Ever felt that unsettling lurch when changing gears, or heard a strange grinding noise as you press the clutch? These could be tell-tale signs of a failing clutch, a critical component in your manual transmission vehicle. Understanding how your clutch works and recognizing the early warnings can save you from costly repairs and unexpected breakdowns. Dive into our comprehensive guide to diagnosing clutch problems and learn how to keep your ride running smoothly.

What is a Clutch and Why It Matters

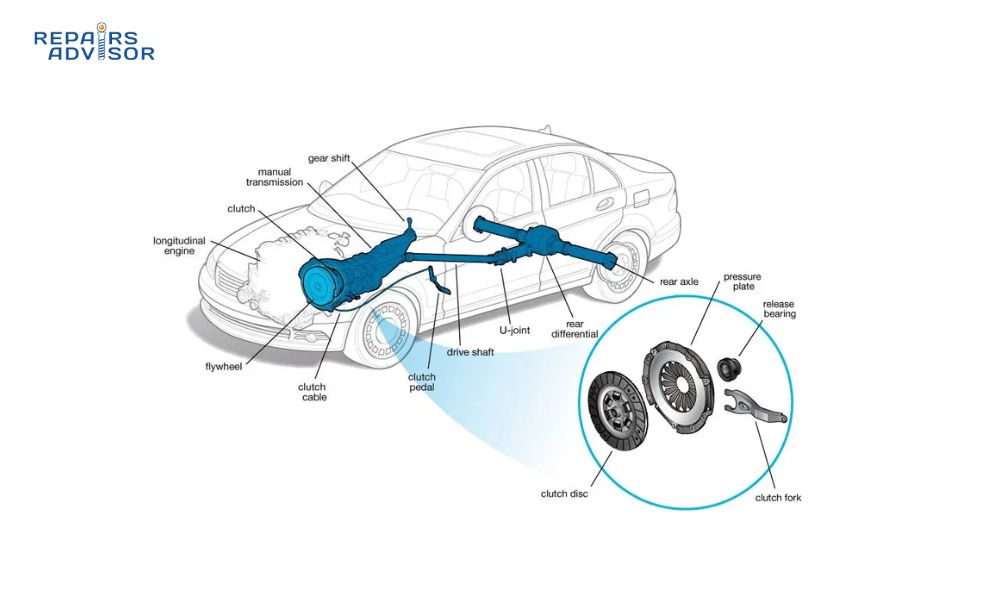

Your vehicle’s clutch serves as the critical mechanical connection between your engine and transmission, controlling when and how power flows from your running engine to the wheels that move your vehicle. This sophisticated system allows you to smoothly shift gears, come to a complete stop without stalling, and precisely control power delivery during acceleration.

In manual transmission vehicles, the clutch operates through a friction-based mechanism that can engage (connect) or disengage (disconnect) the engine from the transmission. When you press the clutch pedal, you’re temporarily breaking this connection, allowing the transmission to shift gears without grinding or damage. Release the pedal, and the connection is restored, transferring engine power to move your vehicle forward or backward.

The consequences of clutch failure extend far beyond inconvenience. A failed clutch can leave you stranded in traffic, unable to shift gears or move your vehicle safely. More critically, a partially failed clutch can create unpredictable vehicle behavior, making it difficult to accelerate when needed for safety – such as when merging onto highways or navigating emergency situations.

Modern clutches typically last between 60,000 and 100,000 miles under normal driving conditions, but this lifespan can vary dramatically based on driving habits, vehicle type, and maintenance practices. Understanding your clutch system empowers you to recognize early warning signs, make informed repair decisions, and potentially extend its operational life through proper driving techniques.

This comprehensive guide covers everything you need to know about clutch systems, from basic operation principles to advanced diagnostic procedures. Whether you’re a DIY enthusiast looking to understand your vehicle better or a professional technician seeking detailed reference information, you’ll find practical guidance for recognizing problems, understanding repair costs, and determining when professional intervention is essential for safety and reliability.

How Your Clutch Works: Technical Fundamentals

Basic Operating Principle

Your clutch operates on a fundamentally simple principle: controlled friction between rotating surfaces. The system creates a physical connection between your engine’s flywheel (which spins whenever the engine runs) and your transmission’s input shaft (which needs to spin at different speeds for different gears).

When the clutch is engaged (your foot off the pedal), spring pressure forces a friction disc tightly against the engine’s flywheel. This creates enough friction to transfer the engine’s rotational power through the disc to the transmission input shaft. The result is synchronized rotation – engine, clutch disc, and transmission input shaft all spinning together at the same speed.

The engagement and disengagement process requires precise timing and control. When you press the clutch pedal, you’re overcoming spring pressure to separate the friction disc from the flywheel. This breaks the power connection, allowing the transmission input shaft to slow down or stop while the engine continues running. During this brief disconnection, you can shift gears without forcing rotating components to suddenly match different speeds.

The Complete Operating Cycle

Understanding the complete clutch cycle helps explain why proper technique is crucial for longevity. In the engaged position (pedal released), the clutch disc is firmly clamped between the flywheel and pressure plate, creating a solid mechanical connection. All rotational force from the engine transfers through this friction contact to move your vehicle.

During disengagement (pedal pressed), the release bearing pushes against the pressure plate’s diaphragm spring fingers, pulling the pressure plate away from the clutch disc. This creates a gap that allows the disc to spin freely without contact, interrupting power flow. The engine continues running at whatever RPM you maintain with the throttle, while the transmission input shaft gradually slows down.

The gear change window occurs during full disengagement, when transmission components can move without grinding or forced synchronization. Modern transmissions include synchronizers to help match gear speeds, but the clutch must be fully disengaged for smooth operation.

Re-engagement requires skill and sensitivity. As you gradually release the clutch pedal, spring pressure begins pushing the pressure plate back toward the flywheel. The friction disc starts making contact, creating a brief period of controlled slipping where engine and transmission speeds gradually synchronize. This “friction zone” allows smooth acceleration without sudden jolts that could damage drivetrain components.

System Integration

Your clutch system doesn’t operate in isolation – it’s integrated with multiple vehicle systems that affect its performance and longevity. Engine connection occurs through the flywheel, which is bolted directly to the engine’s crankshaft. The flywheel serves multiple purposes: storing rotational energy to smooth engine power pulses, providing the starter motor engagement surface, and creating the primary friction surface for clutch operation.

Transmission interface happens through the splined input shaft, which slides through the center of the clutch disc. These splines must match precisely for proper engagement, and any wear or damage can cause engagement problems or noise. The input shaft also supports the pilot bearing or bushing, which centers the shaft in the flywheel and supports it during clutch disengagement.

Hydraulic or mechanical control systems translate your foot pressure on the clutch pedal into the force needed to operate the release bearing. Hydraulic systems use brake fluid pressure to multiply your pedal force, while mechanical systems use cables and levers. Both systems require proper adjustment and maintenance for optimal clutch feel and operation.

Driver control ultimately determines clutch life and performance. The pedal provides feedback about engagement point, spring pressure, and system condition. Changes in pedal feel often indicate developing problems, making it crucial to pay attention to how your clutch responds during normal operation.

Clutch Components: Anatomy of the System

Primary Components

Flywheel: The Foundation of Power Transfer

The flywheel serves as your clutch system’s foundation, bolted directly to your engine’s crankshaft and spinning at engine RPM whenever the motor runs. This heavy steel or cast iron disc stores rotational energy, smoothing out the power pulses created by individual cylinder firings and providing consistent rotational force for clutch engagement.

Modern vehicles may use dual mass flywheels (DMF) featuring two sections connected by springs and dampening mechanisms. These advanced designs reduce vibration transmission to the drivetrain and provide smoother engagement, but they’re more complex and expensive to replace when problems develop.

Common flywheel problems include overheating, warping, and surface damage. Excessive heat from clutch slipping can create hot spots, warping the flywheel surface and causing vibration or chatter during engagement. Deep scoring or grooving occurs when clutch friction material wears completely away, allowing metal-to-metal contact. During clutch replacement, professional inspection determines whether flywheel machining or replacement is necessary.

Inspection criteria focus on surface condition and dimensional accuracy. Machinists measure flywheel thickness, runout (wobble), and surface finish to determine if restoration is possible. Minor surface imperfections can often be machined away, but severely damaged or thin flywheels require replacement to ensure proper clutch operation.

Clutch Disc: The Critical Friction Interface

The clutch disc creates the friction connection between your engine and transmission, consisting of high-friction material bonded to a steel backing plate with a splined center hub. This friction material, similar to brake pad material, must withstand extreme temperatures and pressures while providing consistent grip characteristics.

Torsional damper springs mounted in the disc hub absorb shock loads and vibrations during engagement, protecting drivetrain components from sudden torque changes. These springs allow slight rotational movement between the friction disc and splined hub, smoothing power delivery and reducing gear noise.

The splined hub connects to your transmission’s input shaft, transferring rotational force from the friction disc to the transmission. These splines must fit precisely – too loose causes rattling and wear, while too tight creates binding and difficult engagement. Spline wear typically requires disc replacement, as proper fit is critical for smooth operation.

Wear indicators help determine replacement timing. Most clutch discs include wear specifications for minimum friction material thickness. Visual inspection reveals material condition, spring wear, and oil contamination that affects performance. Professional mechanics measure remaining material thickness and assess spring condition to determine if replacement is necessary.

Replacement criteria depend on material thickness and overall condition. Worn friction material, damaged springs, oil contamination, or spline wear all indicate replacement necessity. Attempting to extend operation beyond recommended limits risks sudden failure and potential damage to other expensive components like the flywheel or pressure plate.

Pressure Plate Assembly: The Clamping Mechanism

The pressure plate assembly provides the spring force necessary to clamp the clutch disc against the flywheel, creating the friction contact needed for power transfer. The diaphragm spring design used in modern vehicles provides consistent clamping force while requiring relatively light pedal effort for disengagement.

The cover plate protects internal components while bolting to the flywheel, ensuring the pressure plate rotates with the engine. This steel housing must withstand significant centrifugal forces while maintaining precise dimensional relationships between all internal components.

Release fingers provide the contact surface for the release bearing, allowing pedal input to overcome spring pressure and lift the pressure plate away from the clutch disc. These fingers must maintain proper height and alignment for even release bearing contact and smooth disengagement.

The clamping mechanism distributes force evenly across the clutch disc surface, ensuring consistent friction contact without hot spots or uneven wear. Proper force distribution depends on precise manufacturing tolerances and correct installation procedures.

Common failure modes include spring fatigue, finger wear, and housing cracks. Spring fatigue reduces clamping force, causing clutch slippage under load. Worn release fingers create uneven disengagement and may cause release bearing failure. Cracked housings allow contamination and may cause sudden failure, making immediate replacement necessary.

Release Bearing: The Motion Translator

The release bearing translates the linear motion from your clutch pedal into rotational force against the spinning pressure plate fingers. This specialized bearing must handle both thrust loads and rotational speeds while providing smooth, consistent operation throughout the clutch’s service life.

Ball or roller bearing construction provides low-friction rotation while handling the significant thrust loads created during clutch operation. The bearing must operate smoothly at engine RPM while withstanding the heat generated by friction and engine operation.

Hydraulic versus mechanical actuation affects bearing design and operation. Hydraulic systems typically provide more consistent force and require less maintenance, while mechanical systems offer simpler construction but need periodic adjustment for proper operation.

Common failures include bearing noise, seizure, and premature wear. A noisy release bearing creates squealing or grinding sounds when the clutch pedal is pressed, indicating imminent failure. Seized bearings make clutch disengagement difficult or impossible, while worn bearings may cause inconsistent pedal feel or incomplete disengagement.

Diagnosis relies on sound identification and pedal feel assessment. Experienced technicians can isolate release bearing noise by operating the clutch pedal while listening for specific sound patterns. Pedal feel changes, such as increased effort or inconsistent engagement point, also indicate potential release bearing problems.

Secondary Components

Clutch Master Cylinder: Hydraulic Control Center

The clutch master cylinder converts mechanical force from your clutch pedal into hydraulic pressure, multiplying your foot pressure to provide sufficient force for clutch operation. This brake-fluid-filled system operates similarly to brake master cylinders, using fluid pressure to transmit force through lines to the slave cylinder.

The piston and reservoir assembly must maintain proper fluid levels and pressure while preventing contamination that could affect system operation. The reservoir typically connects to the brake fluid reservoir or operates independently, depending on vehicle design.

Common problems include internal leaks, seal failure, and contamination. Internal seal wear allows fluid to bypass the piston, reducing available pressure and causing soft or spongy pedal feel. External leaks create fluid loss and eventual system failure, while contamination can damage seals and cause erratic operation.

Maintenance involves fluid replacement and system bleeding to remove air bubbles that compress under pressure and reduce system effectiveness. Professional service includes seal inspection and replacement when necessary to maintain proper system operation.

Clutch Slave Cylinder: Force Application Point

The slave cylinder receives hydraulic pressure from the master cylinder and converts it back into mechanical force to operate the release bearing and pressure plate. Force transmission occurs through a piston that connects to the release fork, multiplying hydraulic pressure into sufficient mechanical force for clutch disengagement.

Internal versus external mounting configurations affect accessibility and service procedures. Internal slave cylinders mount inside the transmission bellhousing, requiring transmission removal for service, while external units bolt to the outside of the bellhousing for easier access.

Release fork connection provides the mechanical link between hydraulic pressure and clutch operation. This connection must operate smoothly without binding while withstanding the forces required for clutch disengagement throughout the system’s service life.

Failure symptoms include pedal travel issues and engagement problems. A failed slave cylinder may cause the clutch pedal to sink to the floor without providing disengagement, or create inconsistent engagement that makes smooth shifting difficult. Fluid leaks around the slave cylinder indicate seal failure requiring replacement.

Pilot Bearing/Bushing: Input Shaft Support

The pilot bearing or bushing supports the transmission input shaft at its connection point with the flywheel, maintaining proper alignment during clutch engagement and disengagement. This small but critical component centers the input shaft in the flywheel and prevents vibration that could cause premature wear or noise.

Located in the center of the flywheel assembly, the pilot bearing operates in a challenging environment with limited lubrication and exposure to clutch dust and debris. Proper lubrication is essential for longevity, and contamination can cause rapid failure.

Common issues include dry operation, excessive wear, and noise generation. Inadequate lubrication causes the bearing to overheat and seize, while contamination accelerates wear and creates noise during operation. Failed pilot bearings often cause transmission input shaft vibration and may make shifting difficult.

Replacement timing typically coincides with clutch service since accessing the pilot bearing requires transmission removal. Professional mechanics routinely replace pilot bearings during clutch replacement to prevent future problems and avoid repeat transmission removal.

Recognizing Clutch Problems: Symptoms and Diagnosis

Primary Failure Modes

Clutch Slipping: When Power Doesn’t Reach the Wheels

Clutch slipping manifests as engine RPM increasing without corresponding vehicle acceleration, creating a disconnect between engine speed and actual movement. You’ll notice this most dramatically during acceleration, when pressing the throttle causes engine speed to rise rapidly while the vehicle accelerates slowly or not at all.

The underlying causes vary but center on insufficient friction between the clutch disc and flywheel. Worn friction material reduces the surface area available for grip, while oil contamination creates a slippery interface that prevents proper engagement. Weak pressure plate springs fail to provide adequate clamping force, and warped components prevent full surface contact.

Slipping typically develops progressively, starting with minor slip under heavy acceleration and gradually worsening until normal driving becomes affected. Early stages may only be noticeable when climbing hills or accelerating aggressively, but advanced slipping affects even gentle acceleration and may prevent normal highway driving.

Professional testing involves controlled load application while monitoring engine RPM and vehicle speed. Technicians may perform parking brake tests or hill start procedures to isolate slipping under known load conditions. These tests help determine slip severity and guide repair recommendations.

The urgency level ranges from moderate to high depending on slip severity. Continued driving with a slipping clutch generates excessive heat, potentially damaging the flywheel and requiring more expensive repairs. Early intervention when slipping first appears can often prevent additional component damage and reduce overall repair costs.

Clutch Dragging: When Disengagement Fails

Clutch dragging occurs when the system fails to fully disengage, leaving partial connection between engine and transmission even with the clutch pedal fully pressed. This condition makes gear shifting difficult or impossible and often produces grinding noises as transmission synchronizers struggle to match rotating speeds.

Root causes include hydraulic system problems, warped or damaged components, and improper adjustment. Low hydraulic fluid, air in the system, or failed cylinders prevent complete disengagement. Warped pressure plates or flywheels maintain partial contact even when the release mechanism operates correctly. Cable stretch or improper adjustment in mechanical systems can limit disengagement travel.

Safety implications extend beyond difficult shifting to potential transmission damage and unsafe vehicle operation. Forced shifting with a dragging clutch damages transmission synchronizers and gear teeth, while incomplete disengagement can cause the vehicle to creep forward even with the clutch pedal pressed and transmission in gear.

Emergency procedures for clutch dragging include engine-off shifting techniques where you turn off the engine, shift to the desired gear, then restart. This approach works for emergency situations but shouldn’t be used routinely as it stresses the starter and transmission components.

Professional intervention becomes essential when dragging prevents safe vehicle operation. Attempting to drive with severe dragging risks transmission damage that can cost significantly more than clutch repair, making prompt diagnosis and repair crucial for both safety and economic reasons.

Secondary Symptoms

Pedal Feel Problems: Understanding Tactile Feedback

Hard pedal operation requires excessive force for normal clutch disengagement, often indicating problems with the release mechanism or hydraulic system. Binding in mechanical linkages, seized release bearings, or high-pressure hydraulic issues can dramatically increase the effort needed for clutch operation.

Soft or spongy pedal feel suggests hydraulic system problems, particularly air in the fluid lines or worn master cylinder seals. The pedal may feel normal initially but gradually sink toward the floor under maintained pressure, indicating internal fluid bypass in the hydraulic components.

Pedal sticking occurs when the clutch fails to return to its normal position after depression, often caused by binding in the linkage, contaminated hydraulic fluid, or damaged return springs. This condition can leave the clutch partially disengaged, causing slipping or overheating.

Vibration through the clutch pedal during operation indicates problems with rotating components, such as warped pressure plates, damaged flywheels, or worn release bearings. These vibrations often correlate with engine RPM and may worsen under load or at specific operating speeds.

Diagnosis methods include systematic pedal travel measurement and force testing. Professional technicians measure pedal travel distance, required force, and consistency of operation to isolate specific component problems. Hydraulic system pressure testing helps identify internal leaks or blockages affecting pedal feel.

Noise Indicators: Decoding Clutch Sounds

Squealing noises typically indicate release bearing wear or inadequate lubrication in mechanical components. These high-pitched sounds often occur when pressing the clutch pedal and may worsen as bearing wear progresses. Early intervention can prevent bearing seizure and more extensive damage.

Grinding sounds suggest metal-to-metal contact within the clutch system, often indicating worn friction material, damaged pressure plate fingers, or failed release bearings. These sounds represent serious component damage requiring immediate attention to prevent further destruction.

Chattering during clutch engagement creates a rapid vibration or stuttering feel, usually caused by contaminated friction surfaces, warped components, or worn engine mounts that allow excessive drivetrain movement. Chattering stresses all drivetrain components and typically worsens over time.

Rattling noises may indicate loose components or worn damper springs within the clutch disc assembly. These sounds often occur at idle with the transmission in neutral and may disappear when the clutch pedal is pressed, helping isolate the source to specific components.

Sound isolation techniques help technicians identify noise sources by operating the clutch under different conditions while listening for changes in sound characteristics. Professional diagnosis may use stethoscopes or electronic listening devices to pinpoint specific component problems.

Visual and Olfactory Signs

Burning smells from the clutch area indicate overheating friction material, typically caused by excessive slipping or riding the clutch during operation. This distinctive, acrid odor suggests immediate attention is needed to prevent permanent damage to the clutch disc and potentially the flywheel surface.

Fine clutch dust around the transmission bellhousing indicates excessive friction material wear, visible as dark, powdery residue. This dust accumulation suggests advanced wear and potential contamination of other components requiring thorough cleaning during repair.

Hydraulic fluid leaks appear as clear or slightly amber fluid around the master cylinder, slave cylinder, or connecting lines. These leaks compromise system operation and may lead to complete clutch failure if fluid levels drop too low for proper pressure generation.

Visible damage to external components includes cracked bellhousings, damaged release forks, or corroded hydraulic lines. External inspection can reveal obvious problems and guide more detailed internal diagnosis when external symptoms suggest internal component damage.

For detailed guidance on specific clutch component failures, refer to our comprehensive articles on clutch pressure plate problems and clutch master cylinder issues.

Diagnostic Procedures: Professional Testing Methods

Basic Diagnostic Tests

Visual Inspection Protocol

External component assessment begins with systematic examination of all visible clutch system parts, including the hydraulic reservoir, master cylinder, slave cylinder, and connecting lines. Look for fluid leaks, corrosion, physical damage, or obvious wear patterns that indicate specific component problems.

Hydraulic system checks focus on fluid level and quality in the reservoir, ensuring adequate fluid for proper operation and checking for contamination that could affect system performance. Dark, cloudy, or debris-contaminated fluid indicates the need for system flushing and possible component replacement.

Linkage inspection in mechanical systems involves examining cables, adjustment points, and pivot mechanisms for wear, binding, or improper adjustment. These components must operate smoothly throughout their full range of motion without excessive play or resistance.

Safety preparations include proper vehicle positioning on level ground with parking brake engaged and wheel chocks in place. Ensure adequate lighting and tool access while maintaining awareness of safety hazards like hot exhaust components or moving engine parts during diagnosis.

Operational Testing Procedures

Engagement point testing determines the clutch’s operating characteristics by slowly releasing the pedal from full depression while monitoring the point where power transfer begins. Changes in engagement point height or inconsistent engagement indicate developing problems requiring further investigation.

Slip testing involves controlled load application while monitoring engine RPM versus vehicle response. Professional techniques include parking brake application while attempting acceleration, or hill start procedures that reveal slip under known load conditions. These tests must be performed carefully to avoid unnecessary component damage.

Noise isolation requires systematic operation under different conditions while listening for specific sound patterns. Testing includes engine running with transmission in neutral, clutch pedal operation at various RPMs, and engagement under different load conditions to identify noise sources.

Pedal feel evaluation assesses force requirements and travel distance throughout the full operating range. Consistent pedal effort and smooth travel indicate proper system operation, while changes in resistance, excessive travel, or inconsistent feel suggest specific component problems.

Advanced Diagnostic Techniques

Hydraulic System Testing

Pressure testing measures actual system pressure during operation, comparing results to manufacturer specifications to identify performance problems. Professional pressure gauges connect to test points in the hydraulic system, allowing precise measurement under various operating conditions.

Fluid analysis examines contamination and degradation that affects system performance, including moisture content, metal particles, and chemical breakdown that indicate internal component wear. Laboratory analysis can reveal specific contamination sources and guide repair strategies.

Bleeding procedures remove air from the hydraulic system that compresses under pressure and reduces system effectiveness. Professional bleeding equipment ensures complete air removal while preventing contamination introduction during the process.

Component function testing verifies master and slave cylinder operation through pressure testing, travel measurement, and leak detection. This testing isolates specific component problems and determines whether repair or replacement is necessary for reliable operation.

Component-Specific Diagnosis

Flywheel assessment requires transmission removal for direct inspection of surface condition, dimensional accuracy, and heat damage. Professional measurement includes runout testing, thickness verification, and surface finish analysis to determine machining or replacement requirements.

Pressure plate testing evaluates spring tension and finger alignment through specialized equipment that measures clamping force and release characteristics. These tests determine whether pressure plate performance meets manufacturer specifications for proper clutch operation.

Release bearing inspection checks rotation smoothness and noise generation while verifying proper contact with pressure plate fingers. Bearing replacement typically occurs during clutch service, but advanced wear may indicate other system problems requiring investigation.

Input shaft examination includes spline condition assessment and pilot bearing evaluation for wear patterns that indicate alignment problems or inadequate lubrication. These components critically affect clutch operation and transmission reliability.

Professional Equipment Requirements

Transmission jacks provide safe support during transmission removal and installation, preventing component damage and technician injury during heavy component handling. Professional jacks include positioning adjustments for precise alignment during installation.

Dial indicators enable precise measurement of component runout, alignment, and dimensional accuracy that affects clutch operation. These tools ensure proper component relationships and identify problems not visible through casual inspection.

Pressure gauges for hydraulic system testing must match system operating pressures and provide accurate readings throughout the pressure range. Professional equipment includes fittings for various vehicle applications and safety features for high-pressure testing.

Specialized clutch tools include alignment tools for proper installation, spring compressors for pressure plate service, and pilot bearing pullers for component removal. These tools ensure proper installation and prevent component damage during service procedures.

For vehicle-specific diagnostic procedures and specifications, consult the appropriate service manuals available through our brand-specific manual collections.

Clutch Repair and Replacement: Procedures and Considerations

Professional Repair Process

Component Replacement Procedure

Transmission removal requires systematic disconnection of all electrical connections, drive shafts, shift linkages, and support components before safely lowering the transmission. Professional procedures ensure proper component protection and maintain safety throughout the disassembly process.

Component assessment during disassembly determines which parts require replacement versus cleaning and inspection. Experienced technicians evaluate wear patterns, damage extent, and remaining service life to recommend comprehensive repair strategies that prevent premature failure.

Installation sequence follows specific procedures to ensure proper component alignment and torque specifications. Critical steps include clutch disc alignment, pressure plate bolt tightening sequence, and flywheel bolt torque verification to prevent distortion or misalignment that affects operation.

Alignment procedures ensure proper component positioning using specialized alignment tools that center the clutch disc with the transmission input shaft. Improper alignment causes difficult installation and premature wear, making this step critical for successful repair.

System testing after installation verifies proper operation through controlled engagement testing, pedal feel assessment, and operational verification under various load conditions. Professional testing ensures the repair meets performance standards before vehicle delivery.

Related Service Requirements

Flywheel machining restores proper surface condition for optimal clutch disc contact, removing heat damage, scoring, and wear that affects friction characteristics. Professional machining maintains dimensional specifications while creating the surface finish necessary for proper operation.

Hydraulic system service includes complete fluid replacement and system bleeding to remove contamination and air that affects operation. Fresh brake fluid prevents seal damage and ensures consistent hydraulic pressure throughout the system’s service life.

Pilot bearing replacement during clutch service prevents future problems since accessing this component requires transmission removal. New pilot bearings ensure proper input shaft support and prevent noise or vibration problems that could develop before the next clutch service.

Transmission fluid replacement may be recommended when transmission removal provides access for complete fluid change. Fresh fluid removes contamination and wear particles while providing optimal lubrication for extended transmission life.

DIY Considerations and Limitations

DIY Assessment Criteria

Skill level requirements include mechanical experience with heavy component handling, precision measurement, and complex assembly procedures. Clutch replacement demands understanding of torque specifications, alignment procedures, and safety requirements that exceed basic maintenance skills.

Equipment needs extend beyond typical home workshops to include transmission jacks, engine supports, specialized alignment tools, and precision measuring equipment. Professional shops invest thousands of dollars in equipment necessary for safe, proper clutch replacement.

Safety considerations involve heavy component weights exceeding 100 pounds for some transmissions, hydraulic fluid exposure risks, and potential for serious injury during component handling. Professional technicians use specialized equipment and procedures to minimize these risks.

Time investment typically ranges from 8-16 hours for experienced DIY mechanics, depending on vehicle complexity and unforeseen complications. Professional shops complete the same work in 4-8 hours using specialized equipment and established procedures.

When Professional Help is Essential

Safety-critical procedures include heavy component handling and hydraulic system pressure testing that pose significant injury risks without proper equipment and experience. Professional shops maintain insurance and safety protocols that protect both technicians and customers.

Specialized equipment requirements exceed most home workshop capabilities, including transmission jacks, alignment tools, pressure testing equipment, and precision measuring devices necessary for proper installation and verification.

Warranty considerations often require professional installation for parts coverage, especially for expensive components like dual mass flywheels or performance clutch systems. DIY installation may void manufacturer warranties and increase long-term costs.

Complex diagnosis beyond basic symptoms requires professional experience and equipment to identify root causes and prevent repeat failures. Experienced technicians recognize patterns and relationships that prevent costly misdiagnosis and unnecessary repairs.

For detailed clutch component diagnosis and replacement procedures, refer to our comprehensive clutch problem guide and vehicle-specific service information.

Cost Analysis: Understanding Clutch Repair Expenses

Factors Affecting Repair Costs

Vehicle-Specific Variables

Make and model significantly impact repair costs due to differences in component accessibility, parts pricing, and labor complexity. Luxury vehicles typically cost 50-100% more than economy cars due to expensive parts and specialized labor requirements, while some exotic vehicles may require dealer-only service.

Engine configuration affects labor time and complexity, with transverse-mounted engines often requiring more disassembly than longitudinal layouts. Front-wheel-drive vehicles may need engine support during transmission removal, while rear-wheel-drive vehicles typically provide better access but may require exhaust system removal.

Transmission type influences cost through complexity differences between 2WD and 4WD systems. Four-wheel-drive vehicles often require transfer case removal or special procedures that increase labor time, while some all-wheel-drive systems need complete drivetrain disassembly for clutch access.

Component availability affects both parts cost and repair timing, with common vehicles typically having competitive aftermarket options while rare or discontinued models may require expensive OEM parts. Import vehicle parts often cost more due to shipping and limited availability.

Repair Scope Variations

Basic clutch kit replacement includes the clutch disc, pressure plate, and release bearing – the minimum components needed for proper operation. This approach works when other components like the flywheel and hydraulic system remain in good condition.

Complete system overhaul includes flywheel machining or replacement, hydraulic component service, and related repairs that ensure long-term reliability. While initially more expensive, comprehensive repair often provides better value by preventing near-term repeat failures.

Related repairs frequently become necessary during clutch replacement when inspection reveals worn or damaged components. Common additions include rear main seal replacement, pilot bearing service, and engine mount replacement that requires similar disassembly procedures.

Emergency versus planned repair affects costs through rush service premiums, limited shop availability, and reduced time for competitive estimates. Planning clutch replacement during early symptom stages allows better cost control and scheduling flexibility.

Cost Breakdown Analysis

Parts Costs by Vehicle Category

Economy vehicles typically require $120-$300 for basic clutch kits from reputable aftermarket manufacturers, with OEM parts adding $50-$150 to these costs. Simple designs and high production volumes keep parts costs reasonable for most mainstream vehicles.

Mid-range vehicles cost $200-$600 for standard replacement parts, reflecting more complex designs and higher-quality components. These vehicles often benefit from OEM parts quality, especially for hydraulic components that affect long-term reliability.

Performance and luxury vehicles require $400-$1,200 for premium components designed to handle higher power levels and provide enhanced durability. Specialized materials and limited production volumes contribute to significantly higher parts costs.

OEM versus aftermarket parts present quality and cost trade-offs requiring careful consideration. OEM parts ensure exact fit and performance but cost 25-50% more than quality aftermarket alternatives. Cheap aftermarket parts may save money initially but often provide shorter service life.

Labor Costs and Regional Variations

Typical labor requirements range from 4-8 hours depending on vehicle complexity and shop efficiency. Simple rear-wheel-drive vehicles may require only 4-5 hours, while complex front-wheel-drive or all-wheel-drive systems can take 8-10 hours for complete service.

Regional labor rates vary from $75-$125 per hour based on local economic conditions and shop specialization. Urban areas typically charge higher rates due to increased overhead costs, while rural areas may offer lower rates but limited specialized expertise.

Dealer versus independent shop costs reflect different overhead structures and specialization levels. Dealers typically charge 20-40% more but provide warranty coverage and specialized training, while independent shops offer competitive pricing with varying expertise levels.

Total project costs typically range from $800-$3,000 for complete clutch replacement, including parts and labor. Economy vehicles fall at the lower end of this range, while luxury or performance vehicles approach or exceed the upper limits.

Cost-Saving Strategies

Preventive maintenance extends clutch life through proper driving techniques, regular hydraulic system service, and early problem recognition. Good driving habits can double clutch life, representing thousands of dollars in delayed replacement costs.

Shop comparison requires obtaining detailed estimates from multiple qualified shops, ensuring comparable scope and parts quality for accurate comparison. Written estimates help prevent unexpected charges and provide legal protection for both parties.

Parts selection involves balancing quality and cost considerations through research of manufacturer reputations, warranty coverage, and performance requirements. Premium parts may justify higher costs for performance vehicles or commercial applications.

Timing optimization can reduce costs by scheduling repairs during slower periods when shops may offer discounts, or combining clutch replacement with other major service items that require similar disassembly procedures.

For vehicle-specific parts and repair information, consult our extensive vehicle manual database for detailed specifications and procedures.

Preventive Maintenance: Extending Clutch Life

Driving Habits for Longevity

Proper Operating Techniques

Smooth engagement through gradual pedal release minimizes shock loads on drivetrain components while reducing friction material wear. Proper technique involves finding the engagement point, then smoothly releasing the pedal to allow gradual power transfer without slipping or jolting.

Avoiding riding the clutch means keeping your foot completely off the pedal except during gear changes. Resting your foot on the pedal maintains slight pressure on the release bearing, causing premature wear and reducing clutch life significantly. Use the dead pedal or floor area for left foot rest.

Hill starts using the handbrake prevent clutch overheating and excessive wear from holding the vehicle stationary with clutch slip. Proper technique involves setting the handbrake, finding the clutch engagement point, then releasing the brake as you complete clutch engagement for smooth starts without rollback.

Traffic management includes minimizing stop-and-go clutch usage by maintaining following distances that allow coasting to traffic lights and reducing unnecessary gear changes. Anticipating traffic flow reduces clutch cycles and heat generation, extending component life significantly.

Load and Stress Management

Towing capacity adherence prevents clutch overloading beyond design specifications, avoiding excessive heat generation and premature wear. Exceeding towing limits forces the clutch to slip under loads it wasn’t designed to handle, causing rapid friction material degradation and potential flywheel damage.

Aggressive driving avoidance includes eliminating high-RPM engagement and racing starts that generate excessive heat and shock loads. Performance driving techniques may be entertaining but dramatically reduce clutch life and increase the risk of sudden component failure.

Environmental factors like dust, moisture, and extreme temperatures affect clutch operation and longevity. Dusty conditions accelerate friction material wear, while moisture can cause corrosion and hydraulic system problems. Extreme heat reduces component life, while extreme cold affects hydraulic fluid viscosity and system response.

Performance modifications impact clutch durability and may require upgraded components to handle increased power levels. Engine modifications that increase torque output can overwhelm stock clutch capacity, necessitating performance clutch selection and installation for reliable operation.

Maintenance Schedule and Inspections

Regular Service Intervals

Hydraulic fluid replacement every 2-3 years prevents contamination buildup and maintains proper system operation. Brake fluid absorbs moisture over time, reducing performance and potentially damaging internal seals in master and slave cylinders.

Annual system inspections should include pedal feel assessment, engagement point verification, and visual inspection of external components. Early problem detection prevents minor issues from developing into major failures requiring expensive repairs.

Early warning recognition involves understanding normal clutch behavior and noting changes in pedal feel, engagement characteristics, or operating sounds. Immediate attention to developing problems can often prevent complete failure and reduce repair costs.

Professional evaluation timing depends on vehicle age, mileage, and operating conditions. High-mileage vehicles or those used in severe service may benefit from annual professional assessment, while newer vehicles under normal use may only need evaluation when symptoms develop.

Component Monitoring

Pedal feel changes often indicate developing problems before obvious symptoms appear. Increasing pedal effort, changes in engagement point, or inconsistent feel suggest hydraulic problems or component wear requiring investigation.

Engagement point monitoring involves noting the pedal position where power transfer begins. Gradual changes in engagement height may indicate automatic adjustment system operation, while sudden changes suggest component problems requiring attention.

Noise development should be investigated promptly since clutch noises typically worsen rapidly and may indicate impending component failure. Early intervention when noises first appear can often prevent more extensive damage and expensive repairs.

Performance degradation includes subtle changes in acceleration response, gear shifting smoothness, or overall drivability that may indicate developing clutch problems. Professional diagnosis can identify problems before complete failure occurs.

Safety Considerations and Professional Guidance

Safety Protocols

Operational Safety

Immediate response to clutch failure involves safely stopping the vehicle and avoiding continued operation that could cause additional damage or create safety hazards. Complete clutch failure may prevent gear changes or cause unexpected vehicle behavior requiring immediate attention.

Emergency procedures for limited clutch function include engine-off shifting techniques for reaching safe locations, but these methods should only be used in genuine emergencies. Repeated use of emergency procedures can damage the starter motor and transmission components.

Warning signs requiring immediate attention include complete loss of clutch engagement, sudden changes in pedal feel, burning smells, or any condition that affects safe vehicle operation. Ignoring critical symptoms risks sudden failure and potential safety hazards.

Professional intervention becomes essential when clutch problems affect safety, create unpredictable vehicle behavior, or exceed the driver’s ability to compensate. Attempting to drive with serious clutch problems risks accident involvement and expensive additional damage.

Repair Safety

DIY limitations must be honestly assessed based on mechanical experience, available equipment, and safety considerations. Clutch replacement involves heavy components, hazardous materials, and procedures that can cause serious injury without proper training and equipment.

Professional requirements for complex procedures include specialized lifting equipment, pressure testing tools, and experience with safety protocols that protect both technicians and vehicles. Professional shops maintain insurance coverage and safety training that protects all parties.

Health hazards from clutch dust exposure require proper respiratory protection and disposal procedures, as friction material may contain harmful substances. Professional shops use appropriate safety equipment and follow environmental regulations for safe disposal.

Tool safety involves proper use of transmission jacks, engine hoists, and hydraulic equipment that can cause serious injury if misused. Professional training and equipment maintenance ensure safe operation throughout repair procedures.

When to Seek Professional Help

Diagnostic uncertainty beyond basic symptoms requires professional experience and equipment to identify root causes and prevent misdiagnosis. Complex problems may involve multiple systems or subtle component interactions that require specialized knowledge.

Safety-critical issues affecting vehicle operation should always receive professional attention to ensure proper repair and prevent potential accidents. Clutch problems that affect steering, braking, or predictable vehicle response require immediate professional intervention.

Warranty considerations may require professional service to maintain coverage for expensive components or complete vehicle warranties. Professional documentation and proper procedures protect warranty coverage and prevent costly disputes.

Quality assurance through professional service provides warranty coverage, proper procedures, and accountability that protect your investment. Professional shops stake their reputation on quality work and stand behind their repairs with warranties and guarantees.

For comprehensive vehicle-specific repair procedures and safety information, consult our professional manual library covering all major manufacturers and vehicle types.

Conclusion: Mastering Clutch Maintenance and Repair

Key Takeaways

Understanding clutch symptoms enables early problem recognition that can prevent major failures and reduce repair costs significantly. The difference between minor adjustment and complete replacement often depends on how quickly problems are identified and addressed.

Component knowledge empowers informed repair decisions by helping you understand what failed, why it failed, and what’s needed for reliable repair. This knowledge prevents unnecessary repairs while ensuring comprehensive solutions that provide long-term reliability.

Cost management through realistic expectations and proper planning allows budget preparation and prevents surprise expenses. Understanding typical costs, factors affecting pricing, and cost-saving strategies helps manage this significant vehicle expense.

Safety priority requires professional help for complex diagnosis, safety-critical repairs, and situations beyond individual capabilities. Recognizing these limitations protects both personal safety and prevents costly mistakes that could multiply repair expenses.

Action Steps for Vehicle Owners

Regular monitoring of clutch performance includes paying attention to pedal feel, engagement characteristics, and any changes in normal operation. Early recognition of developing problems provides the best opportunity for cost-effective solutions.

Preventive maintenance through proper driving habits and scheduled service can double or triple clutch life, representing thousands of dollars in delayed replacement costs. Good habits cost nothing but provide enormous long-term value.

Professional relationships with trusted mechanics ensure access to quality service, fair pricing, and honest advice when problems develop. Building these relationships before problems occur provides better service and peace of mind.

Educational investment in understanding your vehicle pays dividends through better maintenance decisions, early problem recognition, and informed discussions with service providers. Knowledge is your best protection against unnecessary repairs and expenses.

Resources for Further Learning

Technical manuals provide vehicle-specific information for detailed procedures, specifications, and troubleshooting that goes beyond general guidance. Our comprehensive manual collection covers virtually every vehicle make and model.

Professional training opportunities exist for those interested in developing automotive repair skills, from community college courses to manufacturer training programs. Proper training provides both knowledge and safety awareness essential for successful repairs.

Community support through online forums and local automotive groups connects you with experienced enthusiasts and professionals willing to share knowledge and advice. These communities provide valuable real-world experience and troubleshooting assistance.

Repairs Advisor serves as your comprehensive resource for technical manuals, repair procedures, and professional guidance covering all aspects of vehicle maintenance and repair. Our extensive library provides the detailed information needed for informed decisions and successful repairs.

Important Safety Disclaimer: This information is provided for educational purposes only. Clutch repair involves heavy components, hazardous materials, and procedures that can cause serious injury or death without proper training and equipment. Always consult qualified professionals for diagnosis and repair of clutch systems. Implement any procedures at your own risk and responsibility. When in doubt, seek professional assistance to ensure safe and reliable repairs.

For vehicle-specific clutch repair procedures, diagnostic information, and detailed component specifications, explore our comprehensive manual collection covering Ford, Toyota, Honda, Chevrolet, and hundreds of other manufacturers and models.