Your engine’s cooling system works tirelessly to maintain optimal operating temperatures, but there’s one component that often goes unnoticed until it fails: the cooling fan clutch. This thermostatic device serves as your engine’s intelligent helper, automatically adjusting fan speed based on temperature needs while saving fuel and reducing noise. Most drivers never think about their fan clutch until they’re stuck in traffic with an overheating engine or dealing with excessive fan noise on the highway.

When a cooling fan clutch fails, the consequences can range from annoying to catastrophic. Engine overheating at idle, constant roaring fan noise, poor fuel economy, and reduced performance are just the beginning. Left unaddressed, a faulty fan clutch can lead to severe engine damage, including warped cylinder heads, blown gaskets, and complete engine failure—repairs that can cost thousands of dollars.

This comprehensive guide provides everything you need to understand, diagnose, and repair cooling fan clutch problems safely and effectively. Whether you’re a DIY enthusiast looking to save money, a professional mechanic seeking detailed procedures, or a vehicle owner trying to understand symptoms, you’ll find professional-level guidance with a safety-first approach. We’ll cover the different types of fan clutches, comprehensive symptom recognition, professional diagnostic techniques, step-by-step repair procedures, cost analysis, and preventive maintenance strategies.

Understanding your cooling fan clutch isn’t just about fixing problems—it’s about preventing expensive engine damage and ensuring reliable vehicle operation. The knowledge you gain here will help you make informed decisions about repairs and maintenance while keeping safety as the top priority. For comprehensive cooling system maintenance, also review our guide on understanding coolant and when it needs replacing to ensure your entire cooling system works in harmony.

What is a Cooling Fan Clutch and How Does It Work?

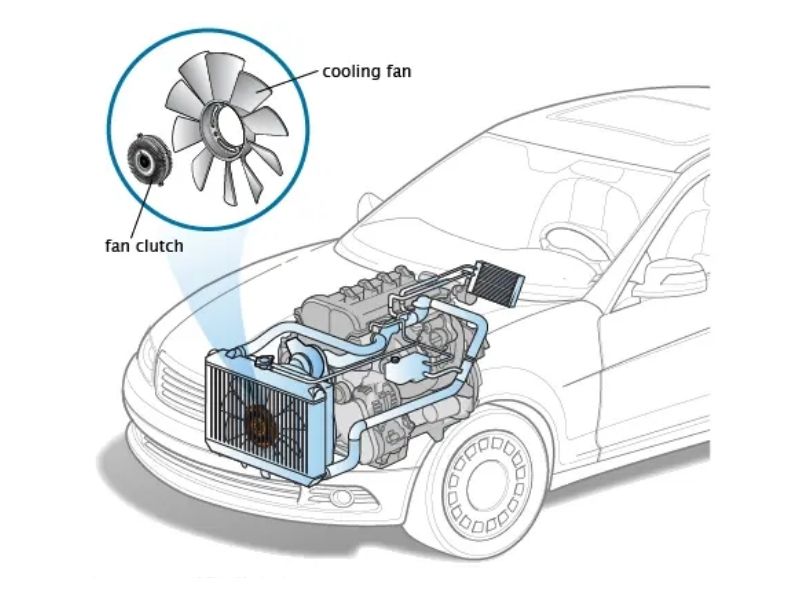

A cooling fan clutch is a thermostatic device that controls the engagement of your engine’s cooling fan based on temperature needs. Unlike electric cooling fans found in most modern vehicles, mechanical fan clutches operate through a viscous coupling system that automatically adjusts fan speed in response to engine temperature. This intelligent design saves engine power when cooling isn’t needed while providing maximum airflow when temperatures rise.

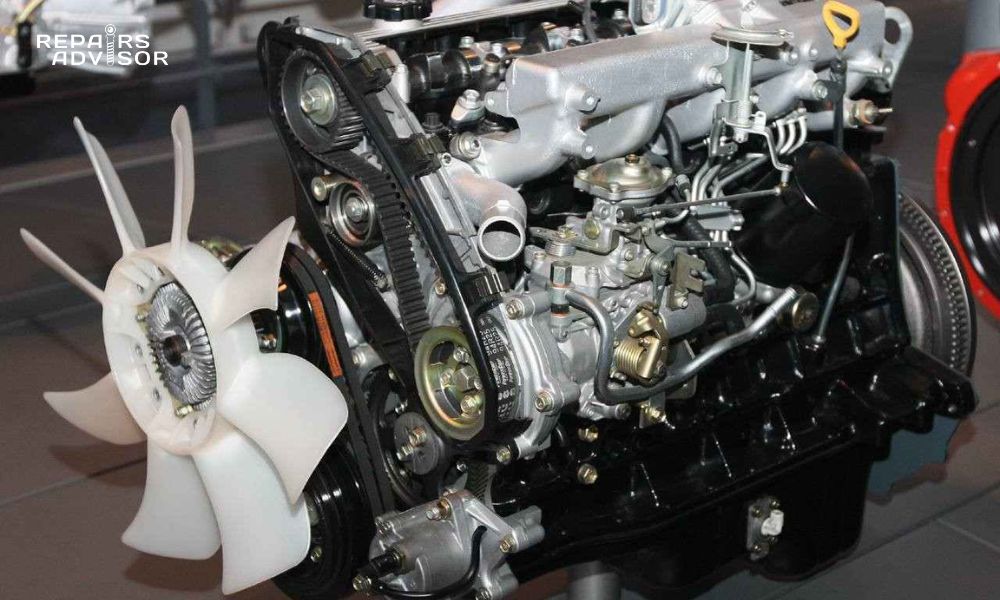

The fan clutch mounts directly to the water pump shaft or engine-driven pulley, positioning it at the front of the engine where it can respond to radiator heat. During normal operating conditions, the clutch allows the fan to spin at reduced speed, consuming minimal engine power and generating less noise. When engine temperature increases or the vehicle operates at low speeds with insufficient airflow, the clutch engages more fully, spinning the fan faster to pull additional air through the radiator.

The operating principle relies on a silicone-based viscous fluid contained within the clutch assembly. This fluid transfers torque between the drive hub and fan assembly, with engagement levels controlled by internal valves. Temperature changes affect the position of these valves, which in turn regulates fluid flow and determines how much torque transfers to the fan. This system provides smooth, progressive engagement rather than the on-off operation of electric fans.

Modern cooling systems integrate multiple components, and understanding how they work together is crucial for effective diagnosis and repair. The fan clutch works in conjunction with the radiator, water pump, thermostat, and coolant to maintain optimal engine temperature. For vehicles with both mechanical and electric cooling systems, you might also want to understand cooling fan motor operation to get the complete picture.

Types of Cooling Fan Clutches

Non-Thermal (Centrifugal) Clutches

Non-thermal fan clutches operate based on centrifugal force rather than temperature. These simpler designs engage at a constant percentage of engine RPM, typically 30-60%, regardless of engine temperature. While less expensive than thermal clutches, they offer limited efficiency benefits because they remain partially engaged at all times.

The primary advantage of non-thermal clutches is their simplicity and lower initial cost. They have fewer moving parts and don’t rely on temperature-sensitive components that can fail over time. However, this simplicity comes at the cost of fuel economy and noise reduction, as the fan operates at higher speeds even when cooling isn’t needed.

Non-thermal clutches are most commonly found in older vehicles or budget applications where cost takes priority over efficiency. They’re less common in modern vehicles due to their inferior performance characteristics compared to thermal alternatives.

Thermal (Temperature-Controlled) Clutches

Thermal fan clutches represent the most common and efficient design for mechanical cooling fans. These units feature a bi-metallic thermal spring on the front face that responds to air temperature changes. As hot air flows through the radiator, it heats the thermal spring, causing it to expand and actuate an internal valve that increases clutch engagement.

The thermal spring typically begins opening the valve at around 180°F and reaches full engagement by 200°F, though these specifications vary by application. This temperature-responsive operation ensures the fan operates at minimum speed during cold weather and city driving while providing maximum cooling during heavy loads or high ambient temperatures.

Thermal clutches come in three main variants: standard duty, heavy duty, and severe duty. Standard duty clutches provide basic temperature control suitable for normal passenger car applications. Heavy duty units offer increased torque capacity and faster engagement for trucks and performance vehicles. Severe duty clutches feature the most aggressive engagement characteristics and largest working surface area, designed for commercial vehicles and extreme operating conditions.

Electronic Fan Clutches

Electronic fan clutches represent the most advanced mechanical cooling technology, combining viscous coupling with electronic control. Instead of relying solely on a bi-metallic spring, these units receive control signals from the engine control module (ECM) or powertrain control module (PCM) based on inputs from multiple sensors throughout the vehicle.

Electronic clutches can consider coolant temperature, intake air temperature, transmission fluid temperature, air conditioning system pressure, and ambient air temperature when determining optimal fan speed. This comprehensive approach provides superior temperature control and can optimize fan operation for specific driving conditions.

The electronic control allows for variable engagement levels rather than simple on-off operation. The PCM can command partial engagement for moderate cooling needs or full engagement for maximum cooling capacity. This precision control offers the best possible balance of cooling effectiveness, fuel economy, and noise reduction.

Understanding transmission temperature is particularly important for electronic fan clutches, especially in vehicles that tow or operate under heavy loads. For comprehensive information about transmission fluid maintenance that affects cooling system operation, review our guide on understanding and maintaining automatic transmission fluid.

Signs Your Cooling Fan Clutch is Failing

Recognizing fan clutch failure symptoms early can prevent costly engine damage and avoid unexpected breakdowns. Fan clutch problems typically develop gradually, with symptoms becoming more pronounced as the condition worsens. Understanding these warning signs helps you address issues before they lead to serious engine problems.

Engine Overheating at Low Speeds

The most common and serious symptom of fan clutch failure is engine overheating during idle or low-speed operation. When the clutch fails to engage properly, insufficient airflow passes through the radiator, causing coolant temperatures to rise beyond safe operating limits. This condition is particularly noticeable during stop-and-go traffic, extended idling, or driving at low speeds on hot days.

What makes this symptom particularly telling is that the engine typically maintains normal temperatures at highway speeds. When driving at 45+ mph, natural airflow through the radiator provides adequate cooling even with a failed fan clutch. However, once vehicle speed drops and natural airflow decreases, the faulty clutch cannot compensate, resulting in rising temperatures.

It’s crucial to distinguish fan clutch-related overheating from other cooling system problems. If adding coolant doesn’t resolve the overheating or if the problem only occurs at low speeds, the fan clutch is likely the culprit. Other cooling system issues typically cause overheating under various conditions, not just at idle or low speeds.

Safety Warning: Never ignore engine overheating symptoms. Continued operation with an overheating engine can cause severe damage including cracked cylinder heads, blown head gaskets, and complete engine failure. If your engine overheats, pull over safely, turn off the engine, and allow it to cool completely before inspection.

Excessive Fan Noise

A fan clutch stuck in the engaged position produces excessive noise that’s immediately noticeable to anyone familiar with normal engine operation. Instead of the clutch disengaging at highway speeds when cooling isn’t needed, a seized clutch keeps the fan spinning at high speed, creating a constant roaring sound similar to a jet engine.

This condition typically results from internal clutch failure where the silicone fluid has degraded or internal components have seized. While a stuck-engaged clutch won’t cause overheating, it creates several other problems including reduced fuel economy, decreased engine performance, and excessive noise that makes highway driving unpleasant.

The noise is most noticeable during cold engine operation when the fan should be spinning slowly or during highway driving when the fan should disengage almost completely. If you hear constant fan roar regardless of engine temperature or driving speed, the clutch has likely seized in the engaged position.

Pay attention to when the noise occurs. Normal fan clutch engagement produces increased noise only when the engine reaches operating temperature and cooling is needed. Abnormal noise occurs constantly or at inappropriate times, indicating clutch malfunction.

Poor Engine Performance

A failing fan clutch can significantly impact engine performance by creating excessive parasitic drag on the engine. When the clutch fails to disengage properly, it forces the engine to continuously drive the fan at high speed, consuming power that should be available for acceleration and normal operation.

The performance impact is most noticeable during acceleration, where the engine struggles to reach higher RPMs efficiently. You might notice sluggish acceleration, reduced power at highway speeds, or the engine working harder than normal to maintain speed. Fuel economy typically decreases as the engine compensates for the additional load.

In cold weather, a stuck-engaged clutch can prevent the engine from reaching proper operating temperature, leading to poor fuel atomization, increased emissions, and reduced efficiency. The engine may take longer to warm up and might never reach optimal operating temperature during short trips.

Performance problems can be subtle and might develop gradually as the clutch condition worsens. Many drivers attribute these symptoms to normal aging or other mechanical issues, not realizing the fan clutch is the culprit.

Physical Inspection Indicators

Visual inspection can reveal several fan clutch problems before they cause major symptoms. Oil leaks around the clutch hub are one of the most obvious signs of internal failure. The silicone fluid used in viscous clutches can leak from worn seals, creating streaks that radiate outward from the center hub due to centrifugal force.

Fan wobble indicates worn bearings or mounting problems within the clutch assembly. With the engine off, you should be able to move the fan slightly by hand, but excessive movement or wobbling motion suggests internal wear that will only worsen with continued operation.

The thermal spring on thermal clutches should be present and properly positioned. Missing, damaged, or obviously deteriorated springs indicate the clutch cannot respond properly to temperature changes. Some aftermarket clutches lack thermal springs entirely, making them essentially non-thermal units with limited efficiency.

Check for physical damage to the fan blades, mounting bolts, or clutch housing. Cracked or bent fan blades can cause vibration and reduce cooling effectiveness. Loose mounting bolts allow excessive movement that can damage the water pump or other components.

Diagnostic Trouble Codes

Modern vehicles with electronic engine management systems may store diagnostic trouble codes related to fan clutch operation. While mechanical fan clutches don’t directly interface with the PCM, related sensors and systems can trigger codes when cooling system problems occur.

Common codes include those related to engine overheating, coolant temperature sensor faults, or cooling system performance. Code P0128, which indicates coolant temperature below thermostat regulating temperature, can sometimes relate to fan clutch problems that prevent proper engine warm-up. For detailed information about this specific code, see our guide on Code P0128: Coolant Temperature Below Thermostat Regulating Temperature.

Electronic fan clutches may trigger specific codes related to clutch control circuit problems, sensor faults, or performance issues. These codes require scan tool diagnosis and proper interpretation to determine if the clutch itself has failed or if related sensors or circuits are causing the problem.

Don’t ignore check engine lights, especially if accompanied by other cooling system symptoms. The PCM monitors various parameters that can indicate cooling system problems before they become severe enough to cause overheating.

How to Diagnose a Failing Fan Clutch

Proper diagnosis of fan clutch problems requires systematic testing using both simple visual inspections and more advanced techniques. Professional diagnosis prevents unnecessary parts replacement and ensures you address the actual problem rather than symptoms caused by other issues.

Safety First: Always ensure the engine is completely cool before beginning any fan clutch inspection. Hot engines and cooling system components can cause severe burns. Never work on a hot engine or attempt to test a fan clutch immediately after engine operation.

Visual Inspection Methods

Physical Condition Assessment

Begin diagnosis with a thorough visual inspection of the fan clutch and surrounding components. Look for obvious signs of fluid leakage around the clutch hub, which appears as dark streaks radiating outward from the center. These streaks typically contain silicone fluid mixed with dirt and debris, creating a distinctive pattern that’s easy to recognize.

Examine the thermal spring (if equipped) for proper positioning and condition. The spring should be securely mounted and show no signs of damage, corrosion, or displacement. A missing or obviously damaged spring indicates the clutch cannot respond properly to temperature changes.

Check the fan blades for cracks, chips, or other damage that could affect balance and performance. Damaged blades can cause vibration that accelerates clutch wear and reduces cooling effectiveness. Also verify that all mounting bolts are present and properly tightened.

Inspect the belt and pulley system for proper alignment and condition. Misaligned pulleys or worn belts can cause excessive clutch wear and affect cooling system performance. A properly aligned system is crucial for optimal fan clutch operation.

Manual Operation Tests

With the engine completely cool and shut off, perform a manual resistance test by spinning the fan by hand. A properly functioning clutch should offer some resistance but allow the fan to turn. The fan should not spin more than 1 to 1.5 complete rotations when spun vigorously by hand. Excessive free-spinning indicates internal clutch wear.

Test for lateral play by attempting to move the fan forward and backward (toward and away from the radiator). Any noticeable movement indicates worn bearings or internal damage. The fan should feel solid with minimal play in any direction.

Check for binding by rotating the fan slowly by hand. The rotation should be smooth and consistent without tight spots or binding. Binding indicates internal damage or contamination that will affect clutch operation.

Listen for unusual noises during manual rotation. Grinding, clicking, or other abnormal sounds suggest bearing wear or internal damage that requires clutch replacement.

Temperature-Based Testing

Thermal Engagement Test

The controlled thermal engagement test provides definitive diagnosis of clutch operation under realistic conditions. This test requires careful monitoring to prevent engine overheating while verifying clutch engagement at proper temperatures.

Cover approximately one-quarter of the radiator’s left and right sides with cardboard or shop rags, leaving the center section completely open. This restriction forces the engine to work harder while maintaining some cooling capacity for safety. Never cover more than half the radiator surface, and always leave the center section open.

Start the engine and monitor the temperature gauge closely. As the engine warms up, listen for changes in fan noise and airflow. A properly functioning thermal clutch should engage dramatically when the air temperature through the radiator reaches approximately 180-200°F, producing a sudden and noticeable increase in fan noise and airflow.

Critical Safety Warning: Never allow the engine temperature to exceed 230°F during this test. If temperatures approach this limit, immediately remove all coverings and allow the engine to cool. Overheating during testing can cause the same engine damage you’re trying to prevent.

The engagement should be obvious when it occurs. You’ll hear a dramatic increase in fan noise, feel significantly more airflow, and notice the temperature gauge stabilize or begin dropping. If the temperature continues rising without obvious fan engagement, the clutch has likely failed.

Thermometer Testing Method

For more precise diagnosis, use a probe-type thermometer capable of reading at least 250°F to measure air temperature at the fan. Insert the thermometer probe through the fan shroud in a location where it can measure airflow temperature without interfering with fan operation.

Monitor air temperature as the engine warms up. The fan clutch should begin engaging when air temperature reaches 150-190°F, with full engagement typically occurring by 200°F. These temperatures may vary slightly depending on the specific clutch design and application.

The thermometer must be probe-type rather than infrared because you need to measure air temperature, not surface temperature. Infrared thermometers will read the temperature of nearby surfaces, which can be significantly different from air temperature.

Allow several minutes for the thermometer reading to stabilize, as conventional thermometers take time to reach equilibrium with the surrounding air temperature. Don’t rely on instant readings, as they may not accurately reflect actual air temperature.

Advanced Diagnostic Techniques

Electronic Fan Clutch Diagnostics

Electronic fan clutches require scan tool diagnosis to properly evaluate PCM commands and sensor inputs. Connect a compatible scan tool and monitor coolant temperature, intake air temperature, and fan clutch command signals while the engine warms up.

Compare actual sensor readings with normal operating parameters for your specific vehicle. Verify that the PCM is receiving accurate temperature information from all relevant sensors and that it’s commanding appropriate fan clutch engagement based on those inputs.

Check for stored diagnostic codes related to cooling system operation or fan clutch control. Even pending codes that haven’t triggered the check engine light can provide valuable diagnostic information.

Monitor fan clutch engagement commands while driving or during controlled testing. The PCM should command increased engagement as temperature rises and decreased engagement when cooling demand decreases.

Performance Measurement

Advanced diagnosis may require measuring actual fan speed using a photo-tachometer or similar instrument. Compare measured fan speeds with manufacturer specifications at various engagement levels to determine if the clutch is performing within acceptable parameters.

Measure fan speed at idle with a cold engine (should be minimal), at operating temperature during idle (moderate engagement), and during controlled thermal testing (maximum engagement). Significant deviation from specifications indicates clutch problems.

For electronic clutches, correlate actual fan speed with PCM commands to determine if the problem lies with the clutch itself or the control system. A clutch that doesn’t respond to PCM commands has internal problems, while a clutch that responds incorrectly may have sensor or wiring issues.

Professional diagnostic equipment can provide detailed analysis, but many fan clutch problems can be accurately diagnosed using the visual and thermal testing methods described above. The key is systematic evaluation that considers all symptoms and test results together.

Fan Clutch Replacement: Professional Repair Procedures

Fan clutch replacement requires careful attention to safety, proper procedures, and quality parts selection. While the basic procedure isn’t extremely complex, the location and connection to critical cooling system components demand respect for safety protocols and manufacturer specifications.

Pre-Repair Preparation

Tools and Equipment Required

Fan clutch replacement requires specific tools that may not be in every mechanic’s toolbox. Most importantly, you’ll need the correct fan clutch removal tool or wrench set for your specific application. These tools are designed to hold the water pump pulley while removing the clutch, preventing damage to the water pump.

Standard tools include a complete socket set, combination wrenches, screwdrivers for shroud removal, and a torque wrench for proper installation. Some applications require reverse-thread awareness, as certain fan clutches use left-hand threads to prevent loosening during operation.

You’ll also need basic safety equipment including safety glasses, work gloves suitable for handling potentially sharp fan blades, and adequate lighting for the work area. If working outdoors, ensure you have proper ventilation and avoid working in windy conditions that could blow debris into the cooling system.

Consider having a drain pan available in case coolant spillage occurs during shroud removal or system manipulation. While fan clutch replacement shouldn’t require coolant draining, preparation prevents mess and environmental contamination.

Safety Protocols

Engine temperature safety is paramount when working on cooling system components. The engine must be completely cool before beginning work, preferably after sitting overnight. Hot engines can cause severe burns, and pressurized cooling systems can spray scalding coolant unexpectedly.

Disconnect the battery negative terminal to prevent accidental electrical contact and ensure cooling fans won’t activate unexpectedly during work. This precaution is especially important on vehicles with both mechanical and electric cooling fans.

Never attempt to work on a fan clutch with the engine running or recently operated. The fan blades can cause serious injury, and moving belts present additional hazards. Always ensure the engine is off and cooled before beginning any work.

Wear appropriate safety equipment and avoid loose clothing that could catch in moving parts. Work gloves protect against sharp edges on fan blades and shroud components, but ensure they don’t interfere with tool operation or dexterity.

Removal Procedures

Fan Assembly Disassembly

Begin by removing the fan shroud to provide adequate working space around the fan clutch. Most shrouds attach with clips or bolts at the top and may sit in brackets at the bottom. Carefully lift the shroud out of the engine compartment, taking care not to damage radiator fins or other components.

With the shroud removed, you’ll have clear access to the fan clutch and mounting hardware. Take note of the fan blade orientation and any spacers or washers between components. These must be reinstalled in the correct order and position.

Some applications require separating the fan blades from the clutch assembly before removing the clutch from the water pump. Others allow removal of the complete assembly as a unit. Consult manufacturer specifications for your specific application to determine the correct procedure.

Clutch Removal from Water Pump

The most critical aspect of fan clutch removal is proper technique to avoid water pump damage. Use the appropriate holding tool to secure the water pump pulley while removing the clutch. Never use impact tools or excessive force, as this can damage internal water pump components.

Many fan clutches use standard right-hand threads, but some applications use left-hand threads that tighten in the opposite direction. Consult service information to determine the correct thread direction for your application. Attempting to remove a left-hand threaded clutch by turning it the wrong direction will only tighten it further.

Apply gentle, steady pressure when loosening the clutch. If it resists removal, verify you’re turning it the correct direction and ensure you’re using the proper tools. Excessive force indicates incorrect procedure or seized threads that may require penetrating oil and additional time.

Once the clutch loosens, remove it completely by hand to avoid dropping it or cross-threading during removal. Handle the old clutch carefully, as it may still contain silicone fluid that could spill and create a mess.

Installation Procedures

New Clutch Installation

Before installing the new clutch, clean the water pump shaft threads and inspect them for damage. Remove any corrosion, old thread sealant, or debris that could interfere with proper installation. The threads should be clean and smooth for proper clutch mounting.

Apply thread sealant or anti-seize compound as specified by the manufacturer. Some applications require specific sealants to prevent loosening, while others use dry installation. Never assume the requirements are the same as other applications you’ve worked on.

Install the new clutch by hand initially to ensure proper thread engagement and prevent cross-threading. The clutch should thread on smoothly without resistance. If you feel binding or resistance, remove the clutch and inspect both the clutch threads and water pump shaft.

System Reassembly and Testing

Tighten the fan clutch to manufacturer specifications using a torque wrench. Proper torque is critical to prevent loosening during operation while avoiding over-tightening that could damage threads or internal components. Torque specifications vary significantly between applications.

Reinstall the fan blades in the correct orientation if they were removed separately. Pay attention to blade pitch and rotation direction, as incorrect installation can reduce cooling effectiveness or cause vibration. Ensure all mounting hardware is properly tightened.

Replace the fan shroud, ensuring proper fit and clearance around the fan assembly. The shroud should not contact the fan blades at any point during rotation. Inadequate clearance can cause noise, vibration, and component damage.

Quality Control and Testing

Post-Installation Verification

Reconnect the battery and perform an initial startup to verify proper installation. Listen for unusual noises, vibration, or other signs of improper installation. The fan should rotate smoothly without contacting the shroud or other components.

Allow the engine to reach operating temperature while monitoring the temperature gauge and listening for proper clutch engagement. The new clutch should engage smoothly and provide adequate cooling without excessive noise or vibration.

Perform a brief test drive to verify normal operation under various conditions. Pay attention to temperature gauge behavior, cooling system performance, and any unusual noises or vibrations that might indicate installation problems.

Check for coolant leaks around the water pump area after the engine has cooled. While fan clutch replacement shouldn’t affect coolant sealing, manipulation of components during service can sometimes disturb seals or connections.

Performance Baseline Establishment

Document the new clutch’s performance characteristics for future reference. Note engagement temperatures, noise levels, and overall cooling system behavior. This baseline information helps identify problems if cooling issues develop in the future.

Consider performing the thermal engagement test described in the diagnostic section to verify the new clutch engages at appropriate temperatures. This test confirms proper operation and provides confidence in the repair.

For comprehensive cooling system maintenance, ensure the coolant is at proper levels and condition. If the coolant hasn’t been changed recently, consider reviewing our guide on understanding coolant and when it needs replacing to optimize overall cooling system performance.

Fan Clutch Replacement Cost and Alternative Solutions

Understanding the financial aspects of fan clutch replacement helps you make informed decisions about repair timing, service provider selection, and alternative solutions. Costs vary significantly based on vehicle type, labor requirements, and part quality, making it important to understand all factors that affect your investment.

Cost Breakdown Analysis

Professional Repair Costs

Professional fan clutch replacement typically requires 1-3 hours of labor, depending on vehicle accessibility and complexity. Labor costs vary by region and shop type, with dealership rates typically higher than independent shops. Average labor costs range from $100-300, with luxury or difficult-to-access applications at the higher end.

Parts costs vary dramatically based on vehicle application and part quality. Basic replacement clutches for common applications may cost $50-150, while heavy-duty or electronic clutches for trucks and performance vehicles can exceed $300. OEM parts typically cost more than aftermarket alternatives but often provide superior longevity and performance.

Total professional repair costs typically range from $200-600 for most applications, with luxury vehicles, trucks, and specialty applications potentially costing more. Geographic location significantly affects costs, with urban areas and regions with higher labor costs seeing prices at the upper end of these ranges.

Additional costs may include cooling system service if contamination or other issues are discovered during repair. Some shops recommend radiator flushing or coolant replacement when performing cooling system repairs, adding $100-200 to the total cost.

DIY Cost Considerations

DIY replacement can reduce costs significantly by eliminating labor charges, but requires proper tools and skills for safe completion. Parts costs remain the same, but you’ll need to invest in any tools you don’t currently own, particularly the fan clutch removal tools specific to your application.

Tool costs can range from $20-100 depending on what you need to purchase. Basic clutch removal tools are relatively inexpensive, but some applications require specialized equipment that may not be cost-effective for a single repair.

Consider the time investment required for DIY repair. While the procedure isn’t extremely complex, it can take 3-5 hours for inexperienced mechanics, particularly if complications arise or additional cooling system service becomes necessary.

Factor in the risk of mistakes that could require professional correction. Improper installation can cause water pump damage, cooling system leaks, or inadequate cooling that leads to engine damage. The potential cost of correcting mistakes may exceed professional repair costs.

Alternative Solutions

Electric Fan Conversion

Converting from a mechanical fan clutch to an electric fan system offers several advantages including improved fuel economy, reduced noise, and more precise temperature control. Electric fan kits for popular applications typically cost $200-500 and can often be installed by experienced DIY mechanics.

Electric conversion requires mounting the new fan, installing temperature sensors and control modules, and running electrical connections. The complexity varies significantly between applications, with some requiring extensive wiring modifications while others use relatively simple bolt-on kits.

Consider the long-term benefits of electric conversion including reduced maintenance, improved fuel economy, and better cooling control. Electric fans don’t consume engine power and can operate after engine shutdown for additional cooling when needed.

However, electric conversion may not be suitable for all applications, particularly heavy-duty trucks or vehicles that operate in extreme conditions. Mechanical fan clutches can move more air than most electric fans and don’t depend on electrical system reliability.

Upgraded Clutch Options

Upgrading to a heavy-duty or severe-duty fan clutch can provide improved cooling and longevity for demanding applications. These upgrades typically cost $50-150 more than standard replacement clutches but offer enhanced performance for towing, commercial use, or high-performance applications.

Heavy-duty clutches feature improved internal components, larger working surfaces, and enhanced thermal springs that provide more aggressive engagement characteristics. They’re ideal for vehicles that regularly operate under high loads or in challenging conditions.

Severe-duty clutches represent the ultimate in mechanical fan clutch technology, with the largest working surfaces and most aggressive engagement characteristics available. They’re designed for commercial vehicles, emergency services, and extreme-duty applications where cooling is critical.

Consider your vehicle’s intended use when selecting clutch upgrades. Standard clutches are adequate for normal passenger car use, while commercial vehicles and those used for towing benefit significantly from heavy-duty alternatives. For guidance on heavy-duty applications, explore our Construction And Equipment resources for commercial vehicle considerations.

Cost-Effective Maintenance

Preventive Maintenance Strategies

Regular inspection and maintenance can significantly extend fan clutch life and prevent unexpected failures. Monthly visual inspections for leaks, damage, or unusual wear patterns take only a few minutes but can identify problems before they cause breakdowns.

Maintaining proper cooling system condition reduces fan clutch workload and extends service life. Clean radiators, proper coolant levels, and functioning thermostats reduce the frequency and intensity of fan clutch engagement, minimizing wear and extending service intervals.

Address cooling system problems promptly to prevent fan clutch overwork. A clogged radiator or failing thermostat forces the fan clutch to work harder and more frequently, accelerating wear and reducing service life.

Keep detailed maintenance records including fan clutch inspection dates, performance observations, and any symptoms noted. This documentation helps identify developing problems and provides valuable information for service providers if professional repair becomes necessary.

Professional Service Scheduling

Consider coordinating fan clutch service with other cooling system maintenance to maximize efficiency and minimize costs. Many shops offer package deals for comprehensive cooling system service that include multiple components at reduced combined labor costs.

Schedule fan clutch inspection during routine maintenance visits when the vehicle is already being serviced. Most inspections can be performed quickly during oil changes or other routine service, identifying problems before they cause breakdowns.

Plan fan clutch replacement during moderate weather conditions when cooling system demands are lower. This timing reduces the urgency of repair and allows more flexibility in scheduling and service provider selection.

For vehicles used in demanding applications such as those found in Agriculture And Equipment, consider more frequent inspection intervals and proactive replacement based on operating hours rather than waiting for symptoms to develop.

Extending Fan Clutch Life Through Proper Maintenance

Preventive maintenance significantly extends fan clutch service life while improving overall cooling system reliability. Understanding proper maintenance procedures and implementing regular inspection schedules helps avoid unexpected failures and reduces long-term ownership costs.

Regular Inspection Protocols

Monthly Visual Checks

Establish a monthly inspection routine that includes visual examination of the fan clutch and surrounding components. Look for oil leaks around the clutch hub, which appear as dark streaks radiating outward from the center due to centrifugal force. Early detection of leaks allows for planned replacement rather than emergency repair.

Inspect the thermal spring (if equipped) for proper positioning, corrosion, or damage. The spring should be securely mounted and show no signs of displacement or deterioration. A damaged or missing spring prevents proper temperature response and reduces cooling effectiveness.

Check fan blade condition for cracks, chips, or other damage that could affect balance and performance. Damaged blades cause vibration that accelerates clutch wear and can lead to catastrophic failure if blades separate during operation.

Examine belt condition and alignment, as improper belt tension or misaligned pulleys can cause excessive clutch wear. A properly maintained belt drive system is essential for optimal fan clutch operation and longevity.

Seasonal Maintenance Tasks

Prepare your cooling system for summer operation by performing comprehensive inspections before hot weather arrives. Clean the radiator exterior to remove debris that restricts airflow, check coolant levels and condition, and verify proper fan clutch operation through thermal testing.

During winter months, pay attention to engine warm-up characteristics. A properly functioning fan clutch should allow the engine to reach operating temperature within a reasonable time. Extended warm-up periods may indicate a stuck-engaged clutch that prevents proper heat retention.

Consider the impact of seasonal driving patterns on fan clutch operation. Summer stop-and-go traffic and towing place higher demands on the cooling system, while winter highway driving may allow the clutch to operate at minimal engagement levels for extended periods.

Clean the engine bay regularly to prevent debris accumulation around cooling system components. Leaves, dirt, and other debris can interfere with airflow and affect fan clutch temperature sensing, leading to improper operation.

Best Practices for Longevity

Operating Recommendations

Allow proper engine warm-up before heavy loads or high-speed operation. Cold engines with thick oil and closed thermostats don’t provide optimal conditions for fan clutch operation, and immediate heavy loading can cause unnecessary wear.

Avoid extended idling when possible, as this operating condition places maximum demand on the fan clutch while providing minimal cooling airflow. If extended idling is necessary, monitor temperature gauges closely and ensure the fan clutch engages properly to prevent overheating.

During highway driving, pay attention to fan noise levels. Properly functioning clutches should disengage almost completely at highway speeds, reducing noise and power consumption. Constant fan noise at highway speeds indicates clutch problems that require attention.

Be aware of environmental factors that affect cooling system operation. Dusty conditions, high ambient temperatures, and heavy loads all increase cooling system demands and accelerate fan clutch wear. Adjust maintenance intervals accordingly for severe operating conditions.

Professional Service Integration

Coordinate fan clutch maintenance with water pump service, as these components are closely related and often share mounting hardware. When water pump replacement becomes necessary, consider replacing the fan clutch simultaneously to prevent future access issues and ensure compatibility.

Include fan clutch inspection in routine cooling system service appointments. Most professional technicians can evaluate fan clutch condition during routine maintenance without additional labor charges, providing early warning of developing problems.

Schedule comprehensive cooling system service at manufacturer-recommended intervals, typically every 2-3 years or 30,000-50,000 miles. This service should include coolant replacement, thermostat inspection, and fan clutch evaluation to ensure all components work together effectively.

Maintain detailed service records that include fan clutch inspection results, performance observations, and any maintenance performed. This documentation helps identify trends and provides valuable information for future service decisions.

For comprehensive vehicle maintenance guidance, explore our Vehicle Care Tips section, which covers essential maintenance practices that support overall cooling system health and longevity.

Professional Service vs. DIY Repair

Deciding between professional service and DIY repair requires honest assessment of your skills, available time, and comfort level with cooling system components. While fan clutch replacement isn’t the most complex automotive repair, it does involve critical cooling system components that demand respect and proper procedures.

DIY Capability Assessment

Suitable DIY Scenarios

Fan clutch replacement is suitable for DIY mechanics with intermediate skills and proper tools. If you’re comfortable working with belt-driven accessories, have successfully performed similar repairs, and possess the specific tools required for your application, DIY replacement can save significant money.

Consider DIY repair if you have adequate workspace, proper lighting, and sufficient time to complete the job without rushing. Fan clutch replacement requires careful attention to detail and proper torque specifications, making a rushed job potentially dangerous and ineffective.

DIY repair makes most sense when you can obtain quality replacement parts at reasonable prices and have access to manufacturer service information for your specific application. Generic procedures may not account for the unique requirements of your vehicle.

Evaluate your comfort level with safety procedures and willingness to follow manufacturer specifications exactly. Fan clutch installation affects critical cooling system operation, making proper procedures essential for safe and effective repair.

Professional Service Indicators

Seek professional service if you’re uncomfortable working around hot engines or pressurized cooling systems. These components can cause serious injury if handled improperly, and professional technicians have the experience and equipment to work safely.

Professional service is recommended for electronic fan clutches that require scan tool diagnosis and PCM programming. These systems often involve complex electrical circuits and computer controls that require specialized knowledge and equipment.

Consider professional service if your vehicle is still under warranty, as improper DIY repair could void coverage for related components. Warranty considerations may make professional service more cost-effective despite higher initial costs.

If time constraints make DIY repair impractical, professional service ensures the job is completed quickly and correctly. Most shops can complete fan clutch replacement in a few hours, getting you back on the road with minimal downtime.

Finding Qualified Service

Service Provider Selection

Look for service providers with specific cooling system experience and ASE certification in engine performance or heating and air conditioning. These credentials indicate specialized knowledge that’s valuable for cooling system repairs.

Ask about diagnostic capabilities and whether the shop can perform proper fan clutch testing before replacement. Shops that offer comprehensive testing can verify the problem and ensure you’re not paying for unnecessary repairs.

Inquire about parts quality and warranty coverage for both parts and labor. Quality shops stand behind their work and use reputable parts that provide reliable service life.

Check online reviews and ask for references from other customers who’ve had cooling system work performed. Cooling system repairs require attention to detail, and customer feedback can provide insight into shop quality and reliability.

Service Communication Tips

Document all symptoms you’ve observed, including when they occur, how long they’ve been present, and any patterns you’ve noticed. This information helps technicians diagnose problems more efficiently and accurately.

Provide maintenance history for your cooling system, including recent service, parts replacement, and any ongoing issues. This background information helps technicians understand your vehicle’s condition and potential related problems.

Ask for explanation of diagnostic procedures and findings before authorizing repairs. Understanding what’s wrong and why helps you make informed decisions about repair options and future maintenance needs.

Request cost estimates for both repair and preventive maintenance options. Many cooling system problems affect multiple components, and addressing related issues during initial repair can save money and prevent future problems.

For additional support and technical questions, Repairs Advisor offers comprehensive resources through our contact form and help center, where experienced technicians can provide guidance for your specific situation.

Cooling Fan Clutch Maintenance: Your Engine’s Silent Guardian

The cooling fan clutch serves as an often-overlooked guardian of your engine’s health, automatically adjusting cooling capacity to match operating demands while saving fuel and reducing noise. Understanding its operation, recognizing failure symptoms, and performing proper maintenance are essential skills for any vehicle owner or technician serious about engine reliability and longevity.

Critical Points Summary

Early symptom recognition is your first line of defense against expensive engine damage. Engine overheating at idle, excessive fan noise, poor performance, and visible leaks all indicate fan clutch problems that require attention. Ignoring these symptoms can lead to catastrophic engine failure costing thousands of dollars in repairs.

Professional diagnostic procedures provide accurate problem identification and prevent unnecessary parts replacement. The thermal engagement test, visual inspections, and performance measurements described in this guide offer reliable methods for confirming fan clutch condition and determining appropriate repair strategies.

Quality parts and proper installation procedures are essential for reliable repairs and optimal performance. Whether performing DIY repair or selecting professional service, insist on quality components and adherence to manufacturer specifications for torque, alignment, and safety procedures.

Cost-effective maintenance through regular inspections and preventive care significantly extends fan clutch service life and prevents unexpected failures. Monthly visual checks, seasonal maintenance tasks, and coordination with other cooling system service provide maximum value and reliability.

Action Steps for Vehicle Owners

Establish regular inspection schedules that include monthly visual checks and seasonal comprehensive evaluations. Early problem detection allows for planned repairs rather than emergency service, saving money and preventing inconvenient breakdowns.

Document your cooling system’s performance characteristics and maintenance history. Understanding normal operation helps you recognize problems early and provides valuable information for service providers when professional repair becomes necessary.

Address cooling system problems promptly rather than waiting for complete failure. Fan clutch problems typically worsen gradually, and early intervention prevents more expensive repairs and potential engine damage.

Invest in quality repairs and parts when service becomes necessary. Cheap parts and shortcuts may save money initially but often result in premature failure and additional repair costs that exceed the savings from quality components and proper procedures.

Final Safety Reminders

Never ignore engine overheating symptoms or attempt to operate a vehicle with cooling system problems. Engine damage from overheating occurs quickly and can result in complete engine failure requiring replacement rather than repair.

Always prioritize safety when working on cooling system components. Hot engines, pressurized coolants, and moving fan blades can cause serious injury. When in doubt, seek professional assistance rather than risking personal safety or expensive mistakes.

Professional consultation is recommended for complex problems, electronic systems, or when you’re uncomfortable with diagnostic procedures. Experienced technicians have the tools, knowledge, and experience to diagnose problems accurately and perform repairs safely.

Maintain emergency procedures and contacts for cooling system failures. Know how to safely handle overheating situations and have contact information for reliable towing and repair services to minimize damage and inconvenience when problems occur.

For comprehensive information about related cooling system components and maintenance procedures, explore our extensive library of technical guides. Our resources cover everything from basic maintenance to complex repairs, helping you maintain your vehicle’s cooling system for optimal performance and reliability.

Whether you’re maintaining a daily driver, managing a fleet of commercial vehicles, or caring for specialized agricultural equipment, understanding cooling fan clutch operation and maintenance is essential for reliable operation and long service life. The time invested in learning proper procedures and performing regular maintenance pays dividends in reduced repair costs, improved reliability, and peace of mind knowing your cooling system will perform when needed most.

Your cooling fan clutch may be a small component in your vehicle’s complex systems, but its role in protecting your engine investment makes it worthy of attention and care. By following the guidance in this article and maintaining a proactive approach to cooling system care, you’ll ensure your engine’s silent guardian continues protecting your investment for years to come.