require significant disassembly. Frame-mounted bump stops on trucks often require just crawling under the vehicle, while strut-integrated bump stops may necessitate removing the entire strut assembly and safely compressing the spring—a job requiring specialized tools and knowledge.

How Bump Stops Work Mechanically

The mechanical operation of bump stops demonstrates elegant engineering that balances seemingly contradictory goals: providing a soft, comfortable cushion during initial contact while delivering firm protection against hard bottoming. This balance comes from the progressive compression principle, where bump stops behave like variable-rate springs rather than simple rubber blocks.

When a bump stop first makes contact with its mating surface, it compresses relatively easily. This initial soft engagement, typically covering the first third of the bump stop’s travel, allows the suspension to use its full range of motion without creating a harsh, abrupt feeling. As compression continues into the middle third of travel, the bump stop’s resistance increases progressively. Material properties and geometric design work together to create this rising spring rate—the tapered or contoured shapes of most bump stops mean more material comes into compression as deflection increases. In the final third of travel, the bump stop provides maximum resistance, effectively preventing further compression while still cushioning the impact more gently than metal-to-metal contact would.

This progressive behavior explains why properly designed bump stops can improve ride quality rather than degrade it. Unlike a rigid mechanical stop that would create a harsh impact, a progressive bump stop allows the suspension to gradually transition from normal operation to maximum compression, maintaining some compliance even at the travel limit.

Material selection fundamentally determines how bump stops perform their protective role. Factory rubber bump stops represent the most common original equipment choice, offering adequate performance for normal driving conditions at low cost. Natural rubber compounds containing additives for ozone resistance typically use a Shore hardness rating around 65, though manufacturers select hardness values between 45 and 75 depending on application requirements. The geometry of rubber bump stops significantly affects their deflection characteristics—solid cylindrical rubber blocks permit only about 20% deflection when loaded in compression, while hollow rubber bump stops can achieve 50-75% deflection of their free height. This explains why many modern vehicles use hollow, progressively shaped rubber bump stops rather than simple solid cylinders.

Polyurethane bump stops dominate the aftermarket upgrade sector because this synthetic material offers superior durability compared to rubber. Polyurethane resists heat, oil, and environmental contaminants that cause rubber to deteriorate over time. This resistance translates to service lives two to three times longer than rubber equivalents. Polyurethane’s inherent firmness provides better protection for suspension components during hard use, making it the material of choice for performance applications. The trade-off comes in the form of a slightly firmer feel compared to rubber—polyurethane bump stops transfer more vibration to the chassis, though this characteristic often suits modified suspensions where component protection outweighs maximum comfort. Modern suspension spring systems work in concert with bump stops to create a complete suspension package that balances comfort and control.

The mechanism of force absorption involves converting kinetic energy into heat through material compression and internal friction. When the suspension compresses into the bump stop, the material deforms elastically, storing energy like a spring. Unlike steel springs that return virtually all stored energy during rebound, rubber and polyurethane materials dissipate a portion of that energy as heat through internal friction. This energy dissipation serves a protective function—it reduces the rebound forces that would otherwise bounce the suspension back down aggressively. Preventing aggressive rebound helps maintain tire contact with the road and reduces stress on suspension components.

The importance of preventing coil bind in spring suspensions cannot be overstated. Coil bind occurs when a coil spring compresses to the point where adjacent coils touch, eliminating all remaining spring travel. At this point, the spring behaves like a solid rod rather than a spring, transmitting impact forces directly through the suspension system. Coil bind can cause broken springs, damaged shock mounts, or bent suspension components. Bump stops engage before coil bind occurs, maintaining some cushioning effect even at maximum suspension compression. The relationship between bump stops and control arm bushings creates a complete isolation system that manages both normal suspension movement and extreme travel conditions.

Types of Bump Stops

Understanding the different types of bump stops available helps match the right component to your vehicle’s needs and usage patterns. From simple factory rubber pieces to sophisticated hydraulic units costing thousands of dollars, the bump stop market offers solutions for every application and budget.

Factory rubber and foam bump stops equip the vast majority of production vehicles, representing a balance between cost and performance adequate for normal driving conditions. Manufacturers typically use either molded rubber compounds or microcellular foam materials, with microcellular polyurethane foam becoming increasingly common in modern vehicles. These factory bump stops integrate easily into existing suspension designs, require no modifications for installation, and provide adequate protection for vehicles used within their design parameters. The primary limitation of factory bump stops emerges under heavy use—repeated compression cycles in off-road conditions or with heavy loads cause rubber to crack and foam to disintegrate. This deterioration process accelerates in environments with temperature extremes, exposure to petroleum products, or UV radiation from sunlight.

Replacement intervals for factory-style bump stops vary widely depending on usage. Daily drivers on paved roads might see rubber bump stops last the vehicle’s lifetime, while trucks used for regular towing or off-road vehicles may need replacement every 30,000-50,000 miles. Visual inspection during routine maintenance provides the best indication of when replacement becomes necessary.

Polyurethane aftermarket bump stops address the durability limitations of rubber through superior material properties. Polyurethane’s resistance to environmental degradation means these bump stops maintain their protective function far longer than rubber equivalents—service lives of 100,000+ miles are common even under demanding conditions. The firmness of polyurethane provides enhanced protection for suspension components during aggressive driving or heavy loads, making these upgrades popular among enthusiasts who have modified their vehicles with lowered or lifted suspensions. Lowered vehicles benefit particularly from polyurethane bump stops because reduced suspension travel means bump stops engage more frequently.

Aftermarket polyurethane bump stops come in various durometer ratings, allowing selection based on specific needs. Softer durometer polyurethane maintains more comfort while still outlasting rubber, while harder durometer versions maximize component protection during extreme use. Universal polyurethane bump stops accommodate various mounting configurations, making them suitable for custom applications or vehicles where specific replacement parts aren’t available. Installation typically requires no special tools beyond basic hand tools, though some applications benefit from silicone lubricant spray to ease tight-fitting pieces onto mounting studs.

Hydraulic bump stops, often called air bumps or nitrogen bump stops, represent the premium solution for off-road performance and racing applications. These sophisticated components function as miniature shock absorbers rather than simple cushions, incorporating pistons, compression and rebound valving, shock oil, and nitrogen pressure into compact cylindrical packages. The operation principle of hydraulic bump stops involves two distinct stages that work sequentially to control suspension movement.

During the first stage of hydraulic bump stop operation, the shaft compresses nitrogen gas contained in the cylinder. This nitrogen compression acts like a spring with an exponentially increasing spring rate—the more you compress it, the harder it pushes back. This characteristic allows the first portion of bump stop travel (typically the first 30-40% of stroke) to feel relatively soft, permitting full use of suspension travel without harsh impact. As compression continues into the middle third of travel, the nitrogen spring rate increases significantly, providing progressively firmer resistance.

The second stage begins when the bump stop piston enters the oil-filled portion of the cylinder. At this point, hydraulic damping comes into play as oil is forced through precisely calibrated orifices in the piston. This hydraulic damping slows the rate of compression, preventing harsh bottoming even during severe impacts. The combination of progressive nitrogen spring rate and hydraulic damping creates incredibly sophisticated control over the final portion of suspension travel. Premium hydraulic bump stops also incorporate rebound damping, controlling how quickly the bump stop extends after compression. This rebound control prevents the harsh clicking sound of bump stops fully extending and helps maintain suspension control during rapid compression-extension cycles over consecutive bumps.

Hydraulic bump stop sizing involves two critical specifications: cylinder diameter and stroke length. Cylinder diameter—available in 2.0-inch and 2.5-inch sizes—determines force capacity. The 2.0-inch diameter suits lighter vehicles under 5,000 pounds used for extreme off-roading like rock crawling, where slow speeds and precise control matter more than high-speed impact absorption. The larger 2.5-inch diameter handles heavier vehicles over 5,000 pounds and high-speed desert racing applications, where massive energy absorption becomes necessary. Stroke length options of 2, 3, or 4 inches determine how much travel the bump stop provides before reaching full compression. Internal spacers allow shortening longer-stroke bump stops when packaging constraints limit available space.

The installation complexity of hydraulic bump stops explains their premium pricing beyond just the parts cost. Unlike bolt-on rubber or polyurethane bump stops, hydraulic units require custom mounting brackets, typically fabricated from steel or aluminum. This fabrication necessitates cutting, welding, and painting skills, plus specialized tools for metal work. Proper installation also requires coordination with existing shock absorbers—active suspension systems and hydraulic bump stops must work together rather than fight each other. Professional installation by shops experienced with high-performance off-road suspensions ensures proper mounting, positioning, and integration with the overall suspension package. Cost for quality hydraulic bump stops ranges from $700-$1,000 per pair for the components alone, with installation adding several hundred to over a thousand dollars depending on fabrication complexity.

Why Bump Stops Are Critical

The critical nature of bump stops becomes apparent when examining the specific protection they provide and the expensive consequences of operating without them. Component protection represents the primary benefit, but the implications extend beyond simple parts preservation to encompass safety and vehicle longevity.

Shock absorbers and struts, costing $100-$400 each for quality replacements, suffer severe internal damage from bottoming without bump stop protection. When a shock’s piston slams into the end cap at full compression, the impact can bend the piston rod, damage internal valving, and rupture seals. This damage often isn’t immediately apparent—the shock may continue functioning but with degraded damping characteristics that compromise handling and ride quality. Repeated bottoming accelerates wear on all internal components, drastically shortening shock life. Some enthusiasts who regularly drive hard without proper bump stops find themselves replacing shocks annually rather than every 50,000+ miles as designed.

Suspension control arms face bending or cracking when they contact the frame without bump stop cushioning. Aluminum control arms particularly suffer from impact damage, as the material is less forgiving than steel when subjected to shock loads. Even steel arms can bend if subjected to repeated hard impacts, throwing off suspension geometry and potentially causing handling issues or tire wear. Repairing bent suspension arms requires specialized alignment equipment to measure geometry accurately, and replacement arms can cost $200-$500+ each depending on the vehicle.

Frame damage represents the most expensive consequence of missing bump stops. When suspension components repeatedly impact the frame rails at full compression, the welds or metal itself can crack. Frame damage often goes unnoticed until it becomes severe, potentially compromising structural integrity in an accident. Repairing frame damage requires specialized equipment and expertise, with costs easily reaching thousands of dollars.

Tire damage from fender contact might seem minor but creates safety hazards. When tires rub against fender wells during hard compression, the sidewall can sustain cuts or damage. Since sidewall damage compromises tire structural integrity, even small cuts often necessitate tire replacement. For vehicles with large aftermarket wheels and tires costing $300+ each, this damage adds up quickly.

Specific driving conditions make bump stops transition from helpful to absolutely essential. Off-road driving subjects suspensions to impacts that factory engineers never anticipated. Rock crawling involves slow-speed, high-articulation situations where suspension travel frequently reaches maximum compression. Trail running at moderate speeds combines frequent bumps with unpredictable terrain, creating scenarios where bump stops engage repeatedly. Desert racing pushes suspension systems to their absolute limits, with high-speed impacts generating forces that can destroy components in seconds without proper bump stops.

Heavy load hauling transforms suspension behavior dramatically. When a truck carries maximum payload or tows near its capacity, suspension sag reduces available travel significantly. This reduced travel means bump stops engage more frequently, making their condition critical for protecting both suspension and cargo. Worn or missing bump stops on a heavily loaded truck can lead to harsh impacts that jar cargo loose or damage sensitive equipment being transported.

Lowered vehicles present unique bump stop challenges because reducing ride height decreases suspension travel proportionally. A vehicle lowered two inches might have 40% less total suspension travel than stock, meaning bump stops must engage earlier and provide protection within a compressed operating range. Many lowering kit installations require shortened bump stops or progressive polyurethane pieces designed specifically for reduced travel applications. Failure to address bump stops when lowering a vehicle often results in harsh ride quality and accelerated suspension wear.

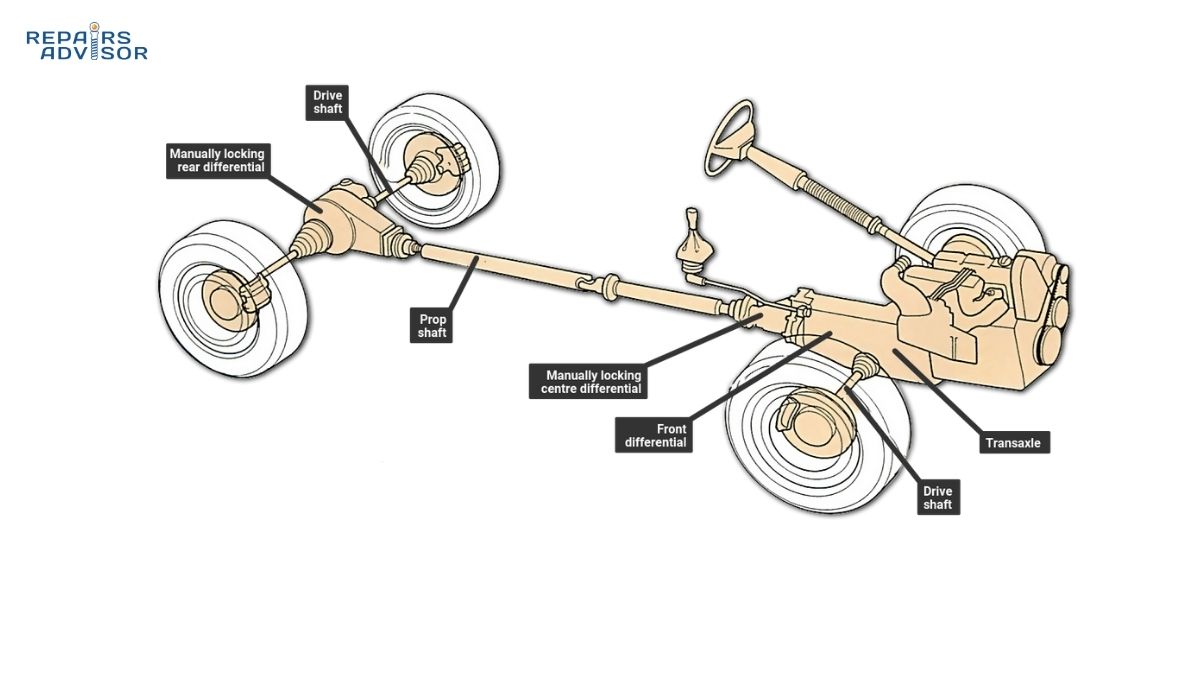

Lifted vehicles face opposite challenges—increased suspension travel and articulation capability mean bump stops might need to be taller or relocated to prevent excessive travel that could damage driveline components. Lifted trucks without properly modified bump stops risk over-extending CV axles or binding driveshafts at full articulation.

The financial implications of neglecting bump stops become clear when considering replacement costs. Failed shock absorbers requiring premature replacement cost $400-$1,600 for a full set with installation. Bent control arms add $500-$2,000+ depending on the vehicle and whether alignment is affected. Frame damage repair can exceed $3,000-$5,000 for significant issues. Against these potential costs, bump stop replacement typically runs $50-$200 for a complete set of quality polyurethane pieces, making them one of the highest-value maintenance items in automotive repair.

Signs of Worn or Missing Bump Stops

Recognizing the symptoms of worn or missing bump stops enables proactive replacement before expensive damage occurs. The challenge lies in distinguishing bump stop issues from other suspension problems, as symptoms often overlap with worn shocks, damaged bushings, or other suspension wear.

Audible symptoms provide the most obvious indication that bump stops aren’t performing their job. Metallic clunking sounds when driving over bumps—particularly sharp, harsh sounds rather than the muffled thuds of normal suspension operation—often indicate metal-on-metal contact that bump stops should prevent. These sounds typically occur over speed bumps, potholes, or rough roads where suspension compression reaches its limits. The clunking might be accompanied by a slight delay or rebound sensation as the suspension recovers from bottoming out.

Harsh bottoming sounds differ from normal suspension operation in their sharpness and finality. Properly functioning bump stops create a progressive resistance that you might feel but rarely hear. When that progression is missing, compression ends abruptly with a definitive bang or crash. Railroad tracks or severe dips in the road that cause maximum suspension compression reveal these sounds most clearly.

Changes in ride quality often provide earlier warning than audible symptoms. An unusually harsh ride over bumps that previously felt manageable suggests bump stops have deteriorated to the point where they’re no longer cushioning impacts effectively. This harshness differs from the gradual ride quality degradation that comes from worn shocks—bump stop deterioration creates a more sudden, impact-oriented harshness rather than general bounciness or poor damping.

Increased vibration transmission to the cabin accompanies worn bump stops because damaged or missing bump stops allow more direct force transfer from suspension to body. You might notice that impacts you barely felt before now jar the entire vehicle, or that vibrations seem sharper and less filtered than normal.

Physical inspection reveals bump stop condition definitively but requires examining components that may be difficult to access. Visible cracking appears first around stress points where the bump stop flexes most during compression. Rubber bump stops show weathering as surface cracks that gradually deepen, while foam pieces might crumble when touched. Complete disintegration represents advanced deterioration—many technicians find only remnants of bump stops when inspecting older vehicles or those used in harsh conditions. The bump stop material might have compressed into hard, brittle chunks barely recognizable as the original component.

Suspension sagging under load that seems excessive compared to the vehicle’s rated capacity might indicate bump stop failure. When bump stops deteriorate, they can’t support the final portion of suspension travel, allowing the vehicle to sit lower than designed when loaded. This sagging becomes particularly noticeable when comparing side-to-side—if one bump stop has failed while the other remains functional, the vehicle might sit noticeably lower on one side when loaded.

Excessive body roll in corners can indicate bump stop problems, particularly if control arms or bushings are otherwise sound. Some aftermarket bump stops incorporate roll resistance features, and when these components fail, cornering feel changes noticeably. The vehicle might lean more than normal or feel less controlled when transitioning from straight-line to turning.

Trailer sway when towing provides another indicator, especially on trucks where bump stops help control rear suspension under trailer tongue weight. Worn rear bump stops allow excessive rear suspension compression, changing the vehicle’s geometry and potentially contributing to trailer instability. If a truck that previously towed confidently suddenly exhibits trailer sway issues, checking rear bump stops should be part of the diagnostic process.

Regular inspection intervals prevent surprise failures. Check bump stops during routine maintenance—oil changes provide an opportunity if the vehicle is already on a lift. Shock or strut replacement always requires bump stop inspection since accessing the shocks often means working around the bump stops. After off-road trips or driving in harsh conditions, visual inspection helps catch damage before it progresses. Many enthusiasts make bump stop inspection part of their pre-trip routine before long journeys or off-road adventures.

Bump Stop Replacement Considerations

Determining when bump stop replacement becomes necessary involves assessing both component condition and usage patterns. Understanding the complexity levels of different replacement scenarios helps decide between DIY repair and professional service.

Replacement timing guidelines depend on driving conditions and vehicle use. Visible damage or deterioration always warrants immediate replacement—cracked, brittle, or missing bump stops can’t perform their protective function. Complete disintegration discovered during inspection requires urgent replacement since the suspension is operating without any bump stop protection. Ride quality degradation that manifests as harsh bottoming or impact sounds suggests bump stop effectiveness has diminished even if visual damage isn’t apparent. During shock or strut replacement, always replace bump stops regardless of their apparent condition—the relatively low cost of new bump stops provides insurance against shortened shock life, and the labor to access them is already being performed.

Suspension modifications fundamentally change bump stop requirements. Lowering springs reduce available suspension travel, requiring shorter bump stops or progressive designs that engage earlier. Lift kits increase suspension travel but may require relocated or extended bump stops to prevent over-extension damage to CV axles or driveline components. Control arm bushing replacement presents an ideal opportunity to inspect and replace bump stops since the suspension is already partially disassembled.

The DIY versus professional installation decision depends on bump stop type and accessibility. Beginner-friendly installations include simple bolt-on replacements on trucks where bump stops mount to the frame above the axle with visible, accessible hardware. These installations typically require only basic hand tools, a jack, and jack stands. Removing two or three bolts, pulling the old bump stop, and installing the new piece takes perhaps 30 minutes per side. Rubber bump stops on accessible truck suspensions fall into this category.

Intermediate-difficulty installations involve strut-mounted bump stops that require spring compression. This work demands a quality spring compressor tool and understanding of the dangers involved—compressed springs store enormous energy that can cause serious injury if released unexpectedly. The process involves safely supporting the vehicle, removing the strut assembly, compressing the spring, disassembling the strut mount, replacing the bump stop, and reassembling everything with proper torque specifications. While mechanically inclined DIYers can handle this work, the safety risks make professional service worth considering if you lack experience or proper tools. Many MacPherson strut designs integrate bump stops into the strut mount assembly, simplifying replacement but requiring strut removal.

Professional installation becomes mandatory for hydraulic bump stops due to custom fabrication requirements. Installing hydraulic bumps involves cutting factory bump stop mounts, fabricating custom brackets (often requiring TIG welding aluminum or MIG welding steel), precisely positioning the bump stops relative to shock absorbers, and ensuring proper clearance at full compression and extension. Shops specializing in off-road suspensions or performance fabrication possess the expertise, tools, and experience to execute these installations correctly. Attempting hydraulic bump stop installation without proper welding skills, fabrication knowledge, or suspension geometry understanding risks creating a setup that doesn’t function properly or even damages other components.

Safety considerations during bump stop replacement center on proper vehicle support and spring handling. Always use jack stands rated for your vehicle’s weight—never work under a vehicle supported only by a hydraulic jack. Position jack stands on solid chassis points specified in the vehicle’s service manual. When working with suspension components, support the suspension arm or axle with a secondary jack to prevent sudden dropping when fasteners are removed.

Warning: Suspension work involves compressed springs and heavy components capable of causing serious injury. Properly support the vehicle with appropriate jack stands before working underneath. Never rely solely on hydraulic jacks for support. When working with strut assemblies, use quality spring compressors and wear safety glasses. Compressed springs store significant energy and can cause severe injury if released unexpectedly.

Important: Hydraulic bump stops require custom mounting that typically involves welding and fabrication. Improper installation can compromise suspension function, create interference issues, or even damage other components. Professional installation by experienced fabricators ensures proper integration with your vehicle’s suspension system.

Installation tips improve success rates for DIY replacement. Silicon spray lubricant helps tight-fitting rubber bump stops slide onto mounting studs without tearing. Apply lubricant to both the mounting surface and the bump stop’s inner bore, then work the bump stop onto the stud with a twisting motion. For particularly stubborn installations, heating the rubber bump stop slightly with a heat gun (not a torch) makes the material more pliable.

Always replace bump stops in pairs—both sides of an axle should use matching components to maintain balanced suspension behavior. Replacing only one side can create uneven ride characteristics or handling imbalances.

Verify tire clearance at full compression before finalizing the installation. With the vehicle on jack stands and the suspension supported by a floor jack, cycle the suspension through its travel range while checking for tire-to-fender contact. If the bump stop doesn’t engage before contact occurs, you may need taller bump stops or your suspension setup requires adjustment.

Check the bump stop gap at full droop (maximum extension). The bump stop should be close to the coil spring but not touching when the suspension is fully extended. If the bump stop contacts the spring at normal ride height or full extension, it will create unwanted spring preload and harsh ride quality. Adjust the bump stop position or consider shorter pieces if clearance is insufficient.

Bump Stops in Performance and Off-Road Applications

The role of bump stops expands dramatically in performance and off-road applications, transforming from simple protective devices into active suspension tuning components. Understanding how motorsports and off-road enthusiasts use bump stops reveals sophisticated approaches to suspension control that benefit from the progressive characteristics these components provide.

Suspension tuning with bump stops enables chassis balance adjustments without changing primary spring rates. Race engineers use bump stops to limit suspension travel under specific loading conditions, preventing excessive compression that would degrade handling. For example, limiting rear suspension travel during hard acceleration on a rear-wheel-drive car prevents the rear wheels from gaining too much negative camber, which would reduce available traction and drive force. By choosing a bump stop that engages at a specific point in suspension travel, engineers can progressively increase the effective spring rate as compression increases, allowing a softer main spring for better compliance over small bumps while still controlling body motion during aggressive driving.

The same principle applies to front suspension during heavy braking. Limiting how much the front suspension compresses prevents excessive nose dive that would affect steering geometry and weight transfer. Progressive bump stops allow enough front compression for proper weight transfer to maximize braking force while preventing geometry changes that degrade steering feel.

This suspension tuning approach offers a significant advantage—it allows running softer main springs than would otherwise be possible. Softer springs provide better ride quality over small road irregularities and help maintain tire contact on bumpy surfaces. The bump stops add progressive resistance only when needed, creating a suspension that feels compliant during normal driving but firms up automatically under high loads.

Off-road specific benefits explain why serious off-roaders invest in premium bump stop systems. The constant bottoming experienced during rock crawling, high-speed desert running, or aggressive trail riding subjects suspension components to punishing impacts that would quickly destroy systems designed only for pavement. Quality bump stops absorb this constant stress, dissipating energy that would otherwise damage shocks, bend control arms, or crack frame mounts.

Better vehicle control on rough terrain comes from the damping characteristics of hydraulic bump stops. When the suspension compresses into a hydraulic bump stop during a hard impact, the controlled damping prevents the harsh rebound that would bounce the tire off the ground. Maintaining tire contact improves traction, steering control, and vehicle stability—critical factors when navigating technical terrain at any speed.

High-speed desert racing pushes bump stops to their absolute limits. In this environment, suspension components can compress through their entire travel range in fractions of a second when hitting bumps at 60-80+ mph. The energy involved in these impacts is massive—hydraulic bump stops absorb and dissipate this energy through their progressive spring action and hydraulic damping, preventing hard bottoming that would destroy conventional suspension components. Desert racers typically run the largest available hydraulic bump stops (2.5-inch diameter with 4-inch stroke) to maximize energy absorption capacity. The relationship between double wishbone suspension geometry and bump stop placement significantly affects how forces transfer through the chassis.

Packer systems enable fine-tuning bump stop engagement without changing the bump stops themselves. Packers are small polymer spacers of varying thicknesses that stack on the shock shaft below the bump stop. Adding packers effectively shortens the available suspension travel before the bump stop engages, while removing packers allows more travel. This adjustability proves invaluable during suspension development or trackside tuning.

Two packer styles exist: solid rings and slotted rings. Solid ring packers require removing the shock from the vehicle and disassembling it to change packer stack height—a time-consuming process suitable for initial setup or major changes. Slotted packers feature a slot cut through one side, allowing them to snap over the shock shaft with the spring still in place. This design enables quick trackside adjustments without removing shocks, making it popular in racing where setup changes between sessions help optimize performance.

Professional race teams often carry multiple packer combinations to dial in suspension behavior for different track conditions. A rough, bumpy track might require less packer thickness to allow more suspension travel before bump stop engagement, while a smooth track with high cornering loads might benefit from more packer thickness to limit body roll. The ability to adjust bump stop engagement points provides another tuning variable beyond spring rates, damper settings, and anti-roll bar stiffness.

Advanced enthusiasts experiment with progressive packer combinations—using softer material for the first packer and harder material for subsequent packers creates multi-stage progression that mimics expensive hydraulic bump stops at lower cost. This approach requires experimentation and careful selection of packer materials with different shore hardness ratings.

Common Misconceptions About Bump Stops

Several persistent myths about bump stops lead to neglect or inappropriate modifications that compromise suspension performance and component longevity. Clearing up these misconceptions helps vehicle owners make informed decisions about maintenance and upgrades.

The belief that “bump stops don’t do much” represents perhaps the most damaging misconception. This myth likely stems from bump stops’ invisibility during normal driving—when functioning properly, you shouldn’t notice them at all. However, their absence becomes immediately apparent when suspension components begin suffering damage from repeated bottoming. The thousands of dollars in potential repair costs prevented by functioning bump stops dramatically outweigh the modest expense of maintaining these components.

Another common myth suggests bump stops are “only needed for off-roading.” While off-road use certainly stresses bump stops more than street driving, even daily drivers benefit from proper bump stop function. City driving involves speed bumps, potholes, and expansion joints that compress suspensions to their limits. Parking garage ramps, especially when entered at speed, can bottom out suspensions. Emergency maneuvers that load suspension heavily during hard braking or quick direction changes rely on bump stops to prevent damage during these extreme but possible events.

The misconception that “stiffer is always better” overlooks the importance of progressive compression characteristics. Excessively stiff bump stops create harsh impacts rather than smooth transitions, potentially causing more damage than they prevent. The jarring impact of hitting an overly stiff bump stop can shock-load suspension components, creating stress risers in metal parts. Progressive compression that gradually increases resistance provides better protection while maintaining some compliance even at travel limits.

Some believe bump stops “increase load capacity,” leading to dangerous overloading. Bump stops do not increase your vehicle’s rated load capacity—they support the existing suspension system in managing loads within the vehicle’s designed limits. The manufacturer’s maximum load rating accounts for the complete suspension system including springs, shocks, and bump stops. Adding upgraded bump stops doesn’t magically allow carrying more weight; it simply better protects components when operating near capacity. Exceeding load ratings risks frame damage, brake system overload, and handling degradation that bump stops cannot prevent.

The idea that “you can skip replacement” when bump stops appear only slightly damaged fails to account for the progressive nature of deterioration. Bump stops that show surface cracking will soon develop deep cracks that compromise material integrity. Waiting until complete failure risks the expensive damage bump stops exist to prevent. Preventive replacement when deterioration becomes visible costs far less than repairs needed after operating without bump stop protection.

Conclusion

Bump stops exemplify how small, inexpensive components can prevent thousands of dollars in damage while maintaining the ride quality and handling characteristics that make vehicles pleasant to drive. Their role as progressive-rate cushions protecting suspension systems from the consequences of maximum compression becomes critical whether you’re navigating city streets, hauling heavy loads, or pushing performance limits on track or trail.

Regular inspection during routine maintenance provides the best opportunity to catch bump stop deterioration before expensive consequences develop. The few minutes required to visually examine bump stops during oil changes or tire rotations can reveal cracking, compression, or complete deterioration that warrants replacement. This inspection becomes particularly important when replacing shocks or struts, as the labor to access bump stops is already being performed.

Understanding the different types of bump stops available helps match components to your specific needs. Factory rubber or foam pieces suit unmodified vehicles used within design parameters, while polyurethane upgrades offer durability for modified vehicles or demanding use. Hydraulic bump stops provide ultimate performance for serious off-road or racing applications, though their cost and installation complexity limit them to enthusiast builds where the investment makes sense.

The symptoms of worn bump stops—metallic clunking, harsh bottoming, or changed ride quality—should prompt immediate inspection rather than being dismissed as “just an old car.” These symptoms indicate suspension components are experiencing impacts they weren’t designed to absorb, accelerating wear throughout the system.

When to Consult a Professional:

Professional consultation becomes necessary for several bump stop related situations. Complex strut-mounted bump stop replacement that requires spring compression warrants professional service if you lack the tools or experience to safely handle compressed springs. Hydraulic bump stop installation absolutely requires professional fabrication skills—the custom welding and precise positioning demand expertise that most DIYers don’t possess. Suspension modifications like lowering or lifting should include professional assessment of bump stop requirements to ensure adequate travel control in the modified configuration. Any suspension damage diagnosis benefits from professional expertise, as bump stop issues often occur alongside other suspension problems that require comprehensive evaluation. Finally, if ride quality concerns or handling changes follow bump stop replacement, professional alignment and suspension geometry check ensures nothing else needs attention.

Final Recommendation: Make bump stop inspection part of every suspension service interval. Check these components when performing shock or strut replacement, lowering or lifting your vehicle, or any time you’re performing maintenance that provides access to suspension areas. The $50-$200 cost of a complete bump stop replacement represents exceptional value considering it prevents potential damage costing thousands. Quality bump stops from reputable manufacturers last for years under normal conditions, making this one of the most cost-effective protective maintenance items in automotive care.

For vehicles used in demanding conditions—regular towing, frequent off-road use, or modified suspensions—consider upgrading to polyurethane bump stops that offer superior durability. The modest additional cost over rubber replacements pays dividends in extended service life and better component protection.

Whether you drive a daily commuter, weekend off-roader, or dedicated performance vehicle, functioning bump stops provide insurance against expensive suspension damage while maintaining the ride quality and handling that keep driving enjoyable. Don’t overlook these critical components when planning maintenance or investigating suspension concerns.