Modern luxury and performance vehicles possess a remarkable ability—they can transform their character instantly, morphing from comfortable cruisers to precision handling machines in milliseconds. This technological marvel is active suspension, a sophisticated system that revolutionizes how vehicles interact with the road. Unlike traditional passive suspension that relies on fixed springs and dampers to provide a single compromise between comfort and handling, active suspension uses electronic control, advanced sensors, and intelligent actuators to continuously adapt suspension characteristics in real-time.

Active suspension represents one of the most significant advances in automotive chassis technology. The system monitors vehicle dynamics and road conditions hundreds of times per second, making instantaneous adjustments to damping forces, suspension stiffness, and even ride height. This eliminates the age-old engineering compromise: you no longer choose between a plush ride and sharp handling—active suspension delivers both by adapting to current conditions and driver demands.

The technology’s evolution traces back to Formula One racing in the 1980s, where teams like Lotus pioneered computer-controlled suspension systems that kept race cars perfectly balanced through corners. Today, active suspension has matured into reliable production systems found in vehicles from Mercedes-Benz, Audi, BMW, and even electric vehicle manufacturers like Tesla and Lucid. As autonomous driving and vehicle electrification advance, active suspension becomes increasingly important—not just for performance, but for passenger comfort, safety, and energy efficiency.

Understanding how active suspension works reveals the sophisticated integration of mechanical engineering, hydraulics, electronics, and control algorithms. This knowledge helps you appreciate the technology in modern vehicles and understand why these systems require professional expertise for diagnosis and service. Before we explore the complexities of active suspension, it’s helpful to understand conventional suspension systems and how traditional shock absorbers and struts create the baseline that active systems enhance.

Why Active Suspension Transforms Vehicle Performance and Comfort

The fundamental challenge in suspension design has remained constant for over a century: springs and dampers that provide a comfortable ride typically allow excessive body motion during dynamic maneuvers, while stiff suspension that delivers sharp handling transmits every road imperfection directly to passengers. This compromise has forced engineers to tune suspension for the vehicle’s primary purpose—luxury sedans lean toward comfort, sports cars prioritize handling, and most vehicles split the difference with mediocre performance in both areas.

The Passive Suspension Compromise

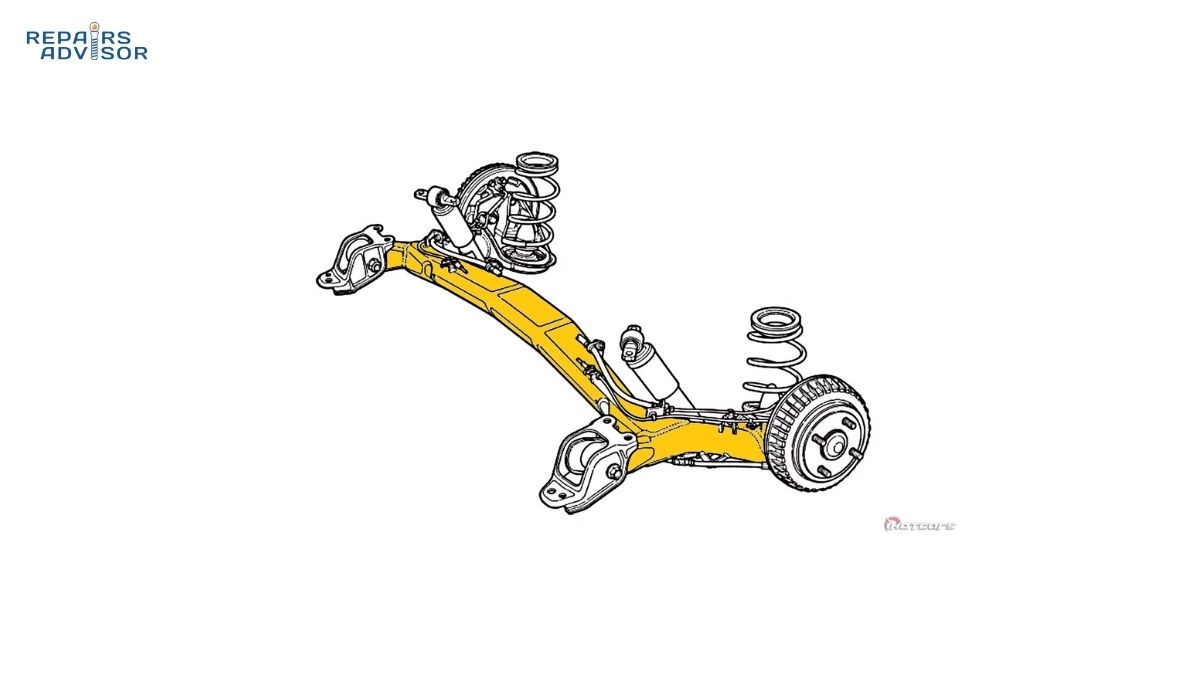

Traditional passive suspension uses springs with fixed rates and dampers with predetermined characteristics that cannot change during operation. When your vehicle encounters a bump, the suspension springs compress to absorb the impact, then rebound. Shock absorbers control this oscillation by forcing hydraulic fluid through calibrated orifices—the size of these orifices determines damping force. Once manufactured, these characteristics remain fixed.

This creates inevitable compromises. Soft springs and light damping provide excellent ride comfort by allowing the suspension to absorb bumps easily, but the same compliance permits excessive body roll during cornering, nose dive under braking, and squat during acceleration. The vehicle feels floaty and imprecise, with delayed responses to steering inputs. Conversely, stiff springs and heavy damping minimize body movements and deliver sharp handling, but transmit road harshness directly to passengers, creating an uncomfortable, fatiguing ride.

The road surface constantly changes—smooth highway transitions to broken pavement, then to expansion joints, then back to smooth sections—but passive suspension cannot adapt. Its response remains identical whether cruising at highway speed or navigating a winding mountain road. The driver experiences either consistent comfort with compromised handling, or consistent handling with compromised comfort. There’s no way to optimize for both simultaneously.

Active Systems Eliminate Trade-Offs

Active suspension fundamentally changes this equation by making suspension characteristics variable in real-time. The system continuously monitors vehicle dynamics through an array of sensors measuring acceleration, body roll, pitch, wheel position, steering angle, and even road surface conditions ahead. An electronic control unit (ECU) processes this data in cycles measured in milliseconds, calculating optimal suspension settings for current conditions. Actuators then adjust damping forces, and in some systems suspension stiffness or ride height, to match these requirements.

This real-time adaptability means the suspension can be soft when driving over highway expansion joints, providing excellent comfort, then instantly stiffen when you enter a corner, minimizing body roll and maintaining precise control. The system responds to road conditions and driver inputs faster than any mechanical system possibly could—some active suspension systems adjust damping in under 10 milliseconds, faster than the wheel can fully react to a road irregularity.

Modern predictive active suspension systems take this further by using forward-facing cameras to scan the road 15 to 50 feet ahead. When the camera detects a bump or pothole, the system pre-adjusts the relevant suspension corner before the wheel reaches the irregularity. This proactive rather than reactive approach delivers remarkably smooth ride quality—the vehicle glides over road imperfections that would jostle passengers in conventional suspension. Mercedes-Benz’s Magic Body Control and Audi’s Predictive Active Suspension exemplify this technology, using camera data combined with GPS navigation information to prepare for road conditions.

The performance benefits extend across multiple dimensions. Active suspension optimizes tire contact with the road surface by controlling how weight transfers during acceleration, braking, and cornering. This improves both safety and performance—better tire contact means shorter stopping distances, increased grip in corners, and enhanced stability during emergency maneuvers. The system can reduce body roll in corners from 10-20 degrees in conventional suspension to just 2-5 degrees, dramatically improving both comfort and control.

Real-World Performance Benefits

For drivers, active suspension delivers tangible improvements in daily driving. Ride quality improves dramatically because the suspension can remain soft over bumps while preventing the excessive oscillations that create that “floating” feeling. Long highway drives become less fatiguing because the system filters out the constant small irregularities that accumulate into discomfort over hours. Passengers notice reduced motion sickness because body movements remain minimal and controlled.

Handling characteristics transform based on driving style. During spirited driving on winding roads, active suspension stiffens to provide sports-car-like precision and control. The vehicle feels planted and responsive, with minimal body lean telegraphing exactly what the chassis is doing. Yet when returning to normal cruising, the same vehicle provides luxury-car comfort. This adaptability means a single vehicle can serve multiple roles—comfortable daily commuter and capable weekend performance machine.

Safety improves through better vehicle control in emergency situations. When you brake hard, active suspension can prevent nose dive that reduces rear brake effectiveness and creates instability. During emergency lane changes, the system minimizes weight transfer that could overwhelm tire grip. If the vehicle begins to slide, active suspension works with electronic stability control to help maintain vehicle attitude and restore traction. The integration with anti-roll bars and other suspension components creates a comprehensive chassis control system.

For towing and hauling, active suspension provides significant advantages. The system automatically adjusts to compensate for additional weight, maintaining level ride height and appropriate damping. A vehicle might squat several inches when loaded with passengers and cargo using passive suspension, but active systems maintain factory ride height and handling characteristics. This proves especially valuable in SUVs and trucks where load varies dramatically between unloaded and fully loaded conditions. Similar benefits appear in air suspension systems that combine ride height adjustment with adaptive damping.

Professional Applications and Advanced Implementations

High-end luxury vehicles showcase active suspension’s ultimate capabilities. Mercedes-Benz’s Magic Body Control, found on S-Class and select other models, uses stereo cameras to scan the road ahead at speeds up to 80 mph. The system identifies bumps, potholes, and other irregularities, then adjusts suspension at each wheel individually to compensate. The result approaches the smoothness of trains on rails—occupants barely notice road imperfections that would be jarring in conventional vehicles.

Audi’s Predictive Active Suspension takes a different approach with electromechanical actuators powered by a 48-volt electrical system. Each wheel has its own electric motor connected to a rotary tube with an internal titanium torsion bar. These actuators can exert forces up to 1,100 Newton-meters (810 foot-pounds) on the suspension, actively lifting and lowering individual wheels. Combined with camera-based road scanning, the system can literally lift a wheel over a pothole before impact occurs.

Performance vehicles use active suspension to enhance track capability while maintaining street driveability. Ferrari’s magnetorheological dampers adjust damping force within milliseconds, allowing the suspension to remain compliant over track surface irregularities while firmly controlling body movements during high-speed cornering. The system integrates with vehicle dynamics control, adjusting suspension characteristics based on selected driving mode—comfortable for street driving, progressively firmer through Sport and Race modes for track use.

Electric vehicles benefit particularly from active suspension because battery packs create unique weight distribution challenges. The Tesla Model S and Model X use adaptive air suspension to manage the low center of gravity created by floor-mounted batteries while compensating for the substantial weight. The system can also lower the vehicle at highway speeds to reduce aerodynamic drag, extending driving range—every bit of efficiency matters in electric vehicles, and active suspension contributes by optimizing the balance between ride quality and aerodynamic performance.

Safety Note: Active suspension systems are safety-critical components that directly affect vehicle control and stability. These systems operate continuously while driving, making split-second adjustments that influence handling characteristics. Failures or improper service can create unpredictable and potentially dangerous handling behavior. Any issues with active suspension require immediate professional attention from factory-trained technicians with access to manufacturer diagnostic systems and repair procedures.

Active Suspension Systems Explained: Types and Classifications

Active suspension technology encompasses several distinct approaches, each with unique characteristics, advantages, and applications. Understanding these differences clarifies why certain vehicles use specific technologies and helps explain the varying performance, cost, and complexity levels across different implementations.

Classification: True Active vs. Semi-Active Systems

The automotive industry broadly categorizes active suspension into two main classes based on their ability to introduce energy into the suspension system.

Fully Active Suspension represents the most sophisticated and capable technology. These systems use powerful hydraulic or electromagnetic actuators that can actively push and pull on the suspension, introducing energy to counteract body movements. Unlike passive dampers that can only dissipate energy by resisting motion, fully active actuators can force the chassis to move in specific directions. When the system detects an upcoming bump from camera data, for example, it can actively lift that corner of the vehicle before the wheel encounters the irregularity.

Fully active systems control the complete bandwidth of suspension frequencies. They manage low-frequency body motions like roll during cornering (typically 0.5-2 Hz), intermediate-frequency ride motions over road undulations (2-8 Hz), and even high-frequency wheel hop motions when tires encounter sharp bumps (8-15 Hz). This comprehensive control delivers the best possible ride quality and handling, but comes with significant complexity, cost, and power consumption. Systems like Mercedes-Benz Active Body Control (ABC) and the Bose electromagnetic suspension concept exemplify fully active technology.

The power requirements prove substantial—hydraulic pumps for active systems can draw 2-5 kilowatts continuously, with peak demands reaching 10 kilowatts or more during aggressive driving. This energy consumption impacts fuel economy in conventional vehicles and reduces range in electric vehicles, creating an engineering trade-off between suspension performance and efficiency.

Semi-Active (Adaptive) Suspension takes a more practical approach by varying damping force in real-time without adding energy to the system. These systems can only dissipate energy—they cannot push or pull on the chassis. The key component is an electronically controlled damper that can vary its resistance to motion from very soft to very firm in milliseconds. This allows the suspension to adapt damping characteristics to current conditions, providing much of active suspension’s benefit at lower cost, complexity, and power consumption.

Semi-active systems excel at controlling body motions and ride quality by intelligently varying when and how strongly dampers resist suspension movement. When a wheel encounters a bump, the system can temporarily reduce damping to allow the wheel to move freely over the obstacle without transmitting the impact to the chassis. Then, as the suspension rebounds, damping instantly increases to prevent oscillation. This selective damping proves remarkably effective—semi-active systems can deliver 70-80% of fully active suspension’s benefits while consuming only a fraction of the power.

The limitations appear in situations requiring active force generation. Semi-active systems cannot actively lift a corner of the vehicle or completely eliminate body roll—they can only minimize these motions by selectively resisting unwanted movements. However, for most driving situations, this proves entirely adequate. The combination of lower cost (roughly half that of fully active systems), reduced complexity, and minimal power consumption (typically under 100 watts) makes semi-active technology the most common choice for production vehicles.

Low Bandwidth (Band-Limited) Active Systems represent a middle ground, using actuators in series with conventional springs and dampers. These systems actively control low-frequency body motions—roll during cornering, pitch during braking and acceleration, and heave over larger road undulations. Higher frequency wheel motions are controlled passively by conventional damper action. This approach balances active suspension’s benefits with practical constraints of cost and power consumption. When the actuators lock up at higher frequencies, the suspension behaves conventionally, limiting power requirements while still eliminating most objectionable body motions that affect ride quality and handling.

Technology Types by Actuation Method

Within these broad categories, several distinct technologies deliver active suspension control through different actuation mechanisms.

Hydraulic Active Suspension pioneered the field and remains common in high-end applications. An engine-driven or electric hydraulic pump maintains system pressure between 2,000 and 3,000 PSI—substantially higher than typical power steering systems. This high-pressure hydraulic fluid flows to actuators at each wheel through electronically controlled valves. The actuators can be double-acting cylinders that replace conventional dampers entirely, or they may supplement existing suspension components.

The hydraulic approach offers several advantages. High-pressure hydraulics can generate substantial forces—enough to completely support the vehicle’s weight at each corner. Response times prove excellent when using modern high-speed valves. The technology is mature and well-understood, with proven reliability when properly maintained.

However, hydraulic systems come with challenges. The high pressures create safety concerns—a hydraulic line failure can spray fluid considerable distances and create slip hazards. The systems are complex, requiring pumps, accumulators (which store pressurized fluid for rapid response), control valves, extensive hydraulic lines, and filtration systems. Hydraulic fluid contamination can damage precision components, necessitating proper maintenance. The continuous operation of high-pressure pumps consumes significant power, affecting fuel economy or electric vehicle range.

Citroën pioneered production hydraulic suspension in 1954 with their hydropneumatic system, which used nitrogen-charged accumulators combined with hydraulic control. This technology evolved over decades, appearing in vehicles from the iconic Citroën DS to modern applications. Mercedes-Benz developed this concept further with Active Body Control, integrating electronic control to create one of the first fully active production suspension systems in the late 1990s.

Electromagnetic Active Suspension represents the newest approach, using linear electric motors at each wheel to generate suspension forces. These motors connect directly to the suspension, replacing conventional dampers. When energized, they can push or pull with considerable force—Audi’s electromechanical system generates up to 1,100 Newton-meters of torque through a rotary actuator connected to an internal torsion bar.

The electromagnetic approach offers compelling advantages. Response times exceed even the fastest hydraulic systems—electromagnets can change force output in under a millisecond. The technology integrates naturally with vehicle electrification trends, operating on 48-volt electrical systems that are becoming standard in modern vehicles. Perhaps most impressively, electromagnetic actuators can operate as generators during compression, recovering energy that would otherwise be wasted as heat in conventional dampers. This regenerative capability partially offsets the power consumption, improving overall efficiency.

Current limitations include higher cost than hydraulic systems and substantial power requirements—though less than hydraulic systems, electromagnetic actuators still demand significant electrical power during active control. The 48-volt electrical architecture necessary to supply sufficient current adds cost and complexity. However, as vehicles electrify and 48-volt systems become standard for other functions (like electric turbocharging and mild hybrid systems), these obstacles diminish.

Bose Corporation developed a groundbreaking electromagnetic suspension system in the 2000s, demonstrating remarkable capabilities including the ability to keep a vehicle completely level while driving over extreme obstacles. Though never reaching production due to cost and power consumption concerns, this research influenced later developments like Audi’s electromechanical active suspension introduced in 2017.

Magnetorheological Dampers (MagneRide) represent an elegant semi-active solution that has achieved widespread adoption. These dampers contain specially formulated fluid with microscopic iron particles suspended in synthetic oil. Under normal conditions, these particles move freely, allowing the fluid to flow with minimal resistance. When a magnetic field is applied by an electromagnetic coil integrated into the damper, the iron particles align into chains along the magnetic field lines.

This alignment doesn’t actually thicken the fluid in the traditional sense—instead, the organized particle chains create structure within the fluid, dramatically increasing resistance to flow. The effect occurs almost instantaneously, allowing damping force to change from minimum to maximum in less than 10 milliseconds. By varying the magnetic field strength, the system can achieve any damping force between these extremes with precise control.

The beauty of magnetorheological technology lies in its simplicity and reliability. The dampers themselves are passive—they’re just tubes containing special fluid with electromagnetic coils. There are no complex mechanical valves, no high-pressure hydraulic systems, and no moving parts inside the damper to wear out. Power consumption is minimal—the electromagnetic coils draw only a few watts per corner. Yet the performance approaches that of fully active systems for controlling ride and handling.

General Motors pioneered production magnetorheological suspension with their MagneRide system, first appearing in 2002 Cadillac models. The technology has since spread to numerous manufacturers, including Ferrari (where it’s called SCM-E for Sospensione a Controllo Magnetoreologico Evoluto), Audi, and others. Each implementation refines the concept, but the core technology remains remarkably elegant in its simplicity.

Electronically Controlled Air Suspension combines air springs (which replace conventional coil springs) with electronic control valves that adjust air pressure and damping characteristics. Air springs use compressed air in rubber bladders to support vehicle weight—increasing pressure raises ride height and stiffens the spring rate, while decreasing pressure lowers the vehicle and softens the ride.

Modern air suspension systems integrate variable damping control, creating a complete adaptive suspension package. The ability to adjust both spring rate and damping independently provides exceptional versatility. The system can raise ride height for off-road driving or loading passengers, lower it for improved aerodynamics at highway speeds, and adjust spring/damping rates for optimal ride and handling.

Air suspension proves particularly popular in luxury SUVs and electric vehicles. The self-leveling capability maintains consistent ride height regardless of load—invaluable for vehicles that frequently transition between unloaded and fully loaded conditions. In electric vehicles, the ability to lower the body at highway speeds reduces aerodynamic drag, extending range. However, air suspension systems add complexity with their compressors, air reservoirs, control valves, and air lines, and they consume power to maintain pressure. Reliability concerns also exist—air springs can develop leaks, and the complex pneumatic system requires more maintenance than conventional springs.

Valve-Actuated Adaptive Dampers represent the most common semi-active technology due to their relatively simple design and low cost. These dampers use electronically controlled valves inside a conventional damper body. The valves regulate fluid flow between chambers—restricting flow increases damping force (firm), opening the valve reduces damping (soft). Modern systems can adjust these valves in milliseconds, providing continuously variable damping that adapts to driving conditions.

Most production vehicles with “adaptive suspension” or “dynamic damping control” use valve-actuated systems. They’re offered across a wide range of vehicles from mainstream to luxury brands, typically providing driver-selectable modes (Comfort, Normal, Sport) that alter damping characteristics. The technology proves cost-effective because it builds on proven conventional damper designs with the addition of electronic valves and control electronics.

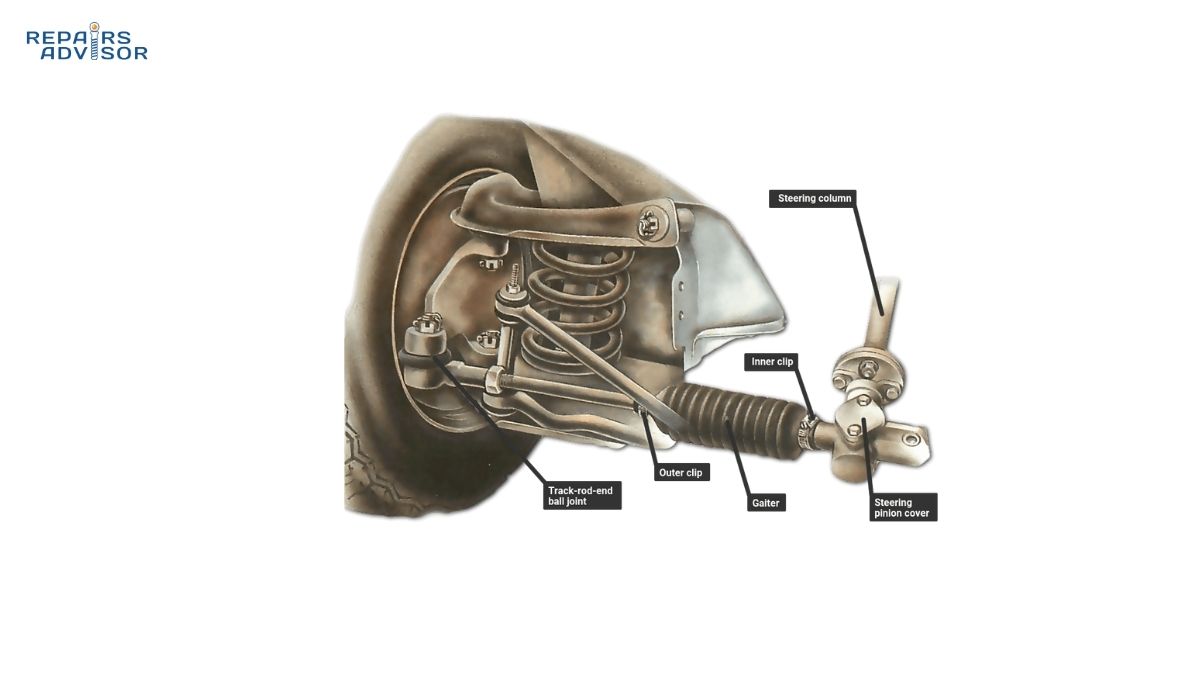

The relationship between active suspension and the broader suspension system involves integration with many components. Control arms and ball joints provide mounting points and pivot locations for actuators. In MacPherson strut designs, active dampers replace conventional struts while maintaining the same mounting points. More complex multi-link suspension architectures can accommodate active components with minimal redesign. The active suspension must work within the constraints of suspension geometry while delivering its performance benefits.

Professional Context: Selecting the appropriate active suspension technology involves balancing performance requirements against practical constraints of cost, complexity, power consumption, and maintenance needs. Fully active hydraulic or electromagnetic systems deliver ultimate performance but at substantial cost and complexity—typically reserved for ultra-luxury and high-performance vehicles. Semi-active magnetorheological and valve-actuated systems provide excellent performance with greater practicality, making them suitable for mainstream luxury and performance applications. The choice depends on vehicle positioning, target market, and engineering priorities. Professional technicians must understand these differences to properly diagnose and service each system type using appropriate equipment and procedures.

How Active Suspension Components Work Together

Active suspension systems integrate mechanical, hydraulic, electrical, and electronic components into a sophisticated mechatronic system. Understanding how these elements work together reveals the complexity and intelligence built into modern chassis control.

Core Component Architecture

The active suspension system functions as a closed-loop control system, continuously monitoring conditions, making decisions, and implementing corrections. This cycle repeats dozens or hundreds of times per second, creating the seamless real-time adaptation that defines active suspension performance.

Sensors – The System’s Nervous System

Active suspension relies on extensive sensor networks to understand what the vehicle and road surface are doing at any moment. The quantity and sophistication of sensors directly influence system performance—more information enables better control decisions.

Accelerometers form the foundation of the sensor array, measuring vertical acceleration at multiple points on the vehicle body and at each wheel. Body accelerometers detect when the chassis begins to roll during cornering, pitch during braking or acceleration, or heave over road undulations. Wheel accelerometers sense impacts from road irregularities before they can transmit to the body. Modern MEMS (Micro-Electro-Mechanical Systems) accelerometers provide precise measurements while being compact and relatively inexpensive.

Height sensors, typically using Hall effect or ultrasonic technology, measure the distance between the vehicle body and each wheel. This data determines current ride height and how far the suspension has traveled from its static position. The ECU uses this information to detect body roll during cornering, pitch during braking/acceleration, and to maintain correct ride height in systems with air springs or hydraulic actuators. Some systems measure suspension position hundreds of times per second to detect even small movements.

Wheel speed sensors, borrowed from ABS systems, provide data on individual wheel rotation. The ECU can compare wheel speeds to detect loss of traction and wheel lift during aggressive cornering. This data integrates with active suspension control to optimize tire contact.

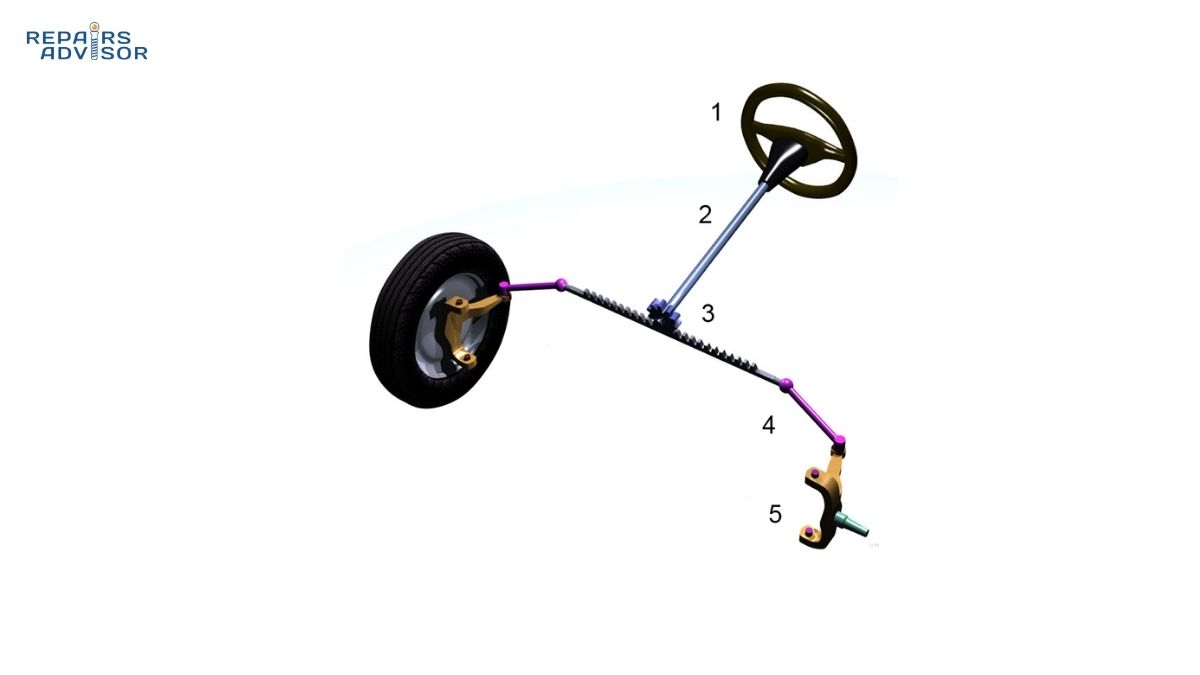

The steering angle sensor tells the system when the driver is turning and how sharply, allowing anticipatory suspension stiffening before lateral forces build. During a turn, the system knows which side of the vehicle will experience compression (outside) and extension (inside), enabling proactive damping adjustments.

Pressure sensors in hydraulic active systems monitor fluid pressure throughout the circuit, ensuring the pump maintains correct pressure and detecting leaks or component failures. These sensors provide critical diagnostic information and enable safety monitoring.

Gyroscopes measure vehicle pitch rate and roll rate—how quickly the vehicle is rotating around its longitudinal and lateral axes. This data complements accelerometer information, providing a complete picture of vehicle dynamics. High-end systems use automotive-grade gyroscopes with excellent accuracy and temperature stability.

Forward-looking cameras represent the cutting edge of sensor technology for active suspension. Mounted at the top of the windshield, these cameras scan the road ahead at distances from 15 to 50 feet, depending on vehicle speed. Image processing algorithms identify bumps, potholes, expansion joints, and other road irregularities. The system calculates when each wheel will encounter the irregularity based on vehicle speed and steering angle, then pre-adjusts the suspension appropriately. This predictive capability transforms ride quality by enabling proactive rather than reactive control.

The concept of sensor fusion proves critical—the ECU doesn’t trust any single sensor but instead combines data from multiple sources to build an accurate picture of vehicle state. If accelerometer data and height sensor data disagree, the system must determine which is correct or if both are providing partial information about a complex situation. Sophisticated algorithms handle sensor fusion, providing robust state estimation even with imperfect sensor data.

Electronic Control Unit (ECU) – The Brain

The suspension control ECU represents one of the most computationally intensive control modules in modern vehicles. It must process data from dozens of sensors, run complex control algorithms, and command actuators at each wheel—all in cycles measured in milliseconds.

Processing speed varies by system sophistication. Basic adaptive damping systems might update every 10-20 milliseconds, while advanced predictive systems can operate at 100 Hz (10 milliseconds per cycle) or faster. The faster the cycle rate, the quicker the system responds to changing conditions and the smoother the control feels.

The ECU runs multiple control algorithms simultaneously, each optimizing different aspects of suspension behavior. The primary algorithm might implement “Skyhook” theory—an idealized control strategy that attempts to connect the vehicle body to an imaginary fixed reference point in the sky, isolating it from road-induced motions. Other algorithms manage body roll during cornering, pitch during braking/acceleration, and ride height control. These algorithms must work together harmoniously, with the ECU arbitrating between competing demands.

Modern active suspension ECUs integrate with other vehicle systems through the CAN (Controller Area Network) bus. The suspension ECU receives information from the electronic stability control system, traction control, ABS, engine management, and transmission control. This integration enables coordinated behavior—for instance, when the transmission shifts, the ECU can briefly stiffen damping to minimize the pitch disturbance that power delivery changes create.

The ECU stores fault codes when it detects sensor failures, actuator malfunctions, or control algorithm errors. These diagnostic trouble codes (DTCs) prove essential for technicians diagnosing system issues. Advanced systems provide extensive diagnostic data including sensor readings, actuator commands, and control state information that professional scan tools can display. This diagnostic capability has become more sophisticated as active suspension systems have matured.

Some high-end systems incorporate machine learning algorithms that adapt to individual driver preferences over time. The system observes how the driver sets the suspension mode, correlates this with driving conditions, and gradually learns preferred settings. Eventually, the system can automatically select appropriate modes without driver input, or fine-tune the characteristics within each mode to match driver preference.

Actuators – The Muscles

Actuators convert electronic control signals into mechanical forces that adjust suspension behavior. The type and capability of actuators fundamentally determines system performance.

Hydraulic cylinders in fully active systems act as double-acting actuators that can push or pull with substantial force. These cylinders mount between the vehicle body and suspension, often replacing conventional dampers entirely. High-pressure hydraulic fluid enters one side of the piston while exiting the other, creating forces that can support vehicle weight, resist body motions, and actively move the chassis. The speed of response depends on valve technology—modern high-speed proportional valves can redirect hydraulic flow in milliseconds.

Electric motors in electromagnetic active suspension connect to the suspension through various mechanisms. Audi’s system uses rotary motors connected to torsion bars—the motor applies torque to twist the torsion bar, which then applies force to the suspension. The advantage of electric actuation is extremely fast response and the ability to recover energy during compression events. As the suspension compresses, the motor acts as a generator, converting kinetic energy into electrical energy that returns to the vehicle’s electrical system. This regenerative capability can recover 10-20% of the energy, partially offsetting the power consumption of active control.

Control valves in semi-active systems modulate hydraulic flow within dampers to vary damping force. Magnetorheological systems use electromagnetic coils to generate magnetic fields that change fluid properties. Valve-actuated systems use solenoid valves or proportional valves to adjust orifice size and therefore flow restriction. The precision and speed of these valves directly affects how smoothly and quickly damping can change.

The force capability of actuators determines how effectively the system can control vehicle motions. High-end systems can generate forces of 1,000+ Newton-meters per corner—enough to significantly influence vehicle behavior. Lesser systems might generate only enough force to firm up damping but not to actively move the chassis. This distinction separates truly active systems from simpler adaptive implementations.

Response time proves critical for active suspension performance. The faster actuators can change force output, the better the system can respond to rapid changes in road conditions or vehicle dynamics. The best systems can transition from soft to firm damping in under 10 milliseconds—faster than the suspension can complete a full oscillation cycle. This speed enables the control algorithms to implement sophisticated strategies that would be impossible with slower actuators.

Hydraulic System (Fully Active)

Fully active hydraulic suspension requires a complete high-pressure hydraulic system integrated into the vehicle. An engine-driven or electric hydraulic pump generates pressure, typically 2,000-3,000 PSI—several times higher than typical automotive hydraulic systems like power steering. The pump runs continuously during vehicle operation, maintaining pressure in the system.

High-pressure accumulators store hydraulic energy for rapid response. These gas-charged accumulators contain nitrogen separated from hydraulic fluid by a bladder or piston. When the system demands rapid fluid flow—for instance, to stiffen suspension before a corner—fluid releases from the accumulator instantly rather than waiting for the pump to deliver it. This stored energy enables the quick response characteristic of high-performance active suspension.

Pressure control valves regulate system pressure and direct fluid flow to actuators at each wheel. Modern systems use sophisticated proportional valves that can vary flow rate and pressure continuously, enabling smooth control. Emergency shutoff valves provide safety by isolating failed components and preventing total system pressure loss.

The hydraulic fluid reservoir stores fluid and allows for thermal expansion. High-pressure hydraulic systems generate considerable heat through fluid compression and valve throttling, so the reservoir may include cooling capacity. The reservoir also allows air separation—any air in the hydraulic system degrades performance by creating compressibility.

Distribution lines carry high-pressure fluid throughout the vehicle. These specialized hoses and hard lines must withstand sustained high pressure, resist abrasion, and tolerate the chemicals in hydraulic fluid. Proper installation and maintenance proves critical—a hydraulic line failure at 3,000 PSI can spray fluid considerable distances, creating safety hazards.

Filtration systems protect the precision hydraulic components from contamination. Even microscopic particles can damage valve seats and orifices, degrading control precision. Multi-stage filtration ensures fluid cleanliness, though this requires periodic filter replacement as part of system maintenance.

Electrical Power System

Active suspension’s electrical requirements vary dramatically by system type. Fully active hydraulic systems need power for the ECU, sensors, and control valves, but the hydraulic pump provides the primary power for actuation—drawn either from the engine through a belt drive or from an electric motor. Total power consumption can reach 2-5 kilowatts during active control, with peaks above 10 kilowatts during aggressive driving.

Semi-active magnetorheological systems prove far more efficient, drawing only 50-100 watts total for all four corners plus ECU and sensor power. The electromagnetic coils that control the magnetorheological fluid require minimal energy, making these systems practical even in fuel-economy-focused applications.

Electromagnetic active suspension systems use 48-volt electrical architecture to provide sufficient power for the electric actuators. Operating at 48 volts rather than the conventional 12 volts reduces current requirements by a factor of four for the same power level, enabling practical wiring sizes. The 48-volt system requires DC-DC converters to interface with conventional 12-volt vehicle electronics, adding complexity but enabling capabilities impossible at 12 volts.

The trend toward vehicle electrification makes electrical power more readily available. Mild hybrid systems with 48-volt starter-generators, and especially strong hybrid and full electric vehicles with high-voltage battery packs, can supply the power active suspension demands without significant impact on vehicle range or fuel economy. This alignment between vehicle electrification and active suspension power requirements explains why active suspension adoption is accelerating as the vehicle fleet electrifies.

The integration with components like steering knuckles, control arm bushings, and other suspension elements requires careful engineering to ensure actuators can deliver force without introducing unwanted constraints. The suspension must maintain proper geometry and kinematics while accommodating active components.

Control Strategies and Algorithms

The sophistication of control algorithms separates good active suspension from exceptional systems. These algorithms determine how sensor data translates into actuator commands.

Skyhook Theory provides the conceptual foundation for many active suspension control strategies. Imagine the vehicle suspended from an imaginary hook attached to a fixed point in the sky. If this were actually possible, the vehicle body would remain perfectly stable—when the wheels encounter bumps, they could move freely without transmitting forces to the chassis because the chassis is supported by the sky hook rather than the springs.

Obviously, an actual sky hook is impossible, but control algorithms can simulate this effect. The key insight: when the chassis moves upward (perhaps from a bump), increase damping to resist the motion, simulating resistance from the sky hook. When the chassis moves downward, reduce damping to allow the motion, again simulating the imaginary connection to a fixed reference. By measuring chassis acceleration with accelerometers and intelligently varying damping based on the direction and magnitude of motion, active suspension can approximate ideal sky hook behavior.

The mathematics behind Skyhook theory provide a practical control law: desired damping force equals damping coefficient times the absolute velocity of the chassis. When implemented properly, this creates the sensation that the vehicle body is isolated from road disturbances—exactly what sky hook suspension would provide. The beauty of this approach is its simplicity and effectiveness, which explains why variations of Skyhook theory appear in most active suspension systems.

Adaptive Damping Logic builds on Skyhook foundations but adds intelligence based on driving conditions. The system continuously calculates optimal damping coefficient based on multiple inputs: current vehicle speed, lateral and longitudinal acceleration, steering angle, throttle position, brake pressure, and selected driving mode. Each of these inputs provides information about driver intent and current vehicle dynamics.

During normal cruising, the system favors comfort with softer damping that allows the suspension to absorb road irregularities smoothly. When sensors detect aggressive driving—heavy braking, sharp steering inputs, or hard acceleration—the system transitions toward firmer damping that minimizes body motions and maintains vehicle control. This transition happens smoothly over a few hundred milliseconds, imperceptible to occupants but dramatically affecting vehicle behavior.

Different driving modes alter the balance between comfort and performance. Comfort mode biases the algorithm toward softer damping even during dynamic driving, accepting some body movement in exchange for superior ride quality. Sport mode biases toward firmer damping, minimizing body movements at the expense of transmitting more road feel to passengers. Normal or Auto mode continuously adapts, choosing settings appropriate for current conditions without requiring driver intervention.

The algorithms must handle conflicting demands intelligently. If the driver selects Sport mode but is currently driving on severely broken pavement, should the system maintain firm damping for handling or soften temporarily for comfort? Advanced systems make these decisions based on priority hierarchies and predictive logic that considers recent driving patterns.

Predictive Control represents the most advanced active suspension technology, using forward-looking sensors to prepare for upcoming road conditions. When the camera detects a bump 20 feet ahead, the system calculates which wheel will encounter it, when impact will occur based on vehicle speed, and how severe the disturbance will be based on bump size. The ECU then softens damping at the appropriate corner just before wheel contact, allowing the suspension to absorb the bump with minimal force transmission to the chassis. After the wheel passes over the bump, damping instantly increases to prevent excessive rebound.

This proactive approach transforms ride quality in ways reactive control cannot match. Reactive systems respond to bumps after the wheel impacts them—the suspension has already started compressing, transmitting force to the chassis, before the ECU can command softer damping. Predictive systems prepare before impact, completely changing the vehicle’s interaction with road irregularities.

Mercedes-Benz’s E-Active Body Control combines predictive suspension with active sway bar control and curve tilting. When the camera detects an upcoming curve (or when GPS data indicates one based on map information), the system can actually lean the vehicle into the turn like a motorcycle, counteracting lateral forces that push occupants sideways. This feature enhances comfort during spirited driving and demonstrates how active suspension can go beyond traditional suspension objectives.

The relationship between active suspension and other advanced chassis systems, including technologies covered in discussions of electronic power steering and stability control, creates integrated vehicle dynamics control. All these systems work together through the vehicle’s network, sharing data and coordinating responses to create seamless, intelligent vehicle behavior.

Safety Warning: Active suspension systems operate at high hydraulic pressures (2,000-3,000 PSI in hydraulic systems) and contain electrically powered actuators capable of generating substantial forces. Never attempt to service hydraulic components without proper depressurization procedures following manufacturer specifications. Hydraulic fluid under pressure can penetrate skin and cause serious injury—treat all hydraulic connections as potentially dangerous until verified depressurized. Electric actuators may remain energized even with the ignition off—always disconnect the battery before servicing active suspension electrical components. Improper service can result in component failure during vehicle operation, creating dangerous handling characteristics or complete loss of suspension control. Professional service with proper training, equipment, and safety procedures is absolutely essential.

How Active Suspension Operates in Real-World Driving

Understanding the theoretical operation of active suspension provides foundation, but seeing how the system responds to real-world driving situations reveals its practical benefits and intelligent behavior.

Real-Time Operation Cycle

Active suspension operates in a continuous cycle that repeats many times per second. Let’s follow one complete cycle to understand the process.

Step 1: Continuous Monitoring (Every 10-100 Milliseconds)

The cycle begins with data collection. Accelerometers throughout the vehicle measure vertical, lateral, and longitudinal acceleration. Height sensors report suspension position at each corner. Wheel speed sensors provide rotation data. The steering angle sensor indicates steering input. If the system has predictive capability, the forward-looking camera provides road surface information ahead of the vehicle.

All this sensor data flows to the suspension ECU through high-speed communication networks. The ECU must receive, validate, and process this information within the cycle time—typically 10-100 milliseconds depending on system sophistication. Faster cycle rates enable quicker responses but demand more computational power.

Step 2: State Estimation and Sensor Fusion

The ECU processes raw sensor data to determine the vehicle’s actual state. This proves more complex than simply reading sensor values because sensors can have noise, drift, and occasional errors. The ECU uses mathematical algorithms (often Kalman filters or similar estimation techniques) to combine data from multiple sensors into a best estimate of true vehicle state.

For example, body roll during cornering can be estimated from lateral accelerometer data, but also from differences in height sensor readings between left and right sides. The ECU fuses both sources to get an accurate roll estimate. If one sensor fails or provides implausible data, the system can continue operating using information from remaining sensors—this redundancy improves reliability.

Step 3: Control Algorithm Calculation

With accurate state information, the control algorithm calculates desired suspension behavior. If the vehicle is entering a turn based on steering angle input, the algorithm predicts lateral weight transfer and prepares to stiffen the outside dampers. If accelerometers detect pitch from braking, the algorithm adjusts front and rear damping to minimize nose dive. If the camera sees an upcoming bump, the algorithm prepares the appropriate corner to absorb it smoothly.

The calculation considers current driving mode (Comfort, Normal, Sport), vehicle speed, and recent driving patterns. Advanced systems might incorporate learned driver preferences or adapt to road conditions experienced in the past few seconds. The output is a specific damping force or actuator position command for each corner of the vehicle.

Step 4: Actuator Command

The ECU sends commands to actuators at each wheel. In hydraulic systems, control valves adjust to deliver calculated forces. In magnetorheological systems, the ECU varies current to electromagnetic coils, changing magnetic field strength and therefore damping force. In electromagnetic systems, the motors receive commands to push or pull with specified force.

These commands must execute within milliseconds to be effective. The best systems can transition from soft to firm damping in under 10 milliseconds—fast enough that wheel motion barely begins before the suspension characteristics change.

Step 5: Monitoring and Adaptation

The cycle doesn’t end with commanding actuators. The ECU monitors the results through sensor feedback. Did the chassis respond as predicted? Are body motions controlled appropriately? If actual behavior differs from predictions, the control algorithm adapts on the next cycle.

This continuous feedback loop enables the system to handle unexpected situations and maintain optimal control even as conditions change. The entire process then repeats—data collection, state estimation, control calculation, actuation, verification—dozens or hundreds of times per second throughout vehicle operation.

Response to Dynamic Events

Active suspension’s real-world benefits become apparent during specific driving events that challenge vehicle dynamics.

Cornering creates lateral weight transfer—the outside wheels compress while inside wheels extend as the vehicle leans outward. In passive suspension, this body roll reaches 10-20 degrees during aggressive cornering, pushing occupants uncomfortably sideways and reducing tire contact effectiveness on the inside wheels. Active suspension detects the turn from steering angle and lateral acceleration, then instantly stiffens the outside dampers while maintaining or softening inside damping. This asymmetric control reduces body roll to 2-5 degrees while maintaining tire contact and improving comfort. The vehicle feels planted and precise, responding crisply to steering inputs rather than wallowing through corners.

Braking causes forward weight transfer as the vehicle’s momentum tries to rotate it around the front wheels—the nose dives while the rear rises. This pitch reduces rear brake effectiveness and can create instability, especially during aggressive braking. Active suspension detects braking from deceleration sensors and brake pressure signals, then stiffens front damping while adjusting rear damping to maintain a level platform. The vehicle remains flat during braking, maintaining optimal weight distribution and improving both braking performance and occupant comfort. Emergency braking benefits particularly from this control—the vehicle remains stable and controllable rather than pitching dramatically.

Acceleration creates opposite weight transfer—rearward momentum tries to rotate the vehicle around the rear wheels, lifting the front and squatting the rear. This reduces front tire contact and can cause wheel spin on powerful vehicles. Active suspension counters this by stiffening rear damping and adjusting front damping to minimize squat. Performance vehicles benefit especially—keeping the rear planted during hard acceleration maximizes traction while maintaining steering control.

Bumps and Road Irregularities represent the most common suspension challenge. When a wheel encounters a bump, passive suspension transmits much of the impact to the chassis before the damper can control rebound oscillation. Active suspension can detect the bump impact and instantly soften damping, allowing the wheel to move freely over the obstacle without significant force transmission. Once the wheel clears the bump and begins to rebound, damping instantly increases to prevent the bounce that would otherwise occur. This selective damping dramatically improves ride quality, making the vehicle glide over road imperfections that would jar passengers in conventional suspension.

Potholes require even more sophisticated control. When a wheel drops into a pothole, the suspension extends rapidly. Active suspension softens extension damping to allow the wheel to drop freely, minimizing the jarring impact when the wheel hits the bottom of the pothole. Then, as the wheel exits the pothole and suspension compresses, damping increases to control the compression and prevent harsh bottom-out. The result feels almost like the pothole wasn’t there—occupants barely notice road irregularities that would be severe impacts in passive suspension.

Driver-Selectable Modes

Most active suspension systems provide driver-selectable modes that alter suspension behavior to match preferences and driving conditions. Understanding these modes helps drivers optimize their vehicle for specific situations.

Comfort Mode prioritizes ride quality above all else. The system uses the softest damping settings appropriate for current speed and road conditions, allowing the suspension to absorb bumps and irregularities smoothly. Body movements are permitted within reasonable limits—the vehicle may lean during cornering or pitch during braking more than in firmer modes, but the trade-off delivers exceptional isolation from road imperfections.

Comfort mode proves ideal for highway cruising, urban driving on rough pavement, or any situation where passenger comfort takes priority over dynamic performance. Long-distance driving benefits particularly—the reduced transmission of small, frequent road irregularities significantly reduces fatigue over hours. Passengers with motion sensitivity often prefer Comfort mode because the softer damping creates gentler, more gradual body movements rather than the abrupt responses of firmer settings.

However, Comfort mode can feel vague during aggressive driving. The softer damping allows more body roll in corners and pitch during braking, creating a disconnected feeling where the vehicle’s responses lag behind driver inputs. Enthusiastic drivers generally prefer firmer modes that provide more immediate feedback and control.

Normal or Auto Mode provides balanced damping that adapts continuously to driving conditions. The system monitors driver inputs—steering angle, throttle position, brake pressure—and adjusts damping to match apparent driving style. During gentle cruising, Normal mode behaves much like Comfort, providing smooth ride quality. When the driver accelerates hard, brakes firmly, or turns sharply, the system instantly firms up to provide better control.

This adaptive behavior makes Normal mode versatile for varied driving. The system handles the optimization automatically, eliminating the need for manual mode selection. Most drivers leave their active suspension in Normal/Auto mode and let the system decide appropriate settings. The intelligence built into modern adaptive algorithms means Auto mode delivers near-optimal performance across a wide range of conditions.

Advanced systems learn driver preferences over time in Auto mode. If a particular driver consistently selects Sport mode, the system gradually biases Auto mode toward firmer settings even when nominally in Normal. This personalization happens transparently, adapting the vehicle to the individual without requiring explicit customization.

Sport or Dynamic Mode maximizes handling performance through the firmest damping settings. The system minimizes body roll, pitch, and vertical motions, creating a taut, responsive feel where the vehicle reacts instantly to driver inputs. Steering feels more direct because the chassis remains stable rather than shifting weight around. Cornering speeds increase because body roll remains minimal and tire contact is optimized.

The trade-off is reduced comfort—firmer damping transmits more road texture to passengers. Bumps and irregularities that would be barely noticeable in Comfort mode become clear in Sport. For smooth roads and enthusiastic driving, Sport mode transforms the vehicle’s character, making it feel smaller, lighter, and more agile. For rough roads or relaxed driving, Sport mode can feel harsh and jarring.

Many vehicles offer multiple Sport modes with progressively firmer settings. Sport might provide slightly firmer damping than Normal, while Sport Plus or Track mode delivers maximum firmness for circuit driving. These variations let drivers fine-tune the balance between comfort and performance.

Individual or Custom Mode allows drivers to configure specific parameters independently. A driver might select soft damping for ride comfort but firm sway bar control for reduced body roll, creating a custom combination unavailable in preset modes. Or they might combine comfort suspension with sport steering and throttle response. The system saves these preferences in vehicle memory, often linking them to specific driver profiles accessed through key fobs or driver recognition systems.

Custom modes demonstrate the sophistication of modern vehicle integration. Suspension settings coordinate with steering effort, throttle mapping, transmission shift points, stability control intervention levels, and exhaust sound tuning to create coherent, customizable driving experiences. This holistic approach to vehicle dynamics control represents a major advance in automotive engineering.

The integration with different suspension architectures varies by design. Double wishbone systems provide excellent geometry for active components, while simpler torsion beam designs in the rear of many vehicles can also incorporate adaptive damping. The suspension architecture must accommodate active components while maintaining proper kinematics and geometry.

Advanced Features in Modern Systems

The latest active suspension systems incorporate features that extend beyond traditional suspension objectives, demonstrating the technology’s versatility and potential.

Auto-Leveling maintains consistent ride height regardless of load. When passengers or cargo are added, passive suspension compresses under the additional weight, lowering ride height and potentially causing the vehicle to bottom out over bumps. Active systems with ride height control—typically air suspension or fully active hydraulic systems—detect the load increase through height sensors and automatically adjust spring rate or ride height to compensate.

This proves particularly valuable in SUVs and trucks that frequently operate with varying loads. An unloaded truck sits high with soft ride quality, while the same truck loaded with cargo or towing a trailer sags and rides harshly. Auto-leveling maintains consistent geometry, ground clearance, and ride characteristics regardless of load. The headlight aim remains correct, preventing the dangerous upward-aimed beams that occur when a loaded vehicle’s rear sags. Trailer towing benefits especially—maintaining level ride height improves trailer stability and reduces sway.

Active Sway Bar Control represents an advanced feature that enhances both on-road handling and off-road capability. Traditional anti-roll bars connect left and right suspension to resist body roll—when one side compresses, the bar forces the other side to compress equally, minimizing the difference and therefore reducing lean. However, this connection also restricts independent wheel movement, reducing suspension articulation when one wheel encounters an obstacle.

Active sway bars solve this compromise by disconnecting the bar when maximum articulation is needed (off-road driving, loading uneven surfaces) and connecting or actively stiffening it when body roll control is important (on-road cornering). The system can disconnect the front bar for rock crawling, allowing dramatic wheel travel, then instantly reconnect and stiffen it when returning to pavement. Some systems use electric or hydraulic actuators to actively twist the sway bar, providing roll control beyond what passive bars can achieve.

Curve Tilting (Mercedes Active Curve Tilting) represents one of the most innovative active suspension features. Rather than resisting body roll during cornering, the system intentionally leans the vehicle into the turn like a motorcycle. This counterintuitive approach actually enhances comfort by reducing the lateral forces occupants feel—when the vehicle leans into a turn at the same angle as the lateral force vector, occupants feel pushed into their seats rather than sideways.

The system uses accelerometers to measure lateral acceleration and steering angle to predict cornering forces. Hydraulic actuators then actively tilt the vehicle body inward. The tilt angle adjusts continuously based on cornering forces—gentle turns create slight tilt, while aggressive cornering can produce 2-3 degrees of inward lean. The effect feels natural rather than artificial, similar to how humans naturally lean when walking around a curve. High-speed sweeping turns become noticeably more comfortable because side forces are redirected into seat back pressure rather than lateral sliding.

Beginner Note: Think of active suspension modes like having different vehicles in one package. Comfort mode feels like a luxury sedan floating over bumps. Sport mode feels like a sports car, firm and responsive. Normal mode is like a well-balanced daily driver. The system switches between these “personalities” either automatically based on how you’re driving, or manually when you select a different mode. It’s the closest thing to magic in modern automotive engineering—one vehicle that genuinely adapts to provide whatever you need at the moment.

Active Suspension Applications: From Luxury Cars to Electric Vehicles

Active suspension has evolved from exotic racing technology to a production feature found across multiple vehicle segments. Understanding current applications and future developments reveals where this technology is heading and why it matters increasingly in modern automotive engineering.

Current Production Systems

Luxury Vehicles showcase active suspension’s most advanced implementations, where cost considerations take secondary priority to delivering ultimate comfort and performance.

Mercedes-Benz pioneered production active suspension with Active Body Control (ABC) in 1999, originally appearing on the CL coupe and S-Class sedan. The system evolved through several generations, culminating in E-Active Body Control featuring curve tilting and road scanning. The stereo camera mounted at the windshield top scans the road ahead up to 50 feet, identifying bumps, potholes, and surface irregularities. The system calculates which wheel will encounter each irregularity, when impact will occur based on vehicle speed, and how severe it will be. The hydraulic actuators then prepare that corner appropriately—softening for bumps, stiffening for optimal support.

Magic Body Control in the S-Class represents Mercedes’ ultimate suspension technology. Combined with 48-volt electrical architecture and E-Active Body Control, the system can adjust each wheel independently within milliseconds. The result approaches the smoothness of rail transport—passengers barely notice road conditions that would be jarring in conventional vehicles. The system integrates with navigation data, using GPS information about upcoming curves to prepare the suspension before the turn even begins.

Audi developed a different approach with their Predictive Active Suspension introduced in 2017. Rather than hydraulics, Audi uses electromechanical actuators—electric motors connected through reduction gears to rotary tubes with internal titanium torsion bars. Each actuator can generate up to 1,100 Newton-meters of torque, actively lifting or lowering individual corners. The 48-volt electrical system provides power, and like Mercedes, a forward camera scans the road to enable predictive control. The electric approach offers extremely fast response and regenerative capability—when suspension compresses, the motors act as generators, recovering energy that would otherwise be wasted.

BMW’s Adaptive M Suspension and Electronic Damping Control provide similar capabilities with different execution. The systems use electronically controlled dampers with driver-selectable modes and automatic adaptation to driving conditions. Integration with BMW’s overall vehicle dynamics control creates cohesive behavior across suspension, steering, and powertrain.

Rolls-Royce developed the Flagbearer system for the Phantom and Ghost, combining adaptive air suspension with forward-looking cameras. The “magic carpet ride” Rolls-Royce promises customers relies heavily on this technology—the air suspension provides variable ride height and spring rates, while the camera-based system anticipates and prepares for road irregularities. The result is transportation that insulates occupants from the outside world to an unprecedented degree.

Genesis, Hyundai’s luxury brand, offers Road Preview suspension in flagship models. The system uses GPS data from the navigation system combined with camera scanning to prepare for road conditions. When approaching a known rough section of road, the system proactively adjusts suspension settings. This demonstrates how active suspension benefits from vehicle connectivity and available digital information.

Performance Applications use active suspension to enhance track capability while maintaining street driveability—the ultimate dual-purpose optimization.

Ferrari equipped vehicles like the 488 GTB and F8 Tributo with magnetorheological dampers that adjust in milliseconds, creating remarkably versatile suspension behavior. The system integrates with Ferrari’s electronic differential and stability control, creating a cohesive vehicle dynamics package. On track, the suspension remains firm enough to maintain precise body control through high-speed corners. On the street, the same vehicle provides surprisingly comfortable transportation. The ability to transition between these extremes at the touch of a button transforms Ferrari’s usability.

Porsche Active Suspension Management (PASM) appears across the model range from Cayenne SUVs to 911 sports cars. The continuously variable damping system adapts to driving style and road conditions, providing the versatility Porsche owners expect. Track-focused models add more aggressive calibrations while maintaining daily driveability.

The Corvette’s Magnetic Ride Control uses magnetorheological dampers similar to Ferrari’s implementation. The capability to adjust damping based on road conditions and driving mode makes the Corvette simultaneously an effective track car and comfortable grand tourer—versatility that would be impossible with passive suspension.

Electric Vehicles benefit particularly from active suspension because battery packs create unique challenges and opportunities for chassis engineering.

Tesla Model S and Model X use Adaptive Air Suspension to manage the weight and low center of gravity created by floor-mounted battery packs. The system can lower the vehicle at highway speeds to reduce aerodynamic drag—this contributes meaningfully to range, as aerodynamic efficiency becomes increasingly important at highway speeds. Tesla’s implementation also provides auto-leveling when loaded and driver-selectable ride height for varying conditions.

Lucid Air combines air springs with active dampers to manage the substantial weight of its large battery pack while delivering the luxury ride quality appropriate for the vehicle’s market positioning. The system adjusts ride height based on speed and can lower further when in parking mode to ease entry and exit.

Mercedes EQS, the electric flagship sedan, uses E-Active Body Control similar to the S-Class implementation but optimized for the EQS’s electric powertrain and battery weight distribution. The system helps manage the unique dynamics of a heavy electric vehicle while maximizing comfort and efficiency.

Audi’s e-tron electric SUV uses Adaptive Air Suspension Sport with electronically controlled damping. The ability to adjust ride height proves valuable in an SUV—higher for off-road or rough road use, lower for improved aerodynamics and efficiency on highways. The system demonstrates how active suspension functionality expands beyond traditional ride and handling to include efficiency optimization.

EV-specific benefits include battery weight distribution management—the low-mounted, heavy battery creates unusual weight distribution that active suspension can optimize. The instant torque characteristic of electric motors creates different suspension demands than conventional engines—active suspension can counter the weight transfer from instant acceleration more effectively than passive systems. Energy efficiency improvements through aerodynamic ride height adjustment contribute to the range anxiety challenge, making active suspension not just a luxury feature but a practical efficiency enhancement.

Integration with Autonomous Driving

Active suspension’s role expands significantly in autonomous vehicles because passengers rather than drivers become the primary consideration. When no one is driving, minimizing motion sickness and maximizing comfort become paramount objectives.

Predictive algorithms using GPS map data can prepare suspension for upcoming road conditions even before cameras can see them. If the navigation system knows the vehicle will encounter rough pavement in 500 feet, the suspension can transition to comfort mode proactively. On highways with extensive mapping data, the system might know about expansion joints, bridge transitions, and pavement quality changes, preparing suspension appropriately.

Vehicle-to-vehicle (V2V) communication enables even more advanced predictive capability. If vehicles share information about road conditions they’ve encountered, following vehicles can prepare suspension before reaching those locations. A pothole that the first vehicle in a group encounters and shares information about allows all following vehicles to prepare appropriately—essentially creating crowdsourced road condition mapping in real-time.

Coordination with autonomous braking and acceleration systems becomes critical. When the autonomous system decides to brake, it can simultaneously command suspension to stiffen and prevent pitch. When accelerating from a stop, suspension coordination minimizes squat. This integration creates smoother, more controlled autonomous driving behavior.

The lack of driver control inputs changes how suspension modes work. In manually driven vehicles, steering angle and throttle position indicate driver intent. In autonomous vehicles, the driving system knows its intentions and can command suspension appropriately. The suspension can prepare for lane changes, anticipate merges, and optimize for planned acceleration or braking—coordination impossible when a human driver’s thoughts aren’t accessible to vehicle systems.

Future Technology Developments

Active suspension continues evolving with developments that promise even better performance, lower cost, and expanded capabilities.

Artificial Intelligence and Machine Learning enable suspension systems that genuinely learn and adapt. Current systems follow pre-programmed algorithms that respond to sensor inputs according to fixed rules. AI-powered systems can learn individual driver preferences over thousands of miles, gradually customizing behavior to match how each driver responds to different suspension characteristics.

The system might learn that a particular driver prefers firmer damping during morning commutes but softer settings when driving in the evening. Or it might recognize that this driver consistently prefers comfort mode on certain roads but sport mode on others, and automatically select appropriately. Pattern recognition algorithms can predict driver behavior based on historical data—if the driver typically accelerates hard after certain intersections, the suspension can prepare by stiffening slightly.

Route-based learning proves particularly promising. If the vehicle frequently travels certain routes, the system can learn where rough pavement sections exist, where tight corners require firmer suspension, and where smooth sections allow maximum comfort. This creates a customized suspension map for regular routes without requiring explicit programming or mapping data.

Advanced Actuation Technology focuses on improving efficiency, response time, and cost. More efficient electromagnetic actuators that draw less power while generating greater force would reduce the efficiency penalty active suspension imposes. Current electromagnetic systems consume several hundred watts continuously—reducing this to 100 watts or less would make the technology practical even in efficiency-focused applications.

Faster response times approaching sub-millisecond actuation would enable control strategies impossible with current technology. Some theoretical control approaches require extremely rapid force changes to implement optimally—faster actuators would unlock these capabilities.

Regenerative energy capture remains an area for improvement. Current electromagnetic systems can recover 10-20% of compression energy—advancing this to 30-40% would significantly reduce net power consumption. Sophisticated power electronics and motor control algorithms can optimize regenerative operation, potentially making electromagnetic active suspension energy-neutral or even energy-positive in certain driving conditions.

Connected Vehicle Technology transforms active suspension from a isolated chassis system to one integrated with broader infrastructure and vehicle networks. Cloud-based road condition databases can provide detailed information about pavement quality, known potholes, expansion joints, and speed bumps. As vehicles encounter and report road conditions, the database continuously updates, providing increasingly accurate information to all connected vehicles.

Real-time traffic and road quality updates enable proactive suspension optimization. If traffic apps indicate congestion ahead, the suspension can transition to comfort mode for the anticipated stop-and-go driving. If accident or construction creates rough detours, suspension prepares accordingly.

Vehicle-to-infrastructure (V2I) communication might enable even more sophisticated coordination. Traffic signals could inform approaching vehicles when they’ll change, allowing suspension to prepare for stopping or accelerating. Construction zones could broadcast their locations and surface conditions, giving suspension systems advance warning.

Predictive maintenance becomes more effective with connectivity. The suspension ECU monitors actuator response, sensor health, and system behavior continuously. When degradation is detected—perhaps dampers responding slightly slower than when new—the system can predict remaining service life and alert the driver to schedule maintenance before failure occurs. Cloud connectivity allows manufacturers to monitor entire fleets, identifying common failure modes and developing improved components or software updates to prevent issues.

Cost Reduction Trends will expand active suspension’s availability beyond luxury and performance vehicles. Technology always becomes more affordable with volume production and engineering refinement. What was exclusive to $100,000+ vehicles a decade ago now appears on $50,000 vehicles. The next decade will likely bring semi-active adaptive suspension to $30,000 vehicles as technology matures and manufacturing costs decline.

Simplified semi-active systems providing core functionality without exotic features offer a path to broader adoption. Not every implementation needs predictive cameras, curve tilting, or independent height control at each corner. A basic system providing driver-selectable comfort and sport modes with automatic adaptation would deliver significant benefits at modest cost increase over passive suspension.

Integration with existing electronic architecture reduces incremental cost. As 48-volt electrical systems become standard for mild hybrid functionality, the infrastructure exists for more sophisticated suspension without requiring dedicated electrical systems. As processing power increases in vehicle controllers, adding suspension algorithms to existing ECUs rather than requiring dedicated suspension computers reduces cost.

Manufacturing scale drives costs down through typical economies of scale. As more vehicles use magnetorheological dampers, for instance, production volumes increase and unit costs decrease. Suppliers develop more cost-effective manufacturing processes and design refinements that maintain performance while reducing complexity.

The technology trickle-down effect that has characterized automotive innovation continues—active suspension will follow the path of anti-lock brakes, stability control, and adaptive cruise control from expensive luxury features to mainstream standard equipment. The timeline depends on regulatory pressure, consumer demand, and engineering progress, but the direction seems clear.

For brand-specific information on active suspension implementations, see manufacturer resources for Mercedes-Benz, Audi, and BMW. Related suspension technologies including bump stops and wheel bearings integrate with active systems to create complete suspension assemblies.

Active Suspension Service Requirements and When to Seek Professional Help

Active suspension systems represent some of the most sophisticated and complex components in modern vehicles. Understanding system location, service requirements, and when professional help is essential protects both your safety and your significant investment in this advanced technology.

System Component Locations

Active suspension components are distributed throughout the vehicle, from the engine bay to each wheel corner. Knowing where components are located helps you understand the system’s scope and complexity.