Picture this: you’re taking a highway exit ramp a bit faster than usual, and you feel your vehicle leaning heavily to one side. That unsettling sensation of body roll isn’t just uncomfortable—it’s reducing your tire contact with the road and compromising your vehicle’s stability. Enter the anti-roll bar, a deceptively simple component that plays a crucial role in keeping your vehicle planted and predictable through corners.

An anti-roll bar (also called a sway bar or stabilizer bar) is a U-shaped torsion spring that connects the left and right sides of your suspension. When your vehicle corners and weight shifts to the outside wheels, the anti-roll bar resists this motion by twisting, redistributing force to keep your tires more evenly loaded. Understanding how this component works helps you recognize when it needs attention and make informed decisions about maintenance and upgrades. Whether you’re navigating daily commutes or pushing through spirited canyon drives, your anti-roll bars are working behind the scenes to maintain control and confidence.

Let’s explore how these critical suspension components manage body roll, what happens when they fail, and how to keep them functioning properly to ensure your vehicle handles exactly as it should.

What is an Anti-Roll Bar?

An anti-roll bar is fundamentally a torsion spring—a metal bar designed to resist twisting forces. In automotive applications, it’s a U-shaped steel bar that spans the width of your vehicle, connecting the left and right suspension components. When you hear mechanics or enthusiasts mention “sway bars,” “stabilizer bars,” or “anti-sway bars,” they’re all referring to the same component that helps control your vehicle’s body roll during cornering and over uneven surfaces.

The primary job of an anti-roll bar is straightforward: reduce how much your vehicle’s body leans or “rolls” to the outside during cornering. When you turn left, physics wants to throw your vehicle’s weight to the right side. Without an anti-roll bar, your outside suspension would compress significantly while the inside suspension extends, creating excessive body lean. The anti-roll bar resists this differential movement by twisting, which forces the inside wheel down and prevents excessive lean. This keeps more tire contact on the road and gives you better control.

Beyond just reducing body roll, anti-roll bars serve a second critical function that professional suspension tuners rely on: they allow fine-tuning of your vehicle’s handling balance. By adjusting the stiffness of the front versus rear anti-roll bars, engineers can influence whether a vehicle tends toward understeer (front loses grip first) or oversteer (rear loses grip first). This makes the anti-roll bar an essential tool for optimizing vehicle handling characteristics.

Key Components of an Anti-Roll Bar System

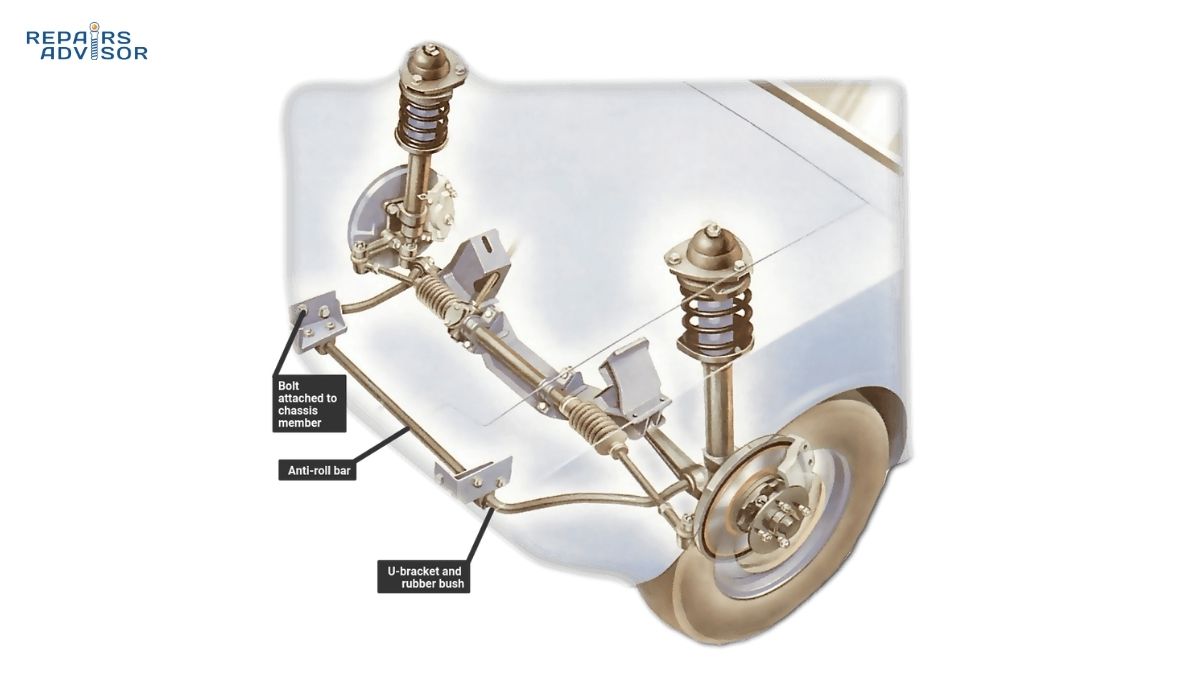

Every anti-roll bar system consists of several interconnected parts working together:

The Main Torsion Bar forms the heart of the system. Typically made from solid steel or hollow steel tubing, these bars range from 18mm to 30mm in diameter depending on the vehicle and performance requirements. The bar’s thickness has an enormous impact on its stiffness—we’ll explore the mathematics of this relationship shortly. Sports cars and performance vehicles use thicker bars to minimize body roll, while comfort-oriented vehicles use thinner bars that allow some lean for a softer ride.

End Links (also called drop links or sway bar links) are short connecting rods, usually 4 to 6 inches long, that attach at 90-degree angles to each end of the anti-roll bar. These links connect the bar to the suspension components—either the control arms on double-wishbone systems or the struts on MacPherson configurations. Most modern end links feature ball joints on each end, encased in rubber boots, which allow the necessary pivoting motion while the bar twists.

Bushings are rubber or polyurethane components that mount the center section of the anti-roll bar to the vehicle’s chassis or subframe. These bushings allow the bar to rotate freely during normal driving (when both wheels move together over bumps) while still providing a solid anchor point when the bar needs to resist twisting forces during cornering. The bushings also help isolate road noise and vibration from entering the cabin.

Mounting Brackets secure the bushings to the vehicle frame. These stamped steel or cast aluminum brackets bolt directly to the chassis and hold the anti-roll bar in position while allowing it to rotate within the bushings.

Types of Anti-Roll Bars

Not all anti-roll bars are created equal. Different designs serve different purposes:

Standard solid bars are the most common type found on production vehicles. These are exactly what they sound like—solid steel bars bent into shape. They’re cost-effective to manufacture, extremely durable, and provide predictable performance for everyday driving.

Hollow bars use tubular construction instead of solid steel. By carefully engineering the wall thickness and diameter, manufacturers can achieve the same stiffness as a solid bar while reducing weight—a critical consideration for performance vehicles where every pound matters. The trade-off is higher manufacturing cost and potentially less durability under extreme conditions.

Adjustable bars feature multiple mounting holes on the end links, allowing you to change the effective lever arm length and thus adjust the bar’s stiffness without replacing it. These are popular in motorsports and for enthusiasts who want to fine-tune their suspension setup for different driving conditions or track configurations.

Active anti-roll bars represent the cutting edge of suspension technology. Found on high-end luxury vehicles and performance SUVs from brands like Audi, Bentley, Lamborghini, Mercedes, and Rolls Royce, these systems use electric motors or hydraulic actuators at the center of the bar. The system can actually split the bar and apply opposing torque to each side in real-time, effectively creating variable stiffness that adapts to driving conditions. On the highway, they can stiffen for minimal body roll; on rough roads, they can soften or even disconnect for better comfort and articulation.

Understanding these components helps you grasp how the system works as a unit. The control arm bushings and anti-roll bar bushings work together to manage suspension movement while isolating noise—a delicate balance that requires quality components throughout the system.

How Anti-Roll Bars Work

To truly understand anti-roll bars, we need to explore the physics of cornering and how these components counteract the natural tendency for vehicles to lean.

The Body Roll Problem

When your vehicle enters a corner, physics creates a lateral force at your vehicle’s center of gravity. This force is proportional to your cornering speed and the tightness of the turn—the faster you corner or the sharper the turn, the greater this lateral force becomes. Because your vehicle’s center of gravity sits well above the road surface (typically 18 to 24 inches on passenger cars, higher on SUVs), this lateral force creates a rotational moment around what suspension engineers call the “roll axis.”

This rotational moment wants to tip your vehicle toward the outside of the turn. Your outside suspension compresses as weight transfers onto those wheels, while your inside suspension extends as weight lifts off those wheels. Without any resistance, your vehicle would lean considerably—potentially several degrees on older vehicles with soft suspension. Modern vehicles typically experience 3 to 7 degrees of body roll under normal cornering, though this varies significantly based on suspension design and tuning.

Body roll itself isn’t necessarily dangerous in moderate amounts, but it creates several problems. First, as your vehicle leans, the geometry of your suspension changes. Your tires’ contact patches shift, potentially reducing grip. The camber angles of your wheels change, which can put your tire tread at disadvantageous angles relative to the road surface. Most importantly, excessive body roll simply feels unstable and reduces driver confidence, especially during emergency maneuvers where split-second reactions matter.

This is where anti-roll bars prove their worth, working in concert with your shock absorbers and struts to control suspension movement.

Torsion Spring Mechanics in Action

The beauty of an anti-roll bar lies in its selective resistance. During straight-line driving or when both wheels encounter the same bump together, the bar simply rotates on its center bushings without providing any resistance. This is crucial—it means the anti-roll bar doesn’t stiffen your suspension for normal bumps and road imperfections, preserving ride comfort.

However, when cornering creates differential suspension movement—one side compressing while the other extends—the physics changes dramatically. Here’s what happens:

As you turn left, weight transfers to the right side of your vehicle. Your right-side suspension compresses while your left-side suspension extends. The anti-roll bar connects both sides, so as the right side tries to compress and the left side tries to extend, the bar is forced to twist. Steel resists twisting with substantial force—this is the torsion spring effect.

As the bar twists, it generates resistance forces at both ends. On the compressing side (outside of the turn), the bar resists the downward movement. More importantly, on the extending side (inside of the turn), the bar actively pushes down on the suspension, counteracting the weight unloading that would normally occur. This redistribution of force keeps the inside wheels more firmly planted on the road than they would be without the anti-roll bar.

The result is a more evenly distributed load across all four tires. Instead of the outside tires bearing most of the cornering load while the inside tires barely contact the road, the anti-roll bar helps maintain better overall tire contact. This translates to improved grip, better handling response, and reduced body roll.

The Physics of Stiffness

For those interested in the engineering details, anti-roll bar stiffness follows a precise mathematical relationship. The stiffness (K) is calculated as:

K = (G × D⁴) / (L × B²)

Where:

- K = rate in pounds per inch at the end of one arm

- G = material stiffness (shear modulus of the steel)

- D = main bar diameter

- L = length of the main bar section

- B = length of the lever arms

This formula reveals some fascinating insights. Notice that diameter (D) appears to the fourth power. This means small changes in bar diameter create enormous changes in stiffness. If you double the diameter of an anti-roll bar, you don’t double its stiffness—you increase it by a factor of 16 (2⁴ = 16). This is why you see relatively small differences in bar diameter between comfort and performance applications. A bar might increase from 24mm to 27mm—just 3mm—but that represents roughly a 60% increase in stiffness.

Conversely, the arm length (B) appears squared in the denominator, meaning longer arms reduce stiffness. Doubling the arm length quarters the stiffness. This is why adjustable anti-roll bars work—by changing where the end link attaches, you effectively change the arm length and thus the stiffness without replacing the entire bar.

Most passenger vehicles use front anti-roll bars in the 22-28mm range and rear bars in the 18-24mm range. The front is typically stiffer because most vehicles have their engines in front, creating a forward weight bias that requires more roll resistance at the front axle. Sports cars and performance vehicles push these numbers higher—some use 30mm or even larger bars for minimal body roll during aggressive driving.

The Dual Functions of Anti-Roll Bars

Understanding the two primary functions of anti-roll bars helps explain why they’re so critical to modern suspension design:

Function 1: Reducing Body Lean

The most obvious function is reducing how much your vehicle’s body rolls during cornering. By increasing the suspension’s overall roll stiffness, anti-roll bars limit the amount of lean you experience. This makes the vehicle feel more stable and planted, giving you greater confidence through corners.

It’s important to understand what anti-roll bars don’t do: they don’t change the total amount of weight transfer from inside to outside wheels. That’s determined by your vehicle’s center of gravity height and track width (the distance between left and right wheels). No amount of anti-roll bar stiffness changes these fundamentals. What the bar does change is how much the vehicle’s body visibly leans while that weight transfer occurs. Think of it as controlling the symptom (body roll) rather than the cause (weight transfer).

Function 2: Handling Balance Adjustment

This is where anti-roll bars become powerful tuning tools. By adjusting the relative stiffness of front versus rear anti-roll bars, engineers can influence which end of the vehicle loses grip first during aggressive cornering.

Increasing the front anti-roll bar stiffness increases the proportion of total load transfer that occurs at the front axle, which typically increases understeer (the tendency for the front tires to lose grip first, making the vehicle want to go straight instead of turning). This is generally considered safer behavior for everyday drivers, as understeer is more intuitive to correct—you simply slow down and the vehicle regains grip.

Conversely, increasing the rear anti-roll bar stiffness shifts more load transfer to the rear, which can increase oversteer (the rear tires lose grip first, causing the back end to slide out). In skilled hands, a touch of oversteer helps the vehicle rotate through corners more eagerly, but it requires careful throttle and steering control to manage.

This relationship between anti-roll bar stiffness and handling balance makes these components critical for suspension tuning. Race teams often carry multiple anti-roll bars of different diameters and swap them between sessions to dial in the perfect handling balance for each track. Even on street vehicles, understanding this relationship helps explain why your vehicle handles the way it does and what changes might improve it for your driving style.

The anti-roll bar works alongside other suspension components like suspension springs to control vehicle dynamics. Together, they create the total roll stiffness package that determines your vehicle’s handling characteristics.

Location and Installation

Understanding where anti-roll bars live in your vehicle helps you visualize how they work and makes it easier to inspect them for wear.

Front Anti-Roll Bar Location

On most vehicles, you’ll find the front anti-roll bar mounted transversely across the front subframe or suspension cradle, typically positioned between the lower control arms. The exact mounting varies by suspension design.

On vehicles with MacPherson strut suspension—one of the most common front suspension designs—the end links typically connect the anti-roll bar directly to the strut assembly. This is the configuration Colin Chapman pioneered with the original MacPherson strut design, where the anti-roll bar serves double duty as both a roll control device and a critical structural member that helps locate the wheel fore and aft.

On double wishbone suspension systems, the end links usually connect to the lower control arms. This placement allows the bar to resist the differential movement between left and right suspension as the control arms move through their travel.

The center section of the front anti-roll bar is secured to the subframe or chassis by rubber or polyurethane bushings held in place by stamped steel or aluminum brackets. These bushings are positioned to allow the bar to rotate freely during normal straight-line driving while providing a solid anchor when the bar twists during cornering.

Accessing the front anti-roll bar typically requires getting under the vehicle. On some cars, you can see the end links and bushings from above with the hood open, but full inspection and service usually requires lifting the vehicle on a hoist or jack stands. Removing the front wheels often provides better access to the end links for replacement.

Rear Anti-Roll Bar Location

Not all vehicles have rear anti-roll bars—it depends on the suspension design and the vehicle’s intended purpose. When present, rear bars are mounted similarly to front bars but attach to the rear suspension components.

On vehicles with independent rear suspension, the rear anti-roll bar connects to the rear control arms or the rear suspension knuckles, following the same principles as the front. The center section mounts to the rear subframe or chassis through bushings and brackets.

On vehicles with solid rear axles (common on trucks and some SUVs), the rear anti-roll bar may mount differently, sometimes connecting directly to the axle housing itself rather than to individual suspension components.

Sports cars and performance-oriented vehicles almost always have both front and rear anti-roll bars to maximize handling capability and minimize body roll. These vehicles also tend to use thicker bars than their comfort-oriented counterparts. Some luxury SUVs and crossovers may have only a front anti-roll bar, relying on other suspension components to control rear body roll.

Connection Points and Integration

The way anti-roll bars connect to your suspension reveals important details about your vehicle’s design philosophy. The connection between the bar and the suspension components must allow for the complex motion that occurs during driving—wheels moving up and down, suspension articulating through its travel, and steering inputs changing wheel positions.

This is why end links use ball joints or rubber bushings at both ends. These connections must pivot freely to accommodate suspension movement while still transmitting the torsional forces from the anti-roll bar effectively. The ball joints in end links are similar in design to steering and suspension ball joints, just smaller and with less load capacity since they primarily handle torsional forces rather than supporting the vehicle’s weight.

The center bushings where the bar mounts to the chassis serve a different purpose. These need to allow rotation around the bar’s axis during straight-line driving and when both wheels move together, but they must grip the bar firmly enough to resist rotation when the bar is being twisted during cornering. This is why the bushing material and design matter significantly—too soft and the bar can’t develop full torsional resistance; too hard and the bushings transmit excessive noise and vibration into the cabin.

On vehicles with steering knuckles, the anti-roll bar end links often connect near the knuckle’s lower mounting point, creating a mechanically efficient load path through the suspension.

Common Failure Modes and Symptoms

Anti-roll bars themselves rarely fail—they’re solid steel bars designed to last the life of the vehicle. However, the components that connect the bar to the suspension and chassis are wear items that eventually need replacement. Recognizing the symptoms of failing anti-roll bar components helps you address issues before they compromise safety or cause additional damage.

End Link and Drop Link Failure

The most common anti-roll bar-related failure involves the end links (drop links). These components experience constant movement and are exposed to road salt, water, dirt, and temperature extremes, making them vulnerable to wear.

Symptoms of failing end links:

The telltale sign is a clunking or rattling noise that occurs when turning corners, going over bumps, or driving over uneven surfaces. This sound is typically described as a light metallic rattling or knocking that seems to come from the front or rear corners of the vehicle, depending on which anti-roll bar is affected. The noise is most noticeable at low speeds over small bumps or when turning into driveways and parking lots.

You might hear the knocking through the steering wheel on front anti-roll bar end link failures, particularly when the wheel isn’t being turned. If the sound occurs mainly during cornering and seems to come from the area near the wheels, you’re likely dealing with ball joint wear in the end links rather than the center bushings.

The noise occurs because worn ball joints develop excessive play. As the suspension moves and the end link pivots, the worn ball joint allows the components to knock against each other or shift position abruptly. In severe cases, you might even feel a slight clunk through the steering wheel or chassis.

Common causes:

End link failures typically result from normal wear and tear on the ball joints. Most end links feature a rubber boot that seals the ball joint and keeps grease inside while keeping contaminants out. When this boot cracks or tears—often due to age, heat cycles, and exposure to road chemicals—water and dirt enter the joint. Once contamination occurs, the lubrication breaks down and the ball joint components begin to wear against each other.

Corrosion from road salt accelerates this process significantly. This is why vehicles in northern climates where roads are salted during winter often experience end link failures sooner than vehicles in milder climates.

Typical end link lifespan ranges from 50,000 to 100,000 miles, though some vehicles see failures as early as 40,000 miles while others go 150,000 miles or more. Driving conditions matter enormously—aggressive driving with frequent hard cornering, rough roads, and exposure to salt all reduce lifespan.

If you’re experiencing these symptoms, you might find our guide on how to tell if your front sway bar is failing helpful for diagnostic procedures.

Bushing Wear and Deterioration

The rubber or polyurethane bushings that mount the anti-roll bar to the chassis also wear over time, though they typically last longer than end links.

Symptoms of worn center bushings:

Worn bushings often announce themselves with squeaking or creaking noises when cornering. Unlike the sharp clunking of worn end links, bushing noise tends to be a deeper, more sustained sound—almost like a groan. Some describe it as similar to the sound of old bed springs.

You might also notice a heavier knock with a deeper tone compared to end link failures. This occurs when the bushings have deteriorated enough that the metal anti-roll bar can move within the bushing and contact the metal mounting bracket.

Handling changes often accompany worn bushings. You might feel that the steering has become less precise or that there’s more body roll during cornering than there used to be. The vehicle may feel slightly loose or imprecise, particularly during quick directional changes.

Common causes:

Rubber bushings harden and crack over time due to heat cycles, chemical exposure (road salt, oil, transmission fluid leaks), and simple aging. As rubber hardens, it loses its ability to flex properly, and cracks develop. Eventually, pieces may break away entirely, allowing the bar to move excessively within the bracket.

This deterioration can begin as early as 60,000 miles on some vehicles, particularly those subjected to harsh conditions. Vehicles that see a lot of stop-and-go traffic generate more heat in the suspension, which accelerates bushing degradation. Similarly, vehicles that sit unused for long periods may develop bushing cracks as the rubber dries out.

Polyurethane bushings, sometimes used in performance applications, resist chemical degradation better than rubber but can still wear, particularly if not properly lubricated during installation.

Complete Anti-Roll Bar Failure

While rare, complete failure of anti-roll bar components can occur, most commonly with the end links themselves.

Symptoms:

If an end link completely separates (the ball joint pulls apart or a plastic end link snaps), you’ll experience extreme body roll during cornering—much more than normal. The vehicle will feel unstable and uncertain, particularly during highway-speed lane changes or emergency maneuvers.

You may hear a loud snapping or popping sound when the failure occurs, followed by either silence (if the separated link is hanging freely) or violent rattling and banging (if the separated link is bouncing around under the vehicle).

Uneven tire wear can develop over time if you continue driving with a failed anti-roll bar component, as the increased body roll and unstable suspension geometry put uneven forces through the tires.

Critical Safety Warning: Driving with broken or severely worn anti-roll bar components significantly compromises your vehicle’s handling and stability, especially during emergency maneuvers when you need maximum control. While your vehicle will still be drivable in straight lines at moderate speeds, the reduced stability during cornering or evasive maneuvers poses a genuine safety risk. If you suspect anti-roll bar component failure, have your vehicle inspected by a qualified technician as soon as possible. Emergency lane changes or panic stops with a non-functioning anti-roll bar can lead to loss of control.

Professional inspection becomes particularly important because anti-roll bar symptoms can overlap with other suspension issues. Bad ball joints in the suspension or worn control arm bushings can produce similar noises and handling changes, making accurate diagnosis essential.

Maintenance and Replacement

Proper maintenance of your anti-roll bar system ensures optimal handling and prevents premature wear of other suspension components. While the bars themselves require little attention, the bushings and end links need periodic inspection and eventual replacement.

Inspection Intervals and Procedures

Regular visual inspection catches anti-roll bar problems before they compromise safety or cause additional damage. Plan to inspect these components every 6,000 miles or every six months, whichever comes first. More frequent inspection makes sense if you drive on rough roads, in areas where road salt is used, or if you’ve noticed any handling changes or unusual noises.

During inspection, look for:

End Link Condition: Check the rubber boots covering the ball joints for cracks, tears, or missing pieces. Any damage to these boots means contamination has likely entered the joint. Grasp the end link and try to move it in multiple directions—you should feel only smooth pivoting motion, no clunking or excessive play. Even small amounts of play indicate wear requiring replacement soon.

Bushing Condition: Examine the rubber or polyurethane bushings where the bar mounts to the chassis. Look for cracks, hardening, chunks missing, or bushings that appear compressed or deformed. The bushings should maintain their round shape and show no signs of deterioration. If you can see the metal bar through cracks in the bushing, replacement is overdue.

Bar Integrity: While rare, check the anti-roll bar itself for any cracks, particularly near the bends and mounting points where stress concentrates. Any cracks in the bar itself require immediate replacement as catastrophic failure could occur.

Mounting Hardware: Verify that all bolts securing the bushings and end links are tight and show no signs of loosening. Loose mounting hardware accelerates wear and can cause noise.

Professional suspension inspections typically include anti-roll bar component checks. Most mechanics recommend comprehensive suspension inspection annually or whenever you have other suspension work performed, such as shock absorber replacement.

Replacement Costs and Considerations

Understanding replacement costs helps you budget for maintenance and make informed decisions about repair timing. These are approximate costs for 2025 based on typical vehicles; luxury and specialty vehicles may see significantly higher prices.

End Links/Drop Links Replacement:

Parts costs range from $20 to $100 per end link, depending on quality and vehicle application. Budget-oriented replacement links might cost $15 to $30 each, while OEM (original equipment manufacturer) or premium aftermarket links can run $50 to $100 per side.

Labor for end link replacement typically requires 1 to 2 hours of shop time. At current labor rates of $100 to $200 per hour, expect labor charges between $100 and $200 for the job.

Total cost for replacing a pair of end links (both left and right on one axle) runs $150 to $500, including parts and labor. Most mechanics recommend replacing both sides together even if only one has failed, since the other is likely close behind and you’re already paying for the labor to access them. Replacing both ensures even suspension performance and avoids returning soon for the other side.

Bushing Replacement:

Anti-roll bar bushings themselves are inexpensive, typically costing $10 to $30 per pair for standard rubber bushings. Performance polyurethane bushings may run $30 to $60 per pair.

However, labor adds significantly to the cost. Replacing bushings requires 1 to 2 hours, translating to $70 to $160 in labor charges. The total for bushing replacement generally runs $80 to $190.

Here’s an important consideration: on many vehicles, the bushings cannot be replaced separately from the anti-roll bar itself. The bushings may be pressed into the bar in a way that makes removal destructive, or the bushing design may integrate with the bar. In these cases, you must replace the entire bar assembly, which leads to higher costs.

Complete Anti-Roll Bar Replacement:

When the entire anti-roll bar needs replacement, parts costs range from $100 to $200 per bar for most passenger vehicles. Performance or luxury vehicle bars can cost considerably more, sometimes $300 to $500 or beyond.

Labor for complete bar replacement typically runs about 2 hours at $80 to $100 per hour, for labor costs of $160 to $200.

Total cost for complete anti-roll bar replacement ranges from $260 to $400 per bar in most cases. If you’re replacing front and rear bars simultaneously, double these costs but note that you might save slightly on labor efficiency.

Additional Considerations:

After anti-roll bar component replacement, particularly complete bar replacement or if end links have been severely worn for a long time, wheel alignment is recommended. Worn anti-roll bar components can allow the suspension to operate outside normal parameters, potentially affecting alignment. A four-wheel alignment typically adds $75 to $150 to your total cost but ensures your vehicle tracks straight and tire wear stays even.

Some shops offer alignment checks free with suspension work, while others charge separately. Always ask about alignment when discussing anti-roll bar replacement.

DIY vs. Professional Service

The decision between DIY and professional service depends on your mechanical skill level, available tools, and the specific repair needed.

DIY-Friendly: End Link Replacement

End link replacement falls within reach of intermediate DIY mechanics with proper tools and safety equipment. You’ll need:

- Floor jack and quality jack stands rated for your vehicle’s weight

- Socket set with metric and standard sizes

- Torque wrench for proper tightening

- Rust penetrant for frozen fasteners

- Potentially a pickle fork or ball joint separator for stuck links

The procedure generally involves safely lifting and supporting the vehicle, removing the wheel for better access, unbolting the old end link from both the anti-roll bar and the suspension component, and installing the new link with proper torque. Most passenger vehicles use relatively straightforward fasteners, making this a manageable weekend project for someone comfortable working under their vehicle.

Professional Recommended: Complete Bar and Bushing Service

Complete anti-roll bar replacement and bushing service often benefit from professional service for several reasons:

Professional shops have vehicle lifts that provide safer access and better working positions than jack stands. The work requires manipulating heavy components while working underneath the vehicle—not the safest solo operation.

Some vehicles require partial removal of other components (exhaust pipes, suspension cross-members, heat shields) to access the anti-roll bar mounting points. Professional mechanics have experience with these vehicle-specific procedures and the specialized tools to handle them efficiently.

Most importantly, anti-roll bar service often necessitates wheel alignment afterward. Professional shops can perform both the mechanical replacement and the alignment in one visit, ensuring your vehicle handles correctly when you drive away.

Safety Considerations for DIY Work:

If you choose to replace end links yourself, never rely solely on a floor jack to support the vehicle—always use jack stands rated for your vehicle’s weight, positioned on solid frame points. Work on level ground, set the parking brake, and chock the wheels that remain on the ground.

Wear safety glasses—rust and corrosion from fasteners can flake off into your eyes. Have rust penetrant available for seized bolts, which are common on suspension components exposed to road salt and moisture.

Professional Consultation Recommendation: While end link replacement can be DIY-friendly for mechanically inclined individuals with proper tools and safety equipment, complete anti-roll bar service and bushing replacement often requires professional expertise, specialized equipment, and alignment services to ensure proper handling characteristics and safety. If you’re uncertain about any aspect of the repair, or if your vehicle requires alignment afterward, professional service provides peace of mind and ensures the work is done correctly.

Performance Upgrades and Tuning

Beyond maintenance, many enthusiasts explore anti-roll bar upgrades to improve handling or adjust their vehicle’s behavior for specific driving conditions. Understanding the effects of different modifications helps you make informed decisions about performance upgrades.

Aftermarket Anti-Roll Bar Options

The aftermarket offers several types of anti-roll bar upgrades for vehicles ranging from daily drivers to dedicated track cars:

Thicker Bars are the most common upgrade. By increasing the bar diameter from, say, 24mm to 27mm, you dramatically increase stiffness and reduce body roll. Remember the fourth-power relationship we discussed—these seemingly small diameter increases create substantial stiffness gains. Thicker bars make your vehicle feel more planted through corners and can increase confidence during spirited driving.

However, thicker isn’t always better. Excessively stiff anti-roll bars can make the ride feel harsh over bumps, particularly if you drive frequently on rough roads. The increased stiffness also affects how the suspension reacts to single-wheel bumps, potentially reducing overall compliance. The goal is finding the right balance between reduced body roll and maintained ride quality.

Adjustable End Links become important when you’ve lowered your vehicle or made other suspension modifications. Aftermarket height-adjustable end links allow you to fine-tune the preload on the anti-roll bar and ensure proper geometry after ride height changes. Some adjustable links also offer different stiffness settings by changing where they connect to the bar, effectively changing the lever arm length.

Polyurethane Bushings replace the stock rubber center bushings with stiffer polyurethane. These reduce compliance in the bushing, allowing the anti-roll bar to respond more quickly and directly to suspension movement. The trade-off is slightly increased noise transmission into the cabin—polyurethane doesn’t isolate vibration as effectively as rubber. However, quality polyurethane bushings significantly outlast rubber, often lasting 200,000 miles or more.

Complete Bar Kits from performance suspension companies like Eibach, H&R, Whiteline, and others offer engineered solutions with carefully selected diameters for front and rear bars. These kits consider the complete suspension package and aim to improve handling without creating unwanted behavior.

Tuning Considerations for Different Applications

The right anti-roll bar setup depends on how you use your vehicle:

Track Day and Autocross Applications:

Serious track drivers typically run stiffer anti-roll bars front and rear to minimize body roll during aggressive cornering. Common configurations use 26-30mm front bars and 22-26mm rear bars, depending on the vehicle. The goal is reducing roll to keep tire contact patches optimized through high-speed corners.

Track tuning often involves testing different bar combinations to dial in the perfect balance between rotation (the car’s willingness to change direction) and stability (resistance to sudden breakaway). This is where adjustable bars prove valuable—you can test different stiffness settings to find what works best for each track’s characteristics.

Drag Racing:

Drag racers often remove the front anti-roll bar entirely or run extremely soft front bars. Why? During launch, you want maximum weight transfer to the rear tires for traction. A stiff front anti-roll bar resists the chassis twist that helps load the rear tires, potentially hurting launch performance.

However, this makes the vehicle extremely soft in front-end cornering, so drag-only setups aren’t safe for street driving. If you drive to the track, you need to compromise or have a way to disconnect/remove the front bar at the track.

Street Performance:

For vehicles that see spirited street driving but remain daily drivers, the sweet spot usually involves moderately stiffer bars that reduce body roll without destroying ride quality. A 10-20% increase in stiffness over stock often provides noticeably improved handling while maintaining reasonable comfort over typical road imperfections.

Many street performance enthusiasts run a slightly stiffer rear bar than stock to add a touch of rotation and reduce understeer, making the vehicle feel more neutral and responsive in corners. This works particularly well on front-wheel-drive vehicles, which tend toward understeer in stock form.

Off-Road Applications:

Off-road vehicles face opposite requirements from track cars. Maximum suspension articulation—the ability for wheels to move independently over obstacles—requires minimal anti-roll bar interference. Many serious off-road vehicles use disconnectable anti-roll bar links that can be unhooked before hitting trails, then reconnected for highway driving.

Some off-road vehicles run no anti-roll bars at all, relying instead on shock tuning and spring rates to control body movement. The trade-off is increased body roll on pavement, but improved wheel articulation over rocks and uneven terrain.

Handling Balance Effects and Safety Considerations

Modifying anti-roll bar stiffness changes your vehicle’s fundamental handling balance, sometimes in surprising ways. A stiffer front bar increases understeer—the front tires lose grip before the rears. For most drivers, particularly on the street, this is the safer behavior because understeer is intuitive to correct: you’re trying to turn and the vehicle wants to go straight, so you slow down and grip returns.

Conversely, a stiffer rear bar can increase oversteer—the rear tires lose grip before the fronts, causing the back end to step out. Skilled drivers can use this rotation to their advantage, but it requires experience and quick reactions to control. Excessive rear bar stiffness can create snap oversteer in certain situations, which catches even experienced drivers off guard.

Critical Safety Note: Modifying anti-roll bar stiffness significantly affects how your vehicle handles, potentially in unexpected ways. Professional suspension tuning and four-wheel alignment are strongly recommended after any anti-roll bar modifications to ensure safe, predictable behavior. What works well on a race track with experienced drivers may be dangerous on public roads with varying conditions and traffic. Always test modified suspension carefully in controlled environments before pushing the limits, and consider having a professional suspension specialist review your setup.

Anti-roll bar modifications work best as part of a complete suspension package. Changing only the anti-roll bars while leaving aged shock absorbers or worn suspension springs can create imbalanced behavior that feels unpredictable. The most successful upgrades consider the entire system.

Integration with Suspension Systems

Anti-roll bars don’t work in isolation—they’re part of your vehicle’s complete suspension system, working alongside springs, dampers, and other components to control vehicle motion and handling.

How Anti-Roll Bars Interact with Other Suspension Components

Your vehicle’s total roll stiffness comes from two sources: the springs and the anti-roll bars. The springs provide the baseline resistance to body roll through their vertical stiffness. The anti-roll bars add to this total roll stiffness but only when left and right wheels move differently—they don’t affect spring rates for normal bumps.

This selective operation is crucial. If you increased spring rates to achieve the same roll control as a properly sized anti-roll bar, your vehicle would have an extremely harsh ride over bumps. The springs would resist all vertical movement, wanted or not. The anti-roll bar’s genius is providing roll resistance without affecting ride quality over typical road imperfections.

Shock absorbers and struts control the speed of suspension movement, damping oscillations so your springs don’t bounce uncontrollably. The anti-roll bar affects how much movement occurs between left and right wheels, while shocks control how quickly that movement happens. Together, they create controlled, predictable suspension behavior.

The relationship between components means that worn shocks can make anti-roll bar problems worse and vice versa. If your shocks are worn and allowing excessive suspension movement, even a good anti-roll bar struggles to control body roll effectively. Similarly, worn anti-roll bar components can create the impression of worn shocks because the excessive roll affects how the suspension responds.

This is why comprehensive suspension evaluation considers all components together rather than in isolation. The complete system integration determines your vehicle’s ride and handling characteristics.

Modern Advanced Anti-Roll Bar Systems

While most vehicles use the traditional passive anti-roll bar design we’ve discussed, high-end vehicles increasingly employ sophisticated active anti-roll bar systems that adapt in real-time to driving conditions.

Active Anti-Roll Bar Technology:

Active systems use electric motors or hydraulic actuators positioned at the center of the anti-roll bar. These systems can actually split the bar into two independent sections and apply opposing forces to each side. By varying the torque applied, the system can effectively change the anti-roll bar stiffness on demand—even making the bar completely ineffective for maximum comfort, or extremely stiff for maximum roll control.

Current implementations use 48-volt electrical systems to power the actuators. Vehicles from Audi, Bentley, Lamborghini, Mercedes-Benz, and Rolls-Royce feature these systems, particularly on larger SUVs and luxury sedans where the benefits are most pronounced.

The active system monitors vehicle speed, steering angle, lateral acceleration, and sometimes even reads the road ahead using cameras. During gentle highway cruising, the system can disconnect or minimize anti-roll bar stiffness, allowing each wheel to respond independently to road irregularities for maximum comfort. When sensors detect aggressive cornering, the system instantly applies maximum stiffness to minimize body roll and maintain tire contact.

For off-road capable luxury SUVs, active anti-roll bars offer enormous benefits. On pavement, they provide sports-car-like body control and minimal roll. On trails, they can disconnect completely, allowing the massive suspension articulation needed to keep all wheels on the ground over obstacles. This versatility would be impossible with passive anti-roll bars.

Future Developments:

The technology continues to evolve. Some manufacturers are developing systems that can actually apply torque in the opposite direction of natural roll—actively lifting the inside of the vehicle during cornering rather than just resisting roll. This could theoretically create negative body roll, where the vehicle leans into turns like a motorcycle rather than away from them.

These advanced systems complement other modern technologies like active suspension and air suspension, working together to provide unprecedented control over vehicle behavior. As the technology becomes more affordable, we’ll likely see active anti-roll bars trickle down from luxury vehicles to mainstream applications.

Conclusion

Anti-roll bars represent one of those elegant engineering solutions that solve multiple problems simultaneously. By connecting the left and right sides of your suspension through a torsion spring, they reduce body roll without affecting ride quality, improve tire contact during cornering, and provide a powerful tool for tuning handling balance. From the perspective of a daily driver navigating city streets to a performance enthusiast attacking canyon roads, properly functioning anti-roll bars contribute to vehicle control and confidence.

The key points to remember:

Functionality: Anti-roll bars work by resisting differential suspension movement through torsion spring action. They reduce body roll during cornering while allowing normal suspension movement over bumps, maintaining ride comfort while improving handling.

Dual Purpose: Beyond reducing body lean, anti-roll bars serve as tuning tools for adjusting handling balance. The relative stiffness of front versus rear bars influences whether a vehicle tends toward understeer or oversteer.

Component Wear: While the bars themselves typically last the vehicle’s lifetime, end links and bushings are wear items requiring periodic replacement. End links commonly need replacement every 50,000 to 100,000 miles, while bushings may last 60,000 miles or more depending on conditions.

Failure Symptoms: Watch for clunking or rattling noises when cornering or over bumps, squeaking during turns, excessive body roll, or loose steering feel. These indicate worn end links or bushings requiring attention.

Replacement Costs: Budget $150-$500 for end link replacement per axle, $80-$190 for bushings, or $260-$400 for complete anti-roll bar replacement. Professional installation ensures proper torque and alignment.

Maintenance: Inspect anti-roll bar components every 6,000 miles or six months, looking for worn bushings, damaged end link boots, loose fasteners, or excessive play in the connections.

When to Seek Professional Help

Several situations warrant professional attention:

Any handling changes beyond normal wear—if your vehicle suddenly feels different through corners or during lane changes, have a professional inspect the suspension system. Worn anti-roll bar components often develop gradually, but sometimes failures can be sudden.

Before modifying anti-roll bars for performance—if you’re considering upgraded bars for better handling, consult with a suspension specialist who can recommend appropriate stiffness levels and ensure proper installation and alignment afterward.

After any suspension component replacement—wheel alignment should be checked after replacing anti-roll bars or end links, particularly if they’ve been worn for a long time, as the suspension may have been operating outside normal parameters.

Annual comprehensive suspension inspection—even if you don’t notice specific symptoms, professional inspection catches developing issues before they become safety concerns or cause additional damage.

Educational Resources and Next Steps

Understanding how anti-roll bars integrate with your complete suspension system empowers you to make informed maintenance decisions and recognize early warning signs of wear. The knowledge helps you communicate more effectively with service professionals and understand their recommendations.

For comprehensive information about maintaining and repairing suspension components, including anti-roll bars and their related systems, explore our complete collection of steering and suspension repair manuals. These resources provide detailed guidance for maintaining the critical components that keep your vehicle stable, predictable, and safe through every corner.

Your anti-roll bars work silently in the background during every drive, managing forces you rarely think about but always rely on. By understanding their function, recognizing when they need attention, and maintaining them properly, you ensure these critical components continue providing the stability and control that make modern vehicles safe and enjoyable to drive.