Your automatic transmission contains one of the most engineered fluids in your vehicle—automatic transmission fluid (ATF) is far more than just a lubricant. This specialized hydraulic fluid simultaneously lubricates moving parts, transmits power through the torque converter, cools internal components, and protects against wear—all while enduring temperatures from -40°F to nearly 400°F.

Unlike engine oil, which primarily lubricates, ATF performs multiple critical functions that directly affect how your transmission shifts, how long it lasts, and whether it fails prematurely. Understanding the differences between DEXRON, MERCON, and proprietary fluid specifications isn’t just technical trivia—using the wrong fluid type can cause transmission damage within thousands of miles and potentially void your warranty.

The complexity has increased significantly in recent years. Where a single “universal” ATF once served most vehicles, today’s market offers over a dozen distinct specifications. Manufacturers have moved away from universal fluids toward vehicle-specific formulations, each engineered for particular friction characteristics, viscosity grades, and thermal properties. Add in the distinctions between traditional automatic transmissions, continuously variable transmissions (CVTs), and dual-clutch transmissions (DCTs)—each requiring completely different fluids—and the confusion is understandable.

This guide cuts through that complexity. You’ll learn what ATF actually does inside your transmission, how to decode specification labels, when fluid changes are truly necessary versus manufacturer marketing, and how to recognize warning signs before minor issues become expensive repairs. Whether you’re a DIY enthusiast considering your first transmission fluid change or simply want to make informed decisions about professional service, understanding automatic transmission fluid protects both your wallet and your vehicle’s longevity.

For context on how ATF operates within the broader transmission system, see our detailed explanation of how automatic transmissions work. Understanding how torque converters work also provides valuable insight into ATF’s role in power transmission.

Safety Note: All transmission fluid service procedures require appropriate safety equipment and precautions. High-temperature fluid can cause severe burns. Any transmission work requiring vehicle lift should be performed only by qualified technicians with proper equipment and training.

What is Automatic Transmission Fluid and What Does It Do?

ATF Composition and Engineering

Automatic transmission fluid represents sophisticated chemical engineering, with each formulation containing 10-20 different additives carefully balanced to meet specific performance requirements. The base oil—either mineral or synthetic—provides fundamental lubricating properties, but the additive package is what truly distinguishes one ATF from another and determines its suitability for particular transmissions.

Friction modifiers are perhaps the most critical component. These additives control how clutch packs engage and release during gear changes. The right friction characteristics produce smooth, imperceptible shifts; incorrect friction properties cause harsh engagement, shudder, or slipping. Ford’s Type F fluid specifically excludes friction modifiers to provide firmer, more positive shifts in older transmissions, while modern formulations like DEXRON VI contain sophisticated friction modifier blends that maintain consistent performance throughout the fluid’s service life.

Viscosity index improvers maintain consistent thickness across extreme temperature ranges. ATF must flow freely at -40°F for cold starts in northern winters while maintaining adequate film strength at operating temperatures approaching 400°F under heavy loads. This 440-degree temperature span demands exceptional viscosity stability that mineral oils alone cannot provide—hence the industry trend toward synthetic base stocks.

Detergents and dispersants perform critical cleaning functions, keeping wear particles and combustion contaminants suspended in the fluid until they can be trapped by the filter. Without these additives, varnish accumulates on valve body components, causing sticky solenoids and erratic shifting. Anti-wear additives, typically zinc and phosphorus compounds, protect metal-to-metal contact surfaces when lubricating film is momentarily compromised under high loads or during gear changes.

Seal conditioners maintain elasticity in rubber seals and gaskets, preventing the hardening and shrinkage that leads to leaks. Anti-foam agents prevent aeration when the fluid is churned at high speeds through planetary gearsets and valve body passages—foamy fluid compresses under pressure, causing spongy pedal feel and delayed shifts. Corrosion inhibitors protect internal metal surfaces from rust and oxidation, particularly important in transmissions that see infrequent use or operate in humid climates.

The precision of this chemical balance explains why ATF specifications are so specific and why substituting incorrect fluid types causes problems. Each transmission design anticipates particular friction characteristics, viscosity behavior, and thermal properties. Even small deviations from specification can produce noticeable performance changes.

Multiple Critical Functions Explained

Hydraulic Power Transmission is ATF’s primary mechanical function. In your automatic transmission, fluid pressure operates everything from clutch pack engagement to shift valve movement. The fluid must maintain precise viscosity—thick enough to sustain pressure without excessive leakage past seals, yet thin enough to flow rapidly through narrow passages for responsive shifts.

When you accelerate from a stoplight, transmission fluid pressure clamps clutch packs together to lock specific planetary gear combinations. Too-thick fluid causes delayed engagement and sluggish shifts because pressure builds slowly. Too-thin fluid allows pressure to bleed past seals faster than the pump can build it, resulting in slipping and premature clutch wear. Operating temperature dramatically affects viscosity, which is why transmissions have narrow optimal temperature ranges—typically 175-225°F.

Inside the torque converter, ATF transmits engine power to the transmission input shaft through fluid coupling alone—there’s no mechanical connection during normal driving until lockup clutch engages. The fluid circulates from impeller to turbine at speeds exceeding 2,000 RPM, multiplying torque during acceleration. This violent fluid motion generates significant heat, which is why torque converters are major heat sources in automatic transmissions.

Lubrication protects every moving component—planetary gear teeth, bearing surfaces, clutch splines, valve body components—from metal-to-metal contact that would cause immediate wear. Unlike engine bearings that operate in continuous oil bath, transmission components experience sliding contact under high loads during torque transfer. The fluid must maintain adequate film strength even when squeezed between clutch plates that are clamping together with 500+ pounds of force.

The planetary gearsets and valve bodies inside your transmission contain dozens of precisely machined components with tolerances measured in thousandths of an inch. Even microscopic wear particles can jam valve body passages or cause solenoids to stick. This is why fluid cleanliness is so critical—the filter alone doesn’t capture particles below 30-40 microns, so the detergent additives must keep smaller contaminants suspended rather than allowing them to settle and form abrasive sludge.

Cooling prevents transmission failure under sustained loads. Every gear change dissipates energy as heat—the more power your engine produces and the more frequently you shift, the more heat generation. Towing, mountain driving, and aggressive acceleration in high-performance vehicles can push transmission temperatures beyond 300°F, at which point fluid begins rapid oxidation and additive depletion.

Most vehicles route ATF through a transmission cooler integrated into the engine radiator. Some high-performance or heavy-duty applications add supplemental air-to-oil coolers. The fluid circulates continuously, absorbing heat from clutch packs and bearing surfaces, then releasing it through the cooler. Degraded fluid with depleted additives loses heat transfer efficiency, creating a cascading failure scenario—hotter operation accelerates further degradation, which reduces cooling, which increases temperatures even more.

Cleaning and Protection through chemical additives extends transmission life by preventing the buildup that causes premature failure. Fresh ATF is transparent and bright red because it’s chemically clean. As mileage accumulates, the fluid darkens as detergents suspend microscopic wear particles, clutch friction material, and oxidation products. This is normal—dark fluid isn’t automatically bad as long as it hasn’t reached the black, burnt stage indicating severe degradation.

The key is understanding that fluid has finite cleaning capacity. Once detergent additives are saturated with contaminants and anti-oxidation compounds are depleted, the fluid can no longer protect effectively. At this stage, varnish begins forming on valve body surfaces, wear accelerates, and the fluid takes on the burnt smell indicating thermal breakdown. This is why regular fluid changes are preventive maintenance—you’re replacing the fluid before its chemical additives are exhausted, not after damage has occurred.

For deeper understanding of how fluid chemistry affects friction characteristics, see our detailed explanation of how ATF and friction materials work. The transmission mechatronics that control modern transmissions depend entirely on ATF maintaining precise hydraulic properties.

For Beginners: Think of ATF as your transmission’s life support system. It’s simultaneously the blood (carries away heat and contaminants), the muscles (applies hydraulic force to shift gears), the cushion (lubricates moving parts), and the cleaning crew (prevents buildup). Without proper fluid, even the most expensive transmission fails quickly.

ATF Specifications and Types – Understanding the Alphabet Soup

Major OEM Specifications Decoded

The confusing array of ATF specifications exists because each automaker engineers transmissions with specific performance characteristics, then develops fluid formulations optimized for those designs. What works perfectly in a GM transmission may cause problems in a Ford or Honda unit because friction characteristics, hydraulic pressures, and thermal demands differ.

General Motors DEXRON Series represents the most widely recognized specification family. DEXRON III and its companion MERCON standard (developed jointly with Ford) dominated the market from the late 1990s through the mid-2000s, appearing in GM, Ford, many Asian vehicles, and even some European applications. The bright red fluid was cheap, widely available, and performed adequately in most automatic transmissions of its era.

DEXRON VI arrived in 2006 as GM transitioned to more efficient, higher-speed transmissions with tighter tolerances. The improved formulation offers better oxidation resistance, extended service intervals, and enhanced low-temperature fluidity. Critically, DEXRON VI is backward compatible—you can use it in transmissions that originally specified DEXRON III without problems. However, mixing the two dilutes the DEXRON VI benefits, so complete drain-and-fill is preferable to simple top-off.

The introduction of DEXRON ULV (ultra-low viscosity) in 2017 marked a significant departure. Developed jointly by GM and Ford for their new 10-speed automatic transmissions, this remarkably thin fluid reduces internal friction losses to maximize fuel economy—critical for meeting increasingly stringent CAFE standards. The reduced viscosity means ULV fluid provides less film strength than traditional ATF, requiring more sophisticated additive packages and tighter manufacturing tolerances. Critical warning: DEXRON ULV is NOT backward compatible with earlier DEXRON fluids despite the similar name. Using ULV in a transmission designed for DEXRON III or VI causes inadequate lubrication and potential damage.

Ford MERCON Specifications follow parallel evolution. MERCON V, introduced in the early 2000s, served most Ford, Mercury, and Lincoln vehicles through 2017, along with Mazda B-Series trucks and early Tribute models built on Ford platforms. MERCON LV (low viscosity) appeared in 2009, offering improved fuel economy through reduced internal friction—similar benefits to DEXRON VI but with Ford-specific friction characteristics.

MERCON ULV mirrors GM’s ultra-low viscosity development, introduced for the same co-developed 10-speed transmission. If your Ford F-150, Mustang, or other Ford product with 10-speed automatic was built after 2017, it requires MERCON ULV—and only MERCON ULV. The naming similarity between MERCON LV and ULV has caused expensive mistakes. Despite both being “low viscosity,” they are not interchangeable. The “U” for “ultra” isn’t just marketing—it indicates a significantly different viscosity grade that older transmissions aren’t designed to handle.

Ford’s Type F specification, now essentially obsolete, deserves mention for its distinct approach. Pre-1977 Ford transmissions and select Japanese imports required fluid without friction modifiers for firmer, more positive shifts. The lack of friction modifiers means Type F provides almost clutch-to-clutch engagement—desirable in performance applications and older designs, catastrophic in modern transmissions expecting smooth, modulated shifts.

Chrysler/Mopar ATF+4 demonstrates manufacturer-specific formulation at its most stringent. Introduced in the mid-1990s, this synthetic-blend fluid is specifically not compatible with DEXRON or MERCON fluids. Chrysler engineered their transmissions around ATF+4’s particular friction characteristics and thermal properties. Using DEXRON or MERCON in a Chrysler transmission requiring ATF+4 causes incorrect shift feel, accelerated clutch wear, and potential transmission damage. The reverse is equally problematic—ATF+4 contains additives that can cause problems in transmissions designed for DEXRON/MERCON fluids. This isn’t marketing or profit motive; it’s genuine engineering specificity.

Asian Manufacturer Specifications reflect similar engineering precision. Toyota’s distinction between Type T-IV (pre-2004) and WS (World Standard, 2004 and later) isn’t arbitrary. The WS formulation was developed specifically for Toyota’s second-generation hybrid transmissions and provides the friction characteristics necessary for smooth electric motor/gasoline engine transitions. Using Type T-IV in a transmission requiring WS—or vice versa—causes shift quality issues and accelerates clutch wear.

Honda’s DW-1 specification (later refined to ATF-Z1) reflects Honda’s unique transmission designs. Honda automatics have historically been sensitive to fluid specifications, with reports of premature transmission failure when owners used non-Honda-approved fluids. While multi-vehicle fluids claiming Honda compatibility exist, Honda dealerships and transmission specialists consistently recommend genuine Honda ATF for maximum reliability.

Nissan’s Matic-D, -J, -K, and -S specifications correspond to different transmission families across their vehicle lineup. Using the wrong Matic fluid variant causes shift quality issues and, in some cases, mechanical problems. The alphabetical progression doesn’t indicate backward compatibility—each letter represents a distinct formulation for specific transmission designs.

CVT and DCT: Completely Different Requirements

Continuously variable transmissions demand entirely different fluid formulations than conventional automatics. Where traditional ATF is optimized for clutch pack friction, CVT transmissions require fluid engineered for steel belt or chain sliding against variable-diameter pulleys. The friction characteristics are opposite—CVT fluid must allow controlled slip at the belt-pulley interface while preventing belt slippage under load. Using conventional ATF in a CVT causes immediate, severe damage to the friction surfaces and belt.

Each manufacturer typically specifies proprietary CVT fluid: Honda CVTF, Nissan NS-2 and NS-3, Toyota CVTF FE, Subaru CVTF-II. “Universal” CVT fluids exist and may be acceptable, but manufacturer-specific formulations are strongly recommended—CVT repairs are exceptionally expensive, often exceeding $5,000, making the $30-40 premium for OEM fluid insignificant.

Dual-clutch transmissions occupy middle ground between manual and automatic, and their fluid requirements reflect this. Some DCTs (like VW/Audi DSG units) use fluids similar to manual transmission oil, while others (like Ford PowerShift) require specific ATF formulations. The wet-clutch packs in DCTs demand precise friction characteristics different from both conventional automatics and CVTs. Always verify your specific DCT fluid requirement—assumptions based on “it’s sort of like an automatic” lead to expensive mistakes.

Multi-Vehicle Synthetic ATF and Compatibility

Modern multi-vehicle synthetic ATF products like Valvoline MaxLife Multi-Vehicle or Castrol Transmax Universal represent impressive chemical engineering. These fluids carry multiple OEM approvals—DEXRON III/VI, MERCON LV, Toyota Type T-IV/WS, Honda DW-1—and meet the performance requirements of dozens of different transmission designs. For many applications, quality multi-vehicle fluids provide excellent performance and convenience.

However, understand the limitations. Multi-vehicle fluids are NOT compatible with ultra-low viscosity specifications (DEXRON ULV, MERCON ULV), CVT transmissions, or certain manufacturer-specific requirements like Chrysler ATF+4. They represent a “greatest common denominator” approach—optimized for broad compatibility rather than maximum performance in any specific transmission. For high-mileage vehicles, heavy towing applications, or performance use, manufacturer-specific fluid often provides superior protection.

The backward compatibility principle generally holds: higher specification numbers can replace lower ones (DEXRON VI replacing DEXRON III), but never assume compatibility without verification. The jump to ultra-low viscosity fluids broke this pattern—ULV specifications are NOT backward compatible despite being “newer.”

Professional Insight: The automotive industry’s trend toward lower-viscosity fluids reflects fuel economy mandates. Reducing internal friction losses by even 1-2% translates to measurable MPG improvements across a manufacturer’s entire fleet. However, thinner fluids place greater demands on additive packages to maintain protection. This is why modern synthetic formulations are expensive—the base stock and additive chemistry required to protect transmissions with fluids that flow like water are significantly more sophisticated than traditional mineral-based ATF.

Critical Compatibility Warning: Never mix different specification families without verification. Combining DEXRON III with ATF+4, mixing CVT fluid with conventional ATF, or blending ultra-low viscosity fluid with regular ATF creates unpredictable friction characteristics and can cause immediate transmission problems. If you’ve added the wrong fluid by mistake, have the transmission completely drained and refilled with correct specification fluid immediately—before driving more than necessary to reach a service facility.

How to Check Transmission Fluid – Procedures and What to Look For

Traditional Dipstick Method

Most vehicles manufactured before 2010 and many newer models feature accessible transmission dipsticks, making fluid level checks relatively straightforward. However, the procedure requires precision—incorrect technique produces false readings that can lead to overfilling or underfilling, both potentially damaging.

Preparation is crucial. Park on level ground—even slight inclines cause false readings. Set the parking brake firmly. Start the engine and allow it to reach normal operating temperature. This typically requires 10-15 minutes of driving or 20 minutes of idling. Cold fluid gives inaccurate readings because ATF expands significantly with heat—a transmission that appears full when cold may actually be critically low at operating temperature.

With engine running and your foot firmly on the brake pedal, slowly shift through all gear positions: Park, Reverse, Neutral, Drive, and Low (if equipped), pausing 2-3 seconds in each position. This circulates fluid throughout the transmission, filling all passages, clutch packs, and the torque converter. Return to Park. On most vehicles, you check fluid level in Park with engine running. Honda is the notable exception—Honda specifies checking with engine OFF immediately after the warm-up drive. Consult your owner’s manual to verify the correct procedure for your specific vehicle.

Locate the transmission dipstick. On rear-wheel-drive vehicles, it’s typically toward the rear of the engine compartment on the passenger side, near the firewall. On front-wheel-drive vehicles, look near the driver’s side, often between the engine and the transmission. The transmission dipstick handle is usually colored red, pink, or yellow to distinguish it from the engine oil dipstick (typically black or yellow).

Remove the dipstick and wipe it completely clean with a lint-free cloth—even tiny particles of debris can contaminate the dipstick tube. Fully reinsert the dipstick until it seats completely. Immediately remove it again and observe the fluid level. Most dipsticks have separate markings for “Hot” and “Cold”—use the hot markings since you’ve warmed the transmission. Fluid level should fall between the “Add” and “Full” marks on the hot side. If it’s at or below “Add,” you need to add fluid.

Critical measurement note: The distance between “Add” and “Full” typically represents one quart of capacity. Adding too much fluid is as harmful as too little—overfilled transmissions develop pressure problems, accelerated seal leaks, and fluid foaming. Add small quantities (1/2 pint at a time), recheck level, and repeat until correct. Use a long, flexible funnel inserted into the dipstick tube for filling—most transmission dipstick tubes are 2-3 feet long with sharp bends.

If you need to determine what transmission you have before checking fluid specifications, our identification guide provides detailed procedures for various makes and models.

Sealed Transmissions Without Dipsticks

Modern automotive engineering increasingly eliminates owner-serviceable components, and transmission dipsticks are victims of this trend. Manufacturers promote “sealed for life” or “lifetime fluid” transmissions, claiming no maintenance is required. However, the definition of “lifetime” is ambiguous—it typically means “for the warranty period” or “under ideal conditions,” not the vehicle’s actual service life.

Check Plug Method: Some sealed transmissions have a fill plug with built-in overflow—when the plug is removed and fluid drips out, the level is correct. This requires raising the vehicle, working underneath while the engine runs, and achieving precise fluid temperature (often 85-95°F) for accurate checking. These procedures demand professional equipment and training.

Universal Transmission Dipstick Tools: Aftermarket flexible dipsticks are available for many makes and models, designed to insert through the fill tube port to measure level. These work for some applications but require knowing the exact correct insertion depth and interpreting manufacturer-specific markings. If you’re comfortable with this approach, verify compatibility with your specific transmission model.

Electronic Monitoring: Higher-end vehicles sometimes monitor transmission fluid level through internal sensors, displaying status through the dashboard information system or requiring scan tool access through the OBD-II port. These systems typically alert only to critically low levels, not gradual depletion or degradation.

Professional Service Recommendation: If your vehicle lacks an accessible dipstick, have transmission fluid level and condition checked by a qualified transmission shop every 30,000-50,000 miles as preventive maintenance. The inspection cost ($40-80) is negligible insurance against transmission failure, and technicians can identify developing problems before they become catastrophic.

Important Safety Warning: Checking sealed transmission fluid often requires vehicle lift, precise temperature control, and working with hot fluid under the vehicle. These procedures present significant burn risk and should only be performed by qualified technicians with proper equipment. Do not attempt to check or fill sealed transmissions without professional tools and training.

Assessing Fluid Condition

Knowing the fluid level is only half the equation—condition matters equally. Fresh ATF provides immediate visual indication of health, while degraded fluid reveals problems requiring attention.

Normal ATF Appearance: Bright red or pink, highly transparent (you should be able to read text through a sample in a clear container), sweet or slightly tart smell reminiscent of cherries or strawberries. The distinctive red dye serves functional purpose beyond aesthetics—it helps identify transmission fluid leaks versus engine oil or coolant leaks.

Caution Stage: Dark red or brown coloration, beginning to lose transparency, smell transitioning from sweet to neutral. At this stage, fluid is aging and should be changed soon, but the transmission likely hasn’t suffered damage yet. This is the ideal time for preventive service—before chemical additives are exhausted but after you’ve gotten reasonable service life from the fluid.

Replace Immediately: Dark brown or black, completely opaque, distinctly burnt odor—acrid smell similar to burnt coffee or tar. This indicates severe thermal stress and additive depletion. The transmission may still function, but continuing to operate on severely degraded fluid accelerates wear dramatically. At this stage, simply changing fluid may not resolve underlying problems if internal damage has occurred, but fresh fluid prevents additional deterioration.

Texture Assessment: Place a drop of fluid between thumb and forefinger, rub them together. Normal fluid feels slippery and smooth with no grit or particles. Gritty texture indicates clutch material contamination—tiny particles from worn friction surfaces circulating through the transmission. This is a serious warning sign suggesting significant internal wear.

Critical Contamination Indicators:

Metal particles (visible as shiny flakes or sparkles in the fluid) indicate severe internal component wear—bearings failing, gear teeth pitting, or hard parts breaking apart. This level of contamination suggests transmission damage that fluid changes alone won’t repair. Professional diagnosis is essential.

Milky appearance or foaming indicates coolant contamination, typically from a failed transmission cooler allowing coolant and ATF to mix. This is a critical emergency requiring immediate professional attention. Coolant destroys ATF’s lubricating properties and causes rapid internal damage. Do not drive the vehicle—have it towed to a transmission specialist.

For comparison with other vehicle fluid maintenance, see our guide on how to change oil, which covers similar inspection principles for engine lubrication.

Beginner Warning: If fluid appears burnt (dark brown/black) or contains metal particles, simply changing the fluid may not solve the underlying problem. At this stage, internal transmission damage may have already occurred. Professional diagnosis determines whether fresh fluid and continued operation is safe or whether internal repairs are necessary. Don’t assume a fluid change will fix transmission problems that have already produced symptoms—it’s preventive maintenance, not a repair procedure.

ATF Change Intervals – How Often Should You Change Transmission Fluid?

Manufacturer Recommendations vs. Real-World Practice

Official maintenance schedules vary wildly across makes, models, and even model years of the same vehicle. Some manufacturers specify 30,000-mile intervals for “severe service,” 60,000-100,000 miles for “normal service,” and increasingly, “lifetime fluid” requiring no changes whatsoever. Understanding what these recommendations actually mean—and what they don’t say—helps you make informed maintenance decisions.

The 30,000-60,000 Mile Traditional Standard: Older service recommendations typically called for transmission fluid changes every 30,000-60,000 miles depending on driving conditions. This interval originated when ATF formulations were less sophisticated and transmissions operated at higher temperatures due to less efficient cooling systems and lower gear counts requiring more frequent shifting. These recommendations still apply to vehicles manufactured before roughly 2010 using conventional mineral-based ATF.

The 60,000-100,000 Mile Modern Standard: Vehicles equipped with synthetic ATF and improved transmission designs often specify longer intervals, particularly under “normal” driving conditions. The synthetic base stocks and advanced additive packages in modern formulations maintain protective properties longer than older mineral fluids. However, this extended interval assumes truly normal operating conditions—not the “severe service” that describes most real-world driving.

The “Lifetime” Fluid Controversy: Increasingly, manufacturers claim transmission fluid is “sealed for life” and requires no service. This specification deserves careful scrutiny. When engineers say “lifetime,” they typically mean one of three things: (1) the warranty period (often 100,000 miles or less), (2) the expected service life under ideal conditions (perhaps 150,000-200,000 miles of gentle highway driving), or (3) the point at which transmission replacement becomes more economical than continued maintenance (essentially, until it fails).

Transmission repair specialists consistently report that “lifetime” fluids degrade significantly by 100,000 miles, showing darkening, viscosity changes, and additive depletion. They routinely see transmissions with “lifetime” fluid failing between 120,000-180,000 miles from fluid-related problems that preventive changes would have avoided. The industry consensus: “lifetime” is marketing language, not engineering reality.

The economic incentive is clear. Manufacturers want to minimize warranty claims within the warranty period while reducing the listed maintenance costs that appear in total cost of ownership comparisons. A transmission that fails at 130,000 miles—well outside warranty—due to degraded “lifetime” fluid represents no cost to the manufacturer but generates significant replacement transmission sales. Independent repair shops have no such incentive—they recommend fluid changes because they prevent the transmission failures they repair daily.

Severe Service vs. Normal Service Definitions

Understanding which category describes your driving determines appropriate maintenance intervals. Most drivers assume they operate under “normal” conditions, but manufacturer definitions of “severe service” encompass the majority of real-world use.

Severe Service Conditions (recommend fluid change every 30,000-50,000 miles):

- Frequent towing or hauling: Any regular towing—even small trailers within rated capacity—qualifies. Towing increases transmission torque loads and generates significant heat, accelerating fluid degradation.

- Stop-and-go traffic: Daily commuting in urban traffic with frequent speed changes means constant shifting, heat generation, and torque converter operation without lockup—all stressing the fluid. Commuting 10 miles through city traffic is more severe than highway cruising 50 miles.

- Short trips: Trips under 10 miles, particularly in cold weather, don’t allow the transmission to reach optimal operating temperature. This prevents moisture evaporation from the fluid and accelerates acid formation from condensation.

- Extreme temperatures: Operating in very hot climates (Southwest U.S., southern states in summer) or extreme cold (northern states, Canada, Alaska) stresses fluid thermal properties. Heat accelerates oxidation; cold increases viscosity and mechanical stress during warm-up.

- Mountain driving: Sustained steep grades—either climbing or descending with aggressive engine braking—generate significant heat through increased torque loads and converter slip.

- Commercial or fleet use: Taxi service, delivery routes, police patrol, or any commercial application involves extended idling, frequent starts/stops, and sustained operation—all severe conditions.

- Off-road or dusty conditions: Contamination potential increases in these environments despite sealed transmission cases. Dust intrusion through breather vents and accelerated differential seal wear (in all-wheel-drive vehicles) can contaminate transmission fluid.

Normal Service: Primarily highway driving at steady speeds, moderate temperatures, no towing, minimal stop-and-go operation, longer trips allowing full warm-up. This describes very few actual drivers—perhaps retirees who take occasional highway trips, rural drivers with mostly open-road commutes, or dedicated highway vehicles.

Professional Reality Check: If you’re unsure which category applies, assume severe service. The cost difference between 30,000-mile and 60,000-mile intervals—perhaps one or two additional services over 150,000 miles—is trivial compared to transmission replacement or rebuild costs. Transmission specialists consistently report that vehicles serviced on shorter intervals experience significantly fewer failures than those following extended “normal service” intervals.

Even for vehicles with “lifetime” fluid specifications, consider at least one fluid service around 100,000 miles if you intend long-term ownership. The $150-400 service cost provides insurance against the $3,000-6,000 transmission replacement that often occurs between 120,000-180,000 miles when original fluid is never changed.

For maintenance planning across your vehicle’s systems, see our discussion of how long oil changes take, which addresses scheduling preventive maintenance for busy lifestyles.

The High-Mileage First-Service Controversy

Among transmission specialists, few topics generate more debate than whether to change fluid in high-mileage transmissions that have never had service. The concern stems from documented cases where transmissions failed shortly after their first fluid change at 100,000+ miles, leading some mechanics to advise against late-life service.

The Theory Behind the Concern: Fresh ATF contains full-strength detergent additives designed to clean varnish and deposits. In a transmission that’s operated for 100,000+ miles on original fluid, significant varnish buildup may have accumulated on valve body passages, clutch pack surfaces, and internal components. When fresh detergent-loaded fluid enters the system, it can dislodge this material in large quantities, potentially plugging filters, contaminating solenoids, or causing pressure control problems. Additionally, worn clutch packs may have adapted to degraded fluid’s friction characteristics—fresh fluid with different friction properties might cause those worn components to slip.

The Reality: Documented failures after high-mileage fluid changes typically involve one or more of these factors:

- Pre-existing internal problems: The transmission already had worn clutches, damaged seals, or failing components. These problems were masked by degraded fluid’s reduced cleaning action. Fresh fluid simply revealed existing damage rather than causing it.

- Aggressive flush rather than drain-and-fill: High-pressure machine flushing forcibly circulates fluid throughout the transmission, potentially dislodging more material than gentle drain-and-fill. The forceful circulation increases risk of debris contamination.

- Incorrect fluid specification: Using wrong ATF type causes friction characteristic changes that worn clutches can’t tolerate. This isn’t a “high-mileage” issue—it’s simply wrong fluid causing problems.

- Overfilling: Adding too much fluid during service creates pressure problems and foaming that damages seals and causes erratic shifting.

Evidence-Based Approach: The preponderance of evidence suggests that properly executed fluid changes—even at high mileage—more often extend transmission life than cause problems. Transmissions are designed to operate with clean fluid; degraded fluid accelerates wear regardless of mileage. The risk comes not from changing fluid but from how the change is performed and what underlying condition the transmission is in when serviced.

Best Practices for High-Mileage First Service:

If your transmission shifts smoothly with no symptoms (slipping, harsh shifts, delayed engagement), fluid change is generally safe and beneficial. A properly functioning transmission at 100,000 miles isn’t damaged by fresh fluid—it’s protected by it.

Use the drain-and-fill method rather than power flush. Draining the pan removes 40-60% of fluid capacity in a gentler process that doesn’t force material through the system under pressure.

Consider a series of drain-and-fills spaced 1,000-2,000 miles apart. This gradually refreshes the fluid, allowing detergents to work progressively rather than shocking the system with 100% fresh fluid immediately.

Always use the exact fluid specification in your owner’s manual. This is critical at any mileage but especially important in high-mileage transmissions where worn components have adapted to specific friction characteristics.

Replace the filter during the service if your transmission has an accessible external filter. Many internal filters aren’t replaceable without major disassembly, but external filters should always be changed during fluid service.

If the transmission already exhibits symptoms (slipping, harsh shifts, delayed engagement, strange noises), fluid change alone probably won’t resolve the problems because internal damage has likely occurred. However, fresh fluid prevents additional deterioration and buys time to save for repair or replacement. At this stage, the transmission is already compromised—proper fluid service won’t make it worse and might extend its remaining life.

Regional Considerations and Operating Conditions

Climate and geography significantly affect optimal ATF service intervals. The 60,000-mile “normal service” recommendation assumes moderate temperatures and relatively flat terrain—conditions that don’t match much of North America.

Hot Climate Operation (Southwest U.S., Southern states, desert regions): Ambient temperatures routinely exceeding 90°F push transmission operating temperatures higher. When outside air is 105°F, the transmission cooler has less temperature differential to dissipate heat, meaning internal temperatures climb toward 250°F or beyond during summer driving. At these elevated temperatures, oxidation reactions accelerate exponentially—fluid that would last 60,000 miles in temperate climates degrades in 30,000-40,000 miles in extreme heat.

Consider adding a supplemental transmission cooler if you regularly drive in very hot climates, tow, or both. The investment ($200-400 installed) pays back quickly through extended transmission life and improved reliability. Combined with 30,000-40,000 mile fluid service intervals, supplemental cooling practically eliminates heat-related transmission failures.

Cold Climate Operation (Northern states, Canada, Alaska, mountain states): Extreme cold presents different challenges. At temperatures below 0°F, even synthetic ATF thickens significantly, making initial startup and the warm-up period stressful on transmission components. Cold fluid doesn’t flow easily through narrow passages, causing delayed shifts and inadequate lubrication until the transmission reaches operating temperature—typically 5-10 minutes of driving even in moderately cold weather, longer in extreme conditions.

Using manufacturer-specified synthetic ATF with superior cold-flow properties helps but doesn’t eliminate the issue. Allow extra warm-up time before aggressive driving in freezing conditions. Consider remote-start systems that warm both engine and transmission before driving. Fluid changes remain important in cold climates because moisture contamination from condensation accumulates in transmissions that frequently operate below normal temperature.

Mountainous Terrain: Sustained steep grades—common in Appalachian, Rocky Mountain, Sierra Nevada, and Cascade regions—generate extreme heat through high torque loads. Climbing steep grades at wide-open throttle pushes torque converter slip to maximum, producing tremendous heat. Descending long grades using engine braking for speed control also generates heat as the transmission absorbs vehicle momentum. Mountain driving definitely qualifies as severe service; 30,000-40,000 mile intervals are appropriate.

Towing and Payload: If you regularly tow trailers or carry heavy cargo near your vehicle’s payload capacity, this is severe service regardless of climate or terrain. The additional load increases torque multiplication demand, converter heat generation, and cooling system stress. Professional towing operators often service transmissions every 15,000-25,000 miles because heat and load accelerate fluid degradation dramatically.

Warning Signs Your Transmission Fluid Needs Attention

Recognizing Problem Symptoms Early

Transmissions rarely fail without warning—they typically develop progressive symptoms that begin subtly and worsen over time. Recognizing these early indicators and responding with appropriate service often prevents minor issues from becoming major repairs. Understanding what each symptom indicates helps you assess urgency and decide whether DIY diagnosis is appropriate or professional attention is required immediately.

Delayed Gear Engagement manifests as a noticeable 2-3 second pause when shifting from Park into Drive or Reverse. You move the shifter, but the transmission doesn’t engage immediately—there’s dead time before you feel the characteristic “clunk” of engagement. This delay indicates insufficient hydraulic pressure to rapidly fill and clamp the clutch packs. Low fluid level is the most common cause, but degraded fluid with reduced viscosity can also prevent rapid pressure buildup. Check fluid level immediately—if it’s low, you have a leak that needs diagnosis even after you top off the fluid. If level is correct but fluid is dark and burnt-smelling, the fluid has degraded and requires service.

Delayed engagement when cold but normal when warm suggests fluid viscosity issues—the fluid is too thick when cold to flow rapidly through passages. This can indicate wrong fluid specification, severely degraded fluid, or moisture contamination causing viscosity changes. If engagement timing is normal when cold but delays increase as transmission warms, this is less common but more serious—it suggests internal seal wear allowing hot pressure to leak faster than the pump can sustain it.

Transmission Slipping or “Gear Hunting” presents as engine RPM increasing without corresponding vehicle speed increase. You press the accelerator, the tachometer climbs, but acceleration is sluggish or nonexistent—the engine is revving but power isn’t reaching the wheels. Alternatively, the transmission may “hunt” between gears—shifting up, then immediately back down, then up again—unable to find and hold the correct gear ratio. Both conditions indicate the clutch packs aren’t staying fully clamped together, allowing slip between input and output shafts.

Low fluid level is an immediate suspect—insufficient fluid means inadequate pressure to keep clutches locked. However, slipping can also result from:

- Severely worn clutch friction material that can’t grip even when fully compressed

- Internal seal failure allowing pressure to leak from clutch apply circuits

- Contaminated fluid that’s changed friction characteristics—either too slippery (from wrong fluid type) or too aggressive (from clutch material particles acting as abrasive)

- Failed solenoids or valve body problems preventing proper pressure control

If your vehicle experiences slipping, check fluid level immediately. If level is correct and fluid appears normal, professional diagnosis is essential—continuing to drive a slipping transmission causes rapid damage as overheating metal surfaces wear exponentially faster than properly engaged clutches.

Harsh, Jerky, or Clunking Shifts represent the opposite problem. Instead of smooth, barely noticeable gear changes, shifts feel like you’ve driven over a speed bump—passengers notice, drinks spill, and there may be audible clunking sounds accompanying each shift. This indicates clutches are engaging too aggressively rather than gradually ramping up pressure.

Friction modifier depletion in old fluid is a common cause—as these additives exhaust, clutch surfaces transition from smooth engagement to grab-and-release behavior. Contamination from clutch material particles can create the same effect. Wrong fluid specification is another possibility—fluid without appropriate friction modifiers (like using Type F in a transmission requiring DEXRON) produces harsh shifts intentionally in some applications but problematically in others.

Internal problems can also cause harsh shifts—sticking valve body components, failed pressure control solenoids, or internal seal damage. However, fluid-related causes are more common and should be addressed first through proper service before assuming mechanical failure.

Unusual Transmission Noises provide specific diagnostic information depending on the sound characteristics:

Whining or humming that varies with vehicle speed typically indicates low fluid level causing transmission pump cavitation. The pump is drawing air along with fluid, creating noise as air bubbles collapse under pressure. This is serious—cavitation damages pump components and creates aerated fluid that doesn’t transmit pressure effectively. Check fluid level immediately.

Grinding or clicking sounds especially during shifts suggest metal-to-metal contact—possibly worn synchronizers (in manual transmissions), damaged gear teeth, or bearing failure. Metal particles circulating in fluid can also create grinding or buzzing sounds as they pass through narrow clearances. If you hear grinding, stop driving and have the vehicle towed for professional diagnosis—continuing to operate a transmission with mechanical damage causes catastrophic failure.

Buzzing or vibration at specific speeds often indicates torque converter problems. The converter may have damaged internal components or imbalanced components that create vibration as fluid circulates at certain speeds. This can be fluid-related if wrong specification has changed converter clutch engagement characteristics, but more often indicates mechanical problems within the converter itself.

Burning Smell from the transmission area is never normal and always indicates serious overheating. ATF heated beyond roughly 240°F begins thermal breakdown, producing a distinctive acrid smell—different from engine oil burning, less “oily” and more sharp and chemical. This odor indicates the transmission is experiencing severe stress from:

- Low fluid level causing inadequate cooling

- Sustained towing or heavy load operation exceeding the transmission’s cooling capacity

- Internal slipping from worn clutches generating excessive friction heat

- Blocked transmission cooler preventing heat dissipation

If you smell burning transmission fluid, stop driving as soon as safely possible. Check fluid level—if it’s significantly low, have the vehicle towed rather than driving to add fluid. Operating a severely overheated transmission for even short distances causes damage that progresses from fluid degradation to internal component failure rapidly. The smell indicates the fluid is already breaking down—continued operation accelerates the destruction.

Check Engine Light with Transmission-Related Codes appears on modern vehicles with sophisticated transmission monitoring. The powertrain control module continuously monitors transmission operation through sensors measuring input speed, output speed, fluid temperature, line pressure, and individual solenoid function. When readings fall outside expected parameters, diagnostic trouble codes (DTCs) are stored and the check engine light illuminates.

Common transmission-related DTCs include:

- P0868: Transmission fluid pressure low

- P0711-P0713: Transmission fluid temperature sensor problems (may indicate actual overheating or sensor failure)

- P0715-P0717: Input shaft speed sensor problems (can indicate slipping if actual speed differs from expected)

- P0731-P0734: Incorrect gear ratio (indicates slipping or mechanical problems)

Have DTCs read by auto parts store (usually free) or using personal scan tool. Transmission-related codes may indicate fluid-level problems, temperature issues, or early-stage mechanical failures that aren’t yet producing noticeable driving symptoms. Addressing these warnings early prevents progression to severe failure.

Visible Fluid Leaks appear as red or dark brown puddles under your vehicle, typically near the transmission area midway along the vehicle centerline. Common leak points include:

- Transmission pan gasket (leaks from the bottom)

- Output shaft seals (leaks from front or rear of transmission where it connects to driveshaft or axles)

- Transmission cooler lines (leaks from rubber hoses or hard lines running to radiator)

- Torque converter seal (leaks from between engine and transmission)

- Dipstick tube seal (leaks from dipstick tube mounting point)

Even small leaks require attention because they lead to low fluid level. A transmission that appears full today but loses fluid gradually will run low between checks, potentially causing damage before you notice. Address leaks promptly—repair costs for external seal replacement ($200-600 depending on location and complexity) are modest compared to internal transmission damage from operating with low fluid.

Understanding how other hydraulic systems like ABS operate helps contextualize the importance of maintaining proper ATF levels and condition.

Emergency Situations Requiring Immediate Professional Attention

Certain symptoms indicate transmission failure is imminent or already occurring. These situations require immediate professional diagnosis and likely major repair—not DIY fluid service or “wait and see” approaches.

Complete Loss of Drive or Reverse (vehicle won’t move in one or more gears) indicates catastrophic internal failure—complete clutch pack failure, broken internal components, or total loss of hydraulic pressure. This is a tow-only situation. Even if you can move in some gears, don’t attempt to drive to a repair facility—operating a severely damaged transmission worsens damage and increases repair costs.

Milky Fluid Appearance indicates coolant contamination from failed transmission cooler. Most vehicles use an internal transmission cooler inside the engine radiator, with ATF and engine coolant separated only by thin metal passages. When these passages corrode or crack, coolant mixes with ATF, creating a milky pink or brown fluid. This is catastrophic contamination—coolant destroys ATF’s lubricating properties and causes rapid internal damage. The transmission must be completely drained, flushed multiple times, and refilled with fresh fluid. Often, internal components are already damaged from operating with contaminated fluid. This is a tow-immediately situation requiring professional service.

Metal Shavings in Fluid (visible sparkly particles) indicate severe internal wear—bearings disintegrating, gear teeth pitting, or hard parts breaking up. At this stage, fluid changes alone won’t repair the damage because metal contamination has likely already scored bearing surfaces, damaged solenoids, and accelerated wear throughout the system. Professional diagnosis determines whether rebuild is feasible or replacement is necessary.

Sudden Dramatic Behavior Change After Service (transmission worked fine before fluid service, exhibits severe problems immediately after) suggests wrong fluid specification was used, severely damaged filter was disturbed during service, or air entered the system during improper filling procedure. Return to the facility that performed service immediately—responsible shops will drain and refill with correct fluid or diagnose what went wrong during their service.

Smoke from Transmission Area (visible smoke, not just smell) indicates active overheating with fluid temperature likely exceeding 300°F. At these temperatures, seals melt, internal components warp, and catastrophic failure is imminent. Pull over immediately, shut off the engine, and have the vehicle towed. Do not attempt to diagnose or repair roadside—transmission fires, while rare, are possible at extreme temperatures.

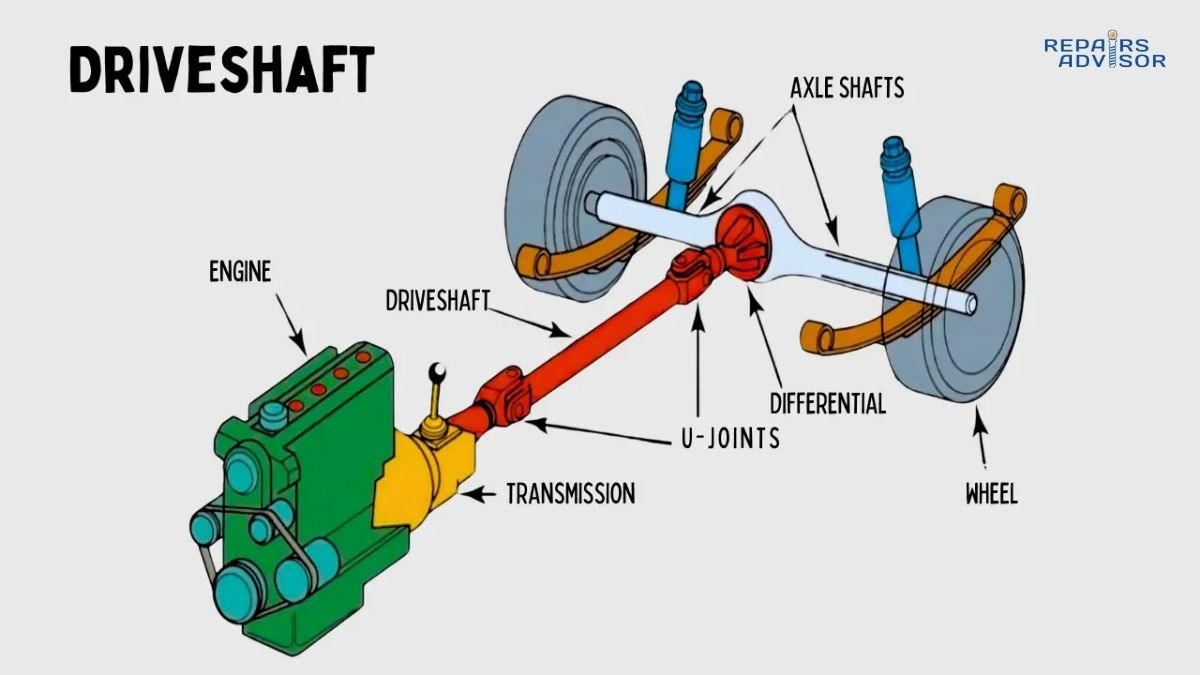

Understanding fluid behavior in the related differential systems provides broader context for drivetrain maintenance requirements.

Safety Critical Warning: Transmission problems that occur while driving—sudden gear loss, violent shifting, or complete power loss—are dangerous beyond the mechanical damage. Loss of power during highway merging, unexpected shifting during cornering, or vehicle suddenly slowing can cause accidents. If your transmission exhibits severe symptoms, avoid highway driving, merge situations, and busy traffic. Have the vehicle towed rather than attempting to “make it home”—the increased repair cost from additional driving damage often exceeds towing charges, and the safety risk isn’t acceptable.

Transmission Fluid Service Methods – Drain and Fill vs. Flush

Understanding the differences between drain-and-fill and flush procedures helps you make informed service decisions and communicate effectively with service providers. Both methods replace transmission fluid but accomplish this through fundamentally different processes with distinct advantages and disadvantages.

Drain-and-Fill Service Explained

The drain-and-fill method represents traditional transmission service procedure that’s been standard practice for decades. The process involves raising the vehicle, removing the transmission pan (typically held by 12-20 bolts), allowing fluid to drain by gravity, replacing the filter if accessible, reinstalling the pan with new gasket or RTV sealant, and refilling with fresh fluid through the dipstick tube or fill plug.

Advantages of Drain-and-Fill:

Gentler on the transmission because it doesn’t force fluid through the system under pressure. Old fluid drains by gravity; new fluid is added and circulates naturally as the transmission operates. This reduces risk of dislodging large chunks of accumulated debris that could plug passages or damage components.

Allows pan inspection which provides valuable diagnostic information. When the pan is removed, you can examine residue and debris collected at the bottom. Normal service shows fine metallic dust (normal wear) and some dark residue (captured by filter). Excessive metal particles, chunks of friction material, or large metallic pieces indicate internal problems requiring professional attention beyond fluid service.

Replaces filter simultaneously in transmissions with accessible external filters. Not all transmissions have serviceable filters—many modern units use internal filters that require major disassembly to access—but when present, filter replacement is critical. A clogged filter restricts fluid flow, reduces pressure, and accelerates wear.

Lower cost reflects simpler procedure and less specialized equipment. Typical drain-and-fill service costs $150-250 depending on labor rates, pan gasket cost, filter cost, and fluid quantity. This is owner-friendly maintenance that most independent shops and dealerships perform routinely.

Recommended for high-mileage first-time service because the gradual, non-pressurized approach minimizes risk when servicing neglected transmissions. If you’re changing fluid for the first time at 100,000+ miles, drain-and-fill is the safer approach.

Disadvantages of Drain-and-Fill:

Only replaces 40-60% of total fluid capacity because fluid remains in the torque converter, valve body passages, cooler, and cooler lines. A transmission with 12-quart capacity may only drain 5-7 quarts during pan removal. The new fluid you add mixes with remaining old fluid, diluting but not completely replacing it.

May require multiple services spaced 1,000-2,000 miles apart to fully refresh fluid. If the goal is complete fluid replacement, sequential drain-and-fills accomplish this through gradual dilution. First service replaces 50%; second service (after short interval allowing mixing) replaces another 50% of the remaining old fluid (leaving 25% original), third service reduces to 12.5% original, and so on.

Doesn’t clean cooler or torque converter because fluid in these components never drains. Any debris, sludge, or varnish in the cooler lines or torque converter remains after drain-and-fill service.

Transmission Flush Procedure and Considerations

Transmission flush uses specialized equipment that connects to the transmission cooler lines, forcing new fluid through the system under pressure while simultaneously extracting old fluid. The machine circulates fluid in one direction while extracting from the other, achieving nearly 100% fluid replacement in a single operation lasting 30-60 minutes.

Advantages of Flush:

Replaces virtually all fluid including what remains in torque converter, valve body, and cooler lines. This achieves complete fluid renewal in one service rather than requiring multiple drain-and-fills.

Flushes contaminants from cooler system by forcing fresh fluid through cooler lines and radiator passages, potentially removing accumulated debris that restricts flow.

More thorough internal cleaning as pressurized fluid circulation reaches all passages and may dissolve or suspend varnish deposits.

Time-efficient for the shop—one hour of machine operation versus the labor-intensive process of raising vehicle, removing pan, replacing filter, and reinstalling pan.

Disadvantages and Concerns:

More expensive typically $200-400 due to machine costs, longer service time, and larger fluid quantity. The price premium over drain-and-fill is significant for a service that may not be necessary for well-maintained transmissions.

Potentially aggressive for high-mileage transmissions because pressurized fluid circulation can dislodge substantial accumulations of varnish or debris, potentially creating contamination problems worse than original fluid’s condition. This is the primary objection from transmission specialists who see failures shortly after flush service.

Doesn’t allow pan inspection or filter replacement unless these are performed as separate procedures. Many flush-only services skip these steps, meaning you don’t get diagnostic information from pan inspection and the old filter remains in place to catch debris dislodged by the flush—potentially clogging the filter and causing pressure problems.

Risk of improper procedure if the shop uses poor-quality equipment, wrong fluid specification, or doesn’t follow manufacturer-specific procedures. Reputable shops with modern equipment perform excellent work; budget facilities cutting corners can cause problems.

Professional Perspective: Transmission specialists are divided on flush services. Some embrace modern flush equipment as superior to drain-and-fill when properly executed. Others refuse to perform flushes on high-mileage transmissions, citing documented failures shortly after service. The consensus middle ground: flush works well for properly maintained transmissions on regular service intervals (30,000-60,000 miles) but drain-and-fill is safer for high-mileage first-time service or neglected transmissions.

If you choose flush service, ensure the shop:

- Uses manufacturer-specified fluid (not universal fluid unless verified compatible)

- Has modern flush equipment with adjustable pressure control

- Includes pan drop and filter replacement as part of the service

- Provides before/after fluid samples so you can verify old fluid was actually contaminated enough to justify the service

Understanding the differences in service methods for brake fluid provides useful comparison for hydraulic system maintenance across your vehicle.

Choosing the Appropriate Service Method

For regular maintenance on well-maintained vehicles (fluid changed every 30,000-60,000 miles), either method works fine. Choose based on cost, shop recommendation, and personal preference.

For first-time service on high-mileage vehicles (100,000+ miles, never serviced), drain-and-fill is the safer choice. The gentler approach minimizes risk while still providing substantial fluid renewal.

For severely neglected transmissions (dark, burnt fluid; symptoms present), drain-and-fill is mandatory. These transmissions need careful evaluation during pan removal to assess internal condition before deciding on further service.

For transmission showing symptoms (slipping, harsh shifts, strange noises), drain-and-fill with pan inspection is diagnostic as well as service. The pan contents reveal whether internal problems exist beyond fluid degradation.

Cost-conscious approach: Multiple drain-and-fills spaced over time cost more in total service charges but less per service. Budget-friendly option performs first drain-and-fill, drives 2,000 miles, performs second drain-and-fill, achieving nearly complete fluid renewal across two less-expensive services.

Convenience approach: Single flush service achieves complete fluid renewal immediately with less downtime, despite higher cost. Choose this for time-sensitive situations or when the transmission is properly maintained and you want thorough service in one visit.

DIY vs. Professional Service – Safety and Practical Considerations

When DIY Service Is Appropriate

Transmission fluid maintenance falls into that challenging middle ground—more complex than oil changes but less demanding than major mechanical repairs. Confident intermediate DIY mechanics with appropriate equipment can successfully perform drain-and-fill service on many vehicles, achieving significant cost savings while maintaining their transmissions properly.

DIY Candidates:

Checking fluid level and condition on dipstick-equipped transmissions is straightforward and should be part of every vehicle owner’s basic maintenance routine. The procedure requires no tools beyond clean rags, takes 10 minutes, and provides critical diagnostic information. Even if you prefer professional service for actual fluid changes, knowing how to check fluid level and recognize degradation is valuable.

Drain-and-fill service on pan-accessible transmissions is within reach for mechanically inclined owners with proper equipment. Vehicles with external filters that mount to the transmission case or inside the pan are most DIY-friendly. The procedure requires lifting the vehicle safely, basic hand tools, torque wrench, and clean workspace but doesn’t demand specialized equipment or extensive mechanical knowledge.

Topping off fluid when level is slightly low (assuming correct fluid type is verified) is simple maintenance that prevents damage from gradual losses. However, always identify and repair the source of fluid loss—transmissions shouldn’t consume fluid, so low level indicates a leak requiring attention even after topping off.

Required Equipment and Skills:

- Hydraulic floor jack and quality jack stands rated for your vehicle’s weight, or drive-on ramps (never rely solely on floor jack—use jack stands or ramps)

- Large drain pan with minimum 8-quart capacity (preferably 10-12 quarts to contain all draining fluid without overflow)

- Socket set, wrenches, and torque wrench capable of 12-25 ft-lbs (typical pan bolt torque range)

- Clean workspace with adequate lighting and ventilation

- Long flexible funnel or fluid pump for adding fluid through dipstick tube (often 2-3 feet of narrow tube with sharp bends)

- Pan gasket or RTV sealant as specified for your transmission (verify correct type—some use cork gaskets, others require rubber gaskets or RTV)

- Transmission filter (if your model has serviceable external filter)

- Correct ATF specification verified from owner’s manual (never assume—wrong fluid causes immediate problems)

Skill requirements: Basic mechanical aptitude, comfort working under raised vehicle, ability to follow torque specifications precisely, attention to cleanliness (even tiny particles contaminate transmission), patience for methodical work.

Cost Savings: Significant—DIY drain-and-fill typically costs $50-80 in parts and fluid compared to $150-250 professional service. Over vehicle ownership, performing this service yourself every 50,000 miles saves $300-600 while learning valuable mechanical skills.

For context on other routine maintenance procedures, our guide on how to change oil provides similar DIY considerations for engine maintenance.

When Professional Service Is Essential

Despite potential cost savings, many transmission service scenarios demand professional expertise and equipment. Attempting these procedures yourself risks expensive damage, personal injury, or creating problems worse than the original issue.

Always Use Professional Service For:

Sealed transmissions without accessible drain plug or dipstick require specialized tools, technical manuals specifying exact fill quantities and procedures, and often scan tools to verify proper fluid level at specific operating temperatures. These are not DIY procedures—professional shops have the equipment and training to service these transmissions safely.

CVT or DCT transmissions are extremely sensitive to incorrect fluid or improper procedure. CVT fluid level is particularly critical—overfilling by even half a quart can cause belt slippage and catastrophic failure. DCT clutch pack bleeding procedures require specific equipment and expertise. The cost of errors with these transmissions is prohibitive—always use professionals who have experience with your specific transmission type.

Any vehicle under warranty should receive only professional service at authorized facilities. DIY transmission service often voids transmission warranty, leaving you responsible for failure costs that would otherwise be covered. The warranty coverage value far exceeds service cost savings.

Transmission flush procedures require specialized equipment you won’t own as individual. Attempting to “flush” transmission by other methods (repeatedly drain-and-filling with engine running, for example) doesn’t achieve the same results and can introduce air into the system.

Transmissions already showing symptoms need professional diagnosis before any service. If your transmission slips, shifts harshly, makes unusual noises, or exhibits delayed engagement, fluid service alone may not resolve these issues. Professional inspection determines whether fluid service is appropriate or whether internal repairs are necessary first.

Fluid level checks on sealed transmissions typically require raising the vehicle, achieving specific fluid temperature (often monitored via scan tool), and working with hot fluid under the vehicle. These procedures present significant burn risk and should only be performed by professionals with proper equipment.

Understanding why other complex systems like electronic power steering require professional service provides context for these recommendations.

Critical Safety Precautions

Working with Hot Fluid: Transmission fluid operates at 180-220°F—well above the 160°F threshold for immediate severe burns. Always allow adequate cooling time before removing the pan or drain plug. Even after the engine has been off for 30 minutes, residual heat keeps fluid dangerously hot. Wear safety glasses and gloves—hot fluid can spray from drain plugs under pressure.

Vehicle Support: Transmission pan removal requires vehicle elevation. Use hydraulic floor jack and quality jack stands rated for your vehicle’s weight, positioned on specified lift points. Test stability before working under the vehicle—shake it vigorously to ensure it won’t shift. Never rely solely on a floor jack, bumper jack, or blocks—these are unstable and have caused numerous crushing fatalities.

Environmental Responsibility: Used ATF is hazardous waste containing toxic additives and petroleum compounds. Never pour it down drains, onto the ground, or into trash. Most auto parts stores, oil change facilities, and municipal hazardous waste facilities accept used ATF for proper disposal. Collect in sealed containers and transport carefully to prevent spills.

Skin Contact: ATF contains additives that can cause skin irritation with prolonged exposure. Wear chemical-resistant gloves (nitrile or similar). If fluid contacts skin, wash immediately with soap and water. Avoid breathing vapors—work in well-ventilated areas.

Prevent Contamination: Cleanliness is critical. Even small amounts of dirt, debris, or incorrect fluid contaminate the system. Use clean tools, work in clean area, keep caps on fluid containers until immediately before use. If you accidentally drop the pan or spill fluid, clean thoroughly before continuing—one tablespoon of dirt can cause valve body problems.

Fire Hazard: Although ATF has high flash point (typically 380-450°F) compared to gasoline, it is flammable at extreme temperatures. Keep hot exhaust components, welding equipment, and open flames away from fluid and fumes. Have fire extinguisher accessible when working.

First-Time Service Recommendation: If you’ve never performed transmission service, consider observing a professional perform the service while you learn the procedure. Many independent shops will allow you to watch and ask questions for the cost of the service. This hands-on education is invaluable before attempting the procedure yourself. Alternatively, have a professional perform the first service, pay careful attention to the process, and attempt DIY service at the next interval once you understand what’s involved.

Conclusion: Protecting Your Transmission Investment

Automatic transmission fluid represents one of the most sophisticated lubricants in your vehicle, simultaneously performing four critical functions that keep your transmission shifting smoothly and lasting beyond 200,000 miles. Understanding ATF specifications—from DEXRON and MERCON to manufacturer-specific formulations—isn’t just technical detail; it’s essential knowledge because using incorrect fluid causes damage within thousands of miles and potentially voids your warranty.

The evolution from universal fluids to vehicle-specific formulations reflects the increasing sophistication of modern transmissions. Today’s 8-speed, 9-speed, and 10-speed automatics, along with CVTs and DCTs, demand precise friction characteristics, specific viscosity grades, and particular thermal properties. The days when “any transmission fluid will work” are long gone—always verify your exact specification in the owner’s manual, confirm with your dealership if uncertain, and never substitute based on assumptions or what’s on sale at the parts store.

Regular maintenance is the single most effective method for preventing expensive transmission repairs. While manufacturers increasingly promote “lifetime” fluid, real-world evidence from transmission specialists is overwhelming: regular fluid changes every 50,000-60,000 miles for well-maintained vehicles, or 30,000-40,000 miles under severe service conditions, dramatically extend transmission life. The typical $150-400 cost of proper service is insignificant compared to $3,000-6,000+ for transmission rebuild or replacement.

Recognizing warning signs early—delayed engagement, harsh shifts, slipping, unusual noises, burning smells—allows you to address problems while they’re still minor. Many transmission issues that seem severe are actually fluid-related and resolve with proper service when caught early. Ignoring symptoms allows minor problems to progress to catastrophic failure that no amount of fresh fluid can repair.

Whether you perform drain-and-fill service yourself or rely on professional maintenance, using correct fluid specification and following proper procedures is non-negotiable. For high-mileage vehicles receiving first-time service, the drain-and-fill approach is safer than aggressive flushing. For well-maintained transmissions on regular intervals, either method works when properly executed. Always insist on correct fluid specification, replace the filter when accessible, and inspect the pan contents for diagnostic information about internal transmission condition.

When Professional Consultation Is Needed: If your transmission exhibits severe symptoms—complete gear loss, milky fluid appearance indicating coolant contamination, metal shavings in the fluid, or sudden dramatic behavior changes—professional diagnosis is essential before any service. At this stage, internal damage may already exist, and fluid changes alone may not resolve the problems. Qualified transmission specialists can determine whether your transmission needs simple fluid service, internal repairs, or complete rebuild/replacement. Ignoring severe symptoms or attempting DIY repairs on seriously damaged transmissions typically worsens the problem and increases eventual repair costs.

Understanding related drivetrain components like how planetary gearsets and valve bodies work or how the flywheel and flexplate connect your engine to transmission provides broader context for why proper ATF maintenance is so critical. The transmission is a precision mechanical device with tight tolerances and sophisticated electronic control—it deserves the same maintenance attention you give your engine.

The choice between DIY and professional service depends on your mechanical skills, available equipment, and transmission complexity. Simple fluid level checks and drain-and-fill services on accessible transmissions are reasonable DIY projects for mechanically inclined owners. Sealed transmissions, CVTs, DCTs, or transmissions already showing symptoms should always receive professional service from technicians with proper equipment and training.

Your transmission is one of your vehicle’s most expensive and critical components. Proper fluid maintenance—using correct specifications, following appropriate intervals, and responding promptly to warning signs—provides the best insurance against premature failure and ensures smooth, reliable operation for the life of your vehicle. The relatively modest investment in regular ATF service pays returns many times over through extended transmission life, maintained resale value, and avoided roadside breakdowns. Take transmission fluid maintenance seriously, and your transmission will reward you with hundreds of thousands of miles of trouble-free operation.

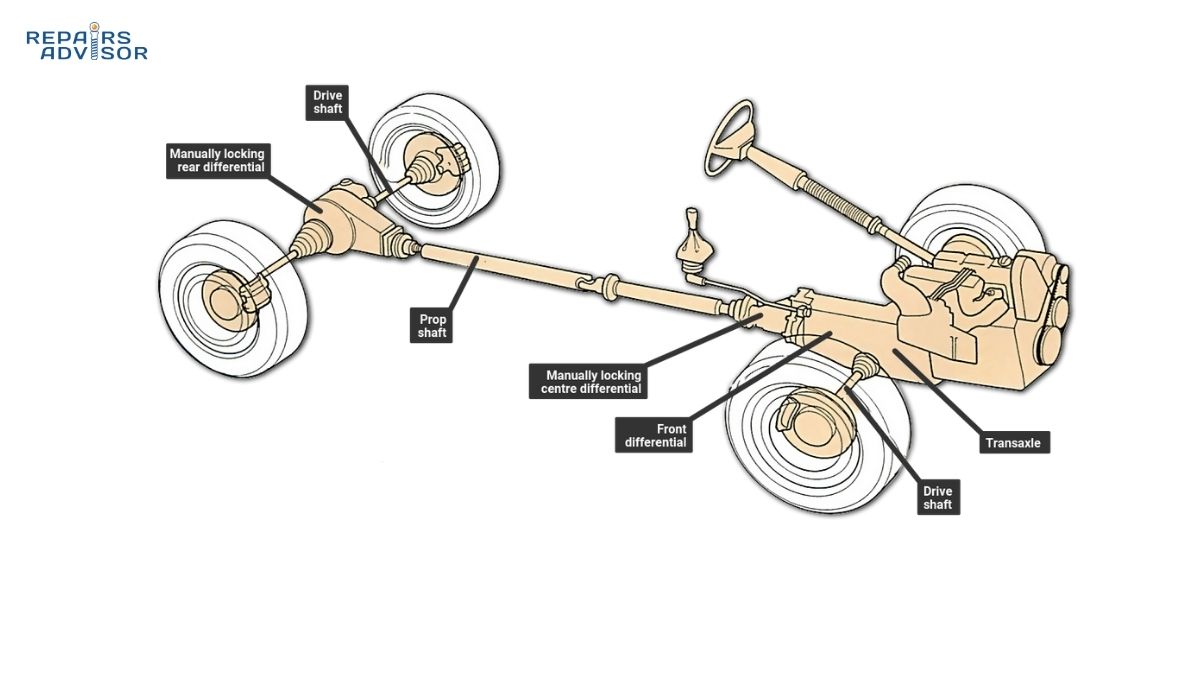

For additional maintenance context on related vehicle systems, explore our guides on single-speed EV transmissions for comparison with traditional automatic lubrication, or differential systems for understanding drivetrain fluid requirements across your vehicle’s power transfer components.