Just like your home, your vehicle has a fuse box – or often, multiple fuse boxes. These critical components house the fuses and sometimes circuit breakers that act as the guardians of your car’s intricate electrical circuits. Each fuse is designed to protect a specific electrical component (like your radio, headlights, or power windows) from damage due to an overload or short circuit. If too much current flows through a circuit, the fuse’s thin wire melts, breaking the circuit and preventing more serious damage to the wiring or the component itself.

What Is a Car Fuse Box and Why It’s Critical for Your Vehicle

A car fuse box serves as the central nervous system for your vehicle’s electrical protection. This essential component houses multiple fuses and relays that protect individual electrical circuits from damage caused by overcurrent conditions, short circuits, and component failures.

Primary Functions of the Automotive Fuse Box

The fuse box performs several critical functions that keep your vehicle’s electrical systems operating safely and reliably. Circuit protection represents the primary function, where each fuse acts as a sacrificial component designed to fail before expensive electrical components suffer damage. When excessive current flows through a circuit, the fuse element melts or breaks, immediately stopping current flow and protecting downstream components.

Overcurrent prevention occurs when electrical loads exceed safe operating parameters. Without proper fuse protection, excessive current could cause wiring to overheat, leading to fires or complete system failures. The fuse box ensures that each circuit receives only the appropriate amount of electrical current for safe operation.

System isolation capabilities allow technicians and vehicle owners to disable specific electrical systems for maintenance or troubleshooting without affecting other vehicle functions. This targeted approach prevents unnecessary system shutdowns and simplifies diagnostic procedures.

Component damage prevention represents perhaps the most valuable function, as replacing a $2 fuse costs significantly less than repairing a $500 electronic control module. The fuse box acts as an electrical insurance policy, protecting expensive components from voltage spikes, short circuits, and other electrical anomalies.

Types of Automotive Fuse Boxes

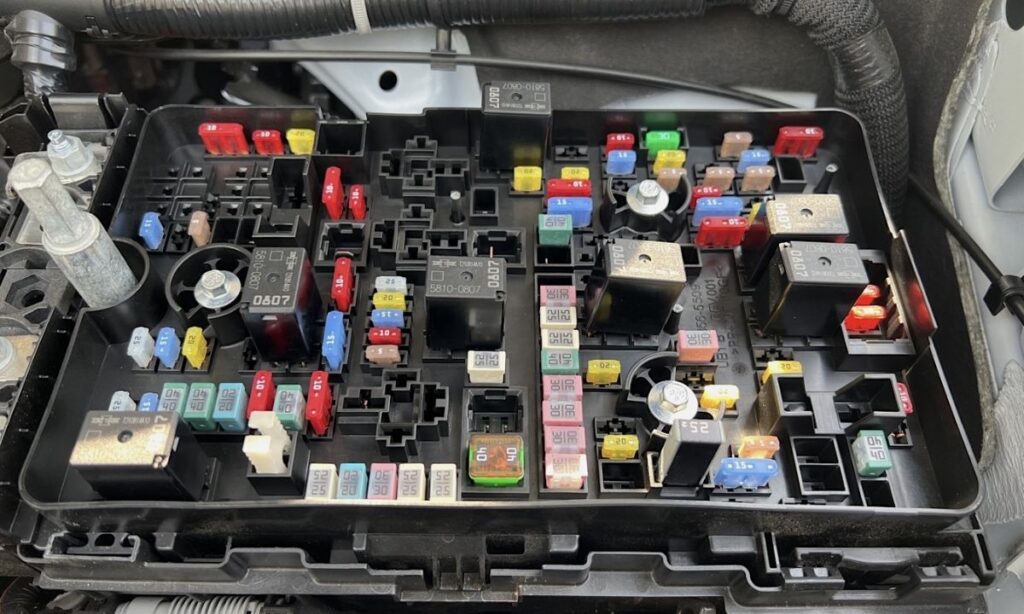

Most vehicles contain multiple fuse boxes strategically located throughout the vehicle. The engine compartment fuse box typically houses high-amperage fuses protecting major systems like the starter, alternator, cooling fans, and fuel injection system. This primary fuse box often contains the largest fuses and highest-rated circuits.

The interior or cabin fuse box usually protects convenience and comfort systems including interior lighting, radio, power windows, and dashboard instruments. These circuits typically require lower amperage ratings and smaller fuses.

Some vehicles include a trunk or rear fuse box that protects tail lights, trailer connections, and rear electrical accessories. This configuration helps distribute electrical loads and reduces wiring complexity.

Specialized fuse boxes may exist for specific systems like hybrid battery management, advanced driver assistance systems, or aftermarket electrical modifications. These specialized protection systems often require unique fuses and professional service procedures.

How Car Fuse Boxes Work: The Science Behind Electrical Protection

Understanding the fundamental principles behind fuse box operation helps vehicle owners make informed decisions about maintenance and repairs. The science involves basic electrical concepts that apply to all automotive electrical systems.

Basic Electrical Protection Principles

Electrical current flows through conductors following the path of least resistance. Under normal operating conditions, current flows through electrical components at safe levels determined by the component’s design specifications. However, overcurrent conditions can occur due to component failures, short circuits, or excessive electrical loads.

Fuse element composition varies depending on the fuse type and intended application. Most automotive fuses contain a thin metal strip or wire made from materials like zinc, copper, silver, or aluminum alloys. These materials have specific melting points and electrical characteristics that determine the fuse’s response time and current rating.

Circuit interruption mechanics involve the physical destruction of the fuse element when current exceeds safe levels. The fuse element heats up due to electrical resistance, and excessive current causes the element to melt or vaporize, creating an open circuit that stops current flow immediately.

Voltage and amperage considerations affect fuse selection and application. Automotive fuses must withstand the vehicle’s 12-volt electrical system while providing accurate protection at specific amperage levels. Higher amperage fuses protect circuits with greater electrical loads, while lower amperage fuses protect sensitive electronic components.

Fuse Box Components and Architecture

Modern fuse boxes contain sophisticated components beyond simple fuses. Fuse slots and ratings provide organized mounting points for individual fuses, with each slot clearly labeled for easy identification. The fuse box design ensures proper electrical connections while allowing easy fuse removal and replacement.

Relay positions house electromagnetic switches that control high-current devices using low-current signals. Relays protect sensitive electronic control modules from high electrical loads while enabling precise system control. Common relay applications include starter motors, cooling fans, and fuel pumps.

Circuit identification systems help technicians and vehicle owners locate specific circuits quickly. Most fuse boxes include detailed diagrams showing fuse locations, amperage ratings, and protected components. These identification systems prove invaluable during troubleshooting and maintenance procedures.

Power distribution pathways route electrical current from the battery and alternator to individual vehicle systems. The fuse box design minimizes voltage drop while providing convenient access points for electrical testing and component replacement.

Common Types of Automotive Fuses and Their Applications

Automotive fuses come in various sizes, shapes, and amperage ratings to accommodate different electrical loads and space constraints. Understanding fuse types helps ensure proper replacement and system protection.

Blade Fuses (Most Common)

Mini fuses (ATO/ATC) represent the most common automotive fuse type, typically rated from 2 to 30 amperes. These compact fuses protect low to moderate electrical loads including interior lighting, radio systems, and electronic control modules. The standardized design ensures compatibility across different vehicle manufacturers.

Standard fuses handle slightly higher amperage ratings from 1 to 40 amperes and protect systems like power windows, air conditioning, and charging systems. These fuses use the same blade-style design as mini fuses but feature larger physical dimensions for increased current capacity.

Maxi fuses protect high-amperage circuits from 30 to 80 amperes, commonly used for cooling fans, starter circuits, and main power distribution. The larger physical size accommodates thicker fuse elements capable of handling substantial electrical loads safely.

Mega fuses handle the highest amperage ratings from 80 to 200+ amperes, protecting major electrical systems like hybrid battery circuits, electric vehicle charging systems, and high-output alternator circuits. These specialized fuses require careful handling and professional replacement procedures.

Cartridge and Specialty Fuses

Glass tube fuses appear in older vehicles and some specialized applications. These fuses contain a visible fuse element inside a glass tube, making visual inspection straightforward. However, glass fuses are fragile and less reliable than modern blade-style fuses.

Ceramic fuses withstand high-temperature environments and provide superior performance in demanding applications. These fuses cost more than standard types but offer enhanced reliability and longevity in extreme conditions.

Reset-able fuses or circuit breakers automatically restore circuit operation after cooling down from an overcurrent event. While convenient, these devices may not provide adequate protection for sensitive electronic components and should only be used in appropriate applications.

Fuse Rating and Color Coding Standards

Amperage identification systems help ensure proper fuse selection and replacement. Most automotive fuses display their amperage rating clearly on the fuse body, typically molded into the plastic housing or printed on a label.

Universal color coding provides quick visual identification of fuse ratings, though not all manufacturers follow identical color schemes. Common color codes include tan (5A), red (10A), blue (15A), yellow (20A), and green (30A), but always verify the actual amperage rating marked on the fuse.

Reading fuse markings correctly requires understanding manufacturer-specific marking systems. Some fuses display amperage ratings in numbers, while others use letter codes or symbols. When replacing fuses, always match the exact amperage rating specified by the vehicle manufacturer.

Understanding your vehicle’s electrical and lights systems provides essential background knowledge for fuse box maintenance and troubleshooting procedures.

Locating Your Vehicle’s Fuse Box: A Step-by-Step Guide

Finding your vehicle’s fuse box represents the first step in any electrical troubleshooting or maintenance procedure. Most vehicles have multiple fuse box locations, each serving specific electrical systems.

Primary Fuse Box Locations by Vehicle Type

Passenger cars typically mount the main fuse box in the engine compartment near the battery or along the firewall. This location provides easy access for high-amperage circuits while protecting the fuse box from passenger compartment moisture and debris. Some passenger cars also feature a secondary fuse box under the dashboard on the driver’s side.

SUVs and trucks often distribute fuses across multiple locations due to their larger size and diverse electrical systems. The primary fuse box usually resides in the engine compartment, with secondary boxes located under the dashboard, behind interior panels, or in the cargo area. Larger vehicles may have specialized fuse boxes for trailer connections, rear entertainment systems, or auxiliary power outlets.

Hybrid and electric vehicles require special considerations due to high-voltage electrical systems and additional safety protocols. These vehicles often feature multiple fuse boxes with specific access procedures and safety requirements. Never attempt to service hybrid or electric vehicle fuse boxes without proper training and safety equipment.

Using Your Owner’s Manual and Fuse Box Diagrams

Interpreting fuse box labels requires careful attention to manufacturer-specific terminology and abbreviations. Most fuse boxes include printed diagrams showing fuse locations, amperage ratings, and protected circuits. These diagrams use standardized symbols and abbreviations that may vary between manufacturers.

Understanding circuit diagrams helps identify which components connect to specific fuses. Circuit diagrams show electrical pathways, component relationships, and system interdependencies. This information proves valuable when troubleshooting complex electrical problems that affect multiple systems.

Cross-referencing component functions ensures accurate fuse identification and replacement. When experiencing electrical problems, use the owner’s manual to identify which fuse protects the affected system, then locate that fuse in the fuse box using the provided diagram.

Diagnosing Car Fuse Box Problems: Professional Troubleshooting Methods

Effective fuse box diagnosis requires systematic approaches and proper safety procedures. Professional troubleshooting methods help identify problems quickly while preventing additional damage to electrical systems.

Common Symptoms of Fuse Box Issues

Multiple systems failing simultaneously often indicates main fuse or power distribution problems. When several unrelated electrical systems stop working at the same time, check high-amperage fuses and main power connections before investigating individual circuits.

Intermittent electrical problems may suggest loose connections, corroded terminals, or partially failed fuses. These conditions create unreliable electrical connections that cause systems to work sporadically or fail under specific operating conditions.

Complete electrical system shutdown typically results from main fuse failure, battery problems, or major wiring faults. This serious condition requires immediate attention and may indicate underlying electrical system damage that needs professional diagnosis.

Burning smells or visible damage represent serious safety concerns that require immediate investigation. Overheated wiring, melted fuse boxes, or burned components indicate dangerous conditions that could lead to vehicle fires or electrical hazards.

Corrosion and moisture damage commonly affect fuse boxes in older vehicles or those exposed to harsh environmental conditions. Corroded terminals and moisture infiltration create electrical resistance and unreliable connections that cause various electrical problems.

Visual Inspection Techniques

Safety preparation procedures must precede any fuse box inspection work. Disconnect the battery negative terminal, ensure the engine is off and cool, and remove jewelry or loose clothing that could create electrical hazards. Work in well-lit conditions and have fire extinguishing equipment readily available.

Identifying blown fuses visually requires careful examination of the fuse element. Blade-style fuses typically have visible fuse elements that appear intact in good fuses and broken or discolored in blown fuses. Glass tube fuses show obvious breaks in the internal wire element when failed.

Checking for corrosion and damage involves inspecting fuse terminals, wiring connections, and the fuse box housing. Look for green or white corrosion deposits, blackened or melted plastic, and damaged or loose wire connections. Document any damage with photographs before beginning repairs.

Assessing wire connection integrity requires gentle manipulation of wire connections while observing for loose or damaged terminations. Properly connected wires should not move or spark when lightly manipulated. Loose connections often show signs of overheating or arcing damage.

Using Multimeter for Electrical Testing

Continuity testing procedures verify that electrical pathways remain intact and functional. Set the multimeter to continuity or resistance mode, then test across fuse terminals to confirm the fuse element conducts electricity properly. A good fuse shows near-zero resistance, while a blown fuse shows infinite resistance.

Voltage drop measurements identify excessive electrical resistance in circuits and connections. Connect the multimeter across suspect connections or components while the circuit operates under load. Excessive voltage drop indicates high resistance that reduces system performance and may cause component failures.

Amperage draw testing measures actual current consumption compared to circuit specifications. Use a clamp-on ammeter or multimeter with current measurement capability to verify that circuits operate within design parameters. Excessive current draw indicates short circuits or component failures.

Resistance measurements help identify faulty components and poor connections. Measure resistance across individual components and compare results to manufacturer specifications. High resistance in connections or components indicates deterioration that affects system performance.

For comprehensive electrical troubleshooting guidance, explore our diagnostics and troubleshooting resources that cover systematic diagnostic approaches for various vehicle systems.

Step-by-Step Fuse Box Inspection and Testing

Systematic fuse box inspection prevents overlooked problems and ensures thorough evaluation of electrical system condition. Following established procedures reduces diagnostic time and improves repair success rates.

Safety Protocols Before Beginning Work

Battery disconnection procedures represent the first and most critical safety step. Remove the negative battery terminal first, then the positive terminal if complete electrical isolation is required. Wait at least 10 minutes after disconnection to allow capacitors and electronic modules to discharge completely.

Personal protective equipment requirements include safety glasses, insulated gloves, and non-conductive tools. Avoid wearing metal jewelry, loose clothing, or synthetic fabrics that generate static electricity. Work in dry conditions and ensure adequate lighting for detailed inspection work.

Fire safety considerations require readily available fire extinguishing equipment appropriate for electrical fires. Never use water on electrical fires, as water conducts electricity and may cause electrocution or spread the fire. Keep a Class C fire extinguisher within easy reach during electrical work.

Workspace preparation involves organizing tools, documentation, and replacement parts before beginning work. Clear the work area of unnecessary items and ensure adequate space for safe tool operation. Have vehicle service manuals and fuse box diagrams readily available for reference.

Systematic Fuse Testing Process

Visual inspection methodology begins with careful examination of the entire fuse box for obvious damage, corrosion, or overheating. Check the fuse box housing for cracks, melted areas, or water damage. Inspect all visible wiring for damage, chafing, or signs of overheating.

Individual fuse removal and testing requires proper fuse removal tools to prevent damage to fuse terminals or the fuse itself. Remove one fuse at a time, test it using appropriate methods, and replace it before proceeding to the next fuse. This systematic approach prevents confusion and ensures all fuses receive proper evaluation.

Circuit functionality verification involves testing the electrical system protected by each fuse to ensure proper operation. After replacing a suspect fuse, operate the protected system to verify restoration of normal function. Non-functioning systems despite good fuses indicate problems beyond the fuse box.

Documentation and labeling systems help track inspection progress and results. Create a simple checklist showing fuse locations, test results, and any problems discovered. This documentation proves valuable for future maintenance and helps communicate problems to professional technicians if needed.

Advanced Diagnostic Procedures

Load testing techniques verify that circuits operate properly under normal operating conditions. Connect appropriate electrical loads to test circuits while monitoring voltage, current, and system performance. Load testing reveals problems that may not appear during no-load testing conditions.

Circuit tracing methods help identify the complete electrical pathway from power source to ground return. Use wiring diagrams and test equipment to follow electrical circuits through various components and connection points. Circuit tracing helps locate intermittent problems and hidden damage.

Relay testing procedures verify proper operation of electromagnetic switches that control high-current devices. Test relay coil resistance, contact operation, and switching characteristics using appropriate test equipment. Faulty relays often cause intermittent problems that appear to be fuse-related.

Power distribution verification ensures that electrical power reaches all fuse box terminals at proper voltage levels. Test main power feeds, ground connections, and internal fuse box distribution systems. Poor power distribution affects multiple circuits and may cause seemingly random electrical problems.

Common Car Fuse Box Problems and Solutions

Understanding common fuse box problems helps vehicle owners recognize symptoms early and take appropriate corrective action. Many fuse box issues result from environmental factors, age, or improper maintenance practices.

Blown Fuses: Causes and Prevention

Overloaded circuits represent the most common cause of blown fuses. This condition occurs when electrical loads exceed the circuit’s design capacity, often due to multiple high-power accessories operating simultaneously or aftermarket equipment installations that draw excessive current.

Short circuits and ground faults create direct electrical pathways that bypass normal circuit resistance. These conditions cause massive current flow that immediately destroys fuses and may damage other electrical components. Short circuits often result from damaged wiring, component failures, or moisture infiltration.

Component failures causing overcurrent happen when electrical devices malfunction and draw excessive current. Failed motors, heating elements, or electronic control modules may develop internal shorts that cause repeated fuse failures. These problems require component replacement rather than simply replacing fuses.

Age-related fuse degradation affects older vehicles where fuses have experienced repeated thermal cycling and environmental exposure. Old fuses may fail at currents below their rated capacity due to deteriorated fuse elements or corrosion at connection points.

Corrosion and Environmental Damage

Moisture infiltration problems commonly affect fuse boxes in humid climates or vehicles exposed to flooding. Water creates electrical conductivity between circuits and promotes corrosion that damages connections and components. Prevention involves maintaining fuse box seals and addressing water leaks promptly.

Salt and chemical corrosion accelerates in coastal areas or regions where road salt is used extensively. These corrosive substances attack metal components and create electrical resistance that affects system performance. Regular cleaning and protective treatments help minimize corrosion damage.

Temperature-related damage occurs in extreme hot or cold conditions that exceed component design limits. High temperatures may melt plastic components or cause expansion damage, while extreme cold can make plastic brittle and prone to cracking.

Cleaning and protection strategies involve regular inspection and maintenance to prevent minor problems from becoming major repairs. Use appropriate electrical contact cleaners, protective sprays, and moisture-absorbing compounds to maintain fuse box condition.

For additional information about common electrical problems, visit our common problem section that covers typical automotive electrical issues and their solutions.

Loose Connections and Poor Contact

Connection point maintenance requires periodic inspection and cleaning of all electrical connections in the fuse box. Loose connections create electrical resistance that generates heat and may cause component failures or fire hazards.

Terminal cleaning procedures involve removing corrosion and debris from electrical connection points using appropriate cleaning materials. Use fine abrasives, electrical contact cleaners, and protective coatings to restore proper electrical conductivity.

Proper installation techniques ensure that fuses and relays make reliable electrical contact with their mounting terminals. Avoid forcing components into place, and ensure proper orientation and full insertion for optimal performance.

Contact enhancement methods may involve applying electrical contact improvement compounds or replacing worn terminals and connectors. These preventive measures help maintain reliable electrical connections and prevent future problems.

Fuse Replacement: Professional Procedures and Safety Guidelines

Proper fuse replacement procedures ensure safe and effective repair of electrical problems. Following established guidelines prevents damage to electrical systems and reduces the risk of personal injury.

Selecting the Correct Replacement Fuse

Amperage rating importance cannot be overstated when selecting replacement fuses. Using a fuse with higher amperage rating than specified may allow dangerous overcurrent conditions that damage expensive electrical components or create fire hazards. Always match the exact amperage rating specified by the vehicle manufacturer.

Physical size compatibility ensures proper fit and electrical contact in fuse box terminals. Different fuse types have specific physical dimensions that affect mounting and electrical connections. Using incompatible fuse sizes may result in poor electrical contact or physical damage to the fuse box.

Type and style matching involves selecting fuses with identical characteristics to the original equipment. While different fuse types may have similar amperage ratings, they may have different response characteristics or physical requirements that affect system operation.

Never use higher-rated fuses as a temporary solution to repeated fuse failures. Higher-rated fuses may not protect electrical components adequately and could allow damage to occur before the fuse fails. Address the underlying cause of fuse failures rather than masking the problem with inappropriate fuses.

Proper Fuse Installation Techniques

Safe removal procedures require appropriate tools and careful handling to prevent damage to fuse terminals or the fuse itself. Use plastic fuse pullers or needle-nose pliers with insulated handles to grasp fuses firmly without applying excessive force.

Contact point preparation may involve cleaning fuse terminals and connection points before installing new fuses. Remove any corrosion, debris, or moisture that could affect electrical contact quality.

Installation verification ensures that new fuses seat properly and make reliable electrical contact. Gently manipulate installed fuses to verify secure mounting without excessive looseness or binding.

System testing protocols involve operating the protected electrical system to verify proper function after fuse replacement. Test all system functions and monitor for proper operation under normal load conditions.

When NOT to Replace a Fuse

Repeated fuse failures indicate underlying electrical problems that require professional diagnosis and repair. Continuing to replace fuses without addressing root causes may result in electrical damage or safety hazards.

Underlying electrical problems such as short circuits, component failures, or wiring damage must be resolved before fuse replacement will provide lasting repairs. Professional diagnostic equipment and expertise may be required to identify and correct these problems.

Safety system involvement requires professional attention when fuses protect critical safety systems like airbags, anti-lock brakes, or stability control. These systems have specific diagnostic and repair requirements that exceed typical DIY capabilities.

Professional diagnosis requirements apply when multiple related systems fail, electrical problems occur repeatedly, or safety concerns exist. Professional technicians have specialized equipment and training necessary for complex electrical system diagnosis and repair.

Preventive Maintenance for Car Fuse Boxes

Regular preventive maintenance extends fuse box life and prevents electrical problems that could leave you stranded or require expensive repairs. Establishing maintenance routines helps identify problems early when repairs are simpler and less costly.

Regular Inspection Schedules

Monthly visual checks should include examining fuse boxes for obvious signs of damage, corrosion, or moisture infiltration. Look for melted plastic, burnt smells, or visible corrosion that indicates developing problems.

Annual detailed inspections involve more thorough evaluation of fuse box condition including removal and testing of suspect fuses, cleaning of terminals, and verification of proper operation. Annual inspections help identify problems before they cause system failures.

Seasonal maintenance considerations may require additional attention in harsh climates or severe operating conditions. Vehicles exposed to salt, moisture, or extreme temperatures may need more frequent inspection and maintenance.

High-mileage vehicle attention becomes increasingly important as vehicles age and electrical systems accumulate wear and environmental damage. Older vehicles may require more frequent fuse box maintenance and component replacement.

For comprehensive maintenance guidance, explore our vehicle care tips section that covers preventive maintenance procedures for all vehicle systems.

Environmental Protection Strategies

Moisture prevention techniques involve maintaining proper seals and drainage systems that keep fuse boxes dry. Address water leaks promptly and ensure that fuse box covers and seals remain intact and functional.

Corrosion inhibitor applications help protect metal components from environmental damage. Use appropriate electrical protectants and moisture-displacing compounds designed for automotive electrical systems.

Seal and gasket maintenance requires periodic inspection and replacement of weatherstripping and seals that protect fuse boxes from environmental contamination. Replace damaged seals promptly to prevent moisture and debris infiltration.

Temperature management may involve relocating aftermarket equipment or improving ventilation to reduce excessive heat buildup around fuse boxes. High temperatures accelerate component aging and increase failure rates.

Electrical System Load Management

Avoiding circuit overloads requires understanding electrical system capacity and managing accessory installations appropriately. Calculate total electrical loads and ensure they remain within system design limits.

Aftermarket accessory considerations should include proper circuit protection and installation techniques that don’t compromise existing electrical systems. Use appropriate fuse ratings and wiring techniques for all electrical modifications.

Power consumption monitoring helps identify systems that draw excessive current or operate inefficiently. Monitor battery charging systems and electrical loads to ensure proper system operation.

Electrical system upgrades may be necessary when adding high-power accessories or converting to modern electrical components. Consult qualified technicians for major electrical system modifications.

Modern Fuse Box Technology and Innovations

Automotive electrical systems continue evolving with advanced technologies that provide enhanced protection, monitoring, and diagnostic capabilities. Understanding modern fuse box innovations helps vehicle owners appreciate these systems and use them effectively.

Smart Fuse Box Systems

Electronic fuse monitoring uses sensors and computer systems to monitor electrical circuit status continuously. These systems can detect developing problems before complete failures occur and provide early warning of electrical system issues.

Diagnostic communication capabilities allow fuse boxes to communicate with scan tools and diagnostic equipment. Technicians can access detailed information about electrical system status, fault history, and component performance through standardized diagnostic protocols.

Remote monitoring features may include smartphone apps or telematics systems that provide real-time electrical system status information. These features help fleet managers and vehicle owners monitor electrical system health and schedule maintenance proactively.

Integration with vehicle computers allows fuse boxes to coordinate with other vehicle systems for optimized performance and protection. Smart fuse boxes can adjust protection characteristics based on operating conditions and system requirements.

Programmable Circuit Protection

Variable amperage settings allow technicians to adjust circuit protection characteristics for specific applications or operating conditions. This flexibility improves protection accuracy and reduces nuisance fuse failures.

Adaptive protection algorithms monitor circuit behavior and adjust protection characteristics automatically based on load patterns and operating history. These systems provide optimal protection while minimizing unnecessary interruptions.

System-specific customization enables different protection strategies for various electrical systems within the same vehicle. Critical systems may receive enhanced protection while convenience systems use standard protection levels.

Future technology trends point toward increased integration, enhanced diagnostic capabilities, and improved reliability through advanced materials and design techniques.

Professional vs. DIY Fuse Box Repair: Making the Right Decision

Understanding when to attempt DIY repairs versus seeking professional assistance ensures safe and effective resolution of fuse box problems. Making appropriate decisions protects both personal safety and vehicle electrical systems.

DIY-Appropriate Tasks

Simple fuse replacement represents the most basic DIY fuse box repair that most vehicle owners can perform safely. This task requires minimal tools and technical knowledge while providing immediate resolution of many electrical problems.

Basic visual inspections help identify obvious problems like blown fuses, corrosion, or physical damage. Visual inspections require no special tools and provide valuable information for troubleshooting electrical issues.

Routine maintenance procedures including cleaning terminals, checking connections, and replacing worn components fall within typical DIY capabilities. These preventive measures help maintain fuse box condition and prevent problems.

Component testing with proper tools enables DIY diagnosis of fuse and relay operation using basic electrical test equipment. Understanding how to use multimeters and test lights safely expands DIY diagnostic capabilities.

For step-by-step repair guidance, visit our how-to section that provides detailed instructions for various automotive maintenance and repair procedures.

When to Seek Professional Help

Complex electrical diagnostics require specialized equipment and training that exceed typical DIY capabilities. Professional technicians have access to advanced diagnostic tools and manufacturer-specific information necessary for complex problem resolution.

Fuse box replacement or relocation involves extensive electrical work that requires professional expertise to ensure safe and proper installation. These procedures affect multiple vehicle systems and must be performed correctly to prevent damage or safety hazards.

Multiple system failures often indicate complex electrical problems that require systematic diagnosis and repair. Professional technicians can efficiently identify and resolve interconnected electrical issues that might confuse DIY troubleshooting efforts.

Safety system involvement requires professional attention when electrical problems affect critical safety systems. These systems have specific diagnostic and repair requirements that must be followed exactly to ensure continued safe operation.

Recurring electrical problems suggest underlying issues that require professional diagnosis and repair. Continuing DIY attempts may cause additional damage or mask serious problems that require immediate attention.

Finding Qualified Automotive Electrical Technicians

Certification requirements help identify technicians with appropriate training and expertise for electrical system work. Look for ASE (Automotive Service Excellence) certification in electrical systems or manufacturer-specific training credentials.

Shop equipment standards indicate the facility’s capability to diagnose and repair modern electrical systems. Qualified shops should have current diagnostic equipment, electrical test tools, and access to manufacturer technical information.

Experience verification involves checking references and reviewing the technician’s background with similar electrical problems. Experienced technicians can often resolve problems more efficiently and accurately than less experienced personnel.

Warranty and guarantee considerations provide protection against defective repairs and ensure accountability for work performed. Reputable shops stand behind their work and provide appropriate warranties for parts and labor.

Cost Considerations and Budgeting for Fuse Box Repairs

Understanding typical costs associated with fuse box repairs helps vehicle owners budget appropriately and make informed decisions about repair options. Cost considerations include both immediate repair expenses and long-term maintenance investments.

Typical Repair and Replacement Costs

Individual fuse replacement costs typically range from $1 to $10 per fuse depending on the fuse type and vehicle application. Standard blade fuses cost less than specialized high-amperage fuses, but labor costs may add $20 to $50 for professional installation.

Fuse box replacement expenses can range from $200 to $1,000 or more depending on vehicle complexity and fuse box location. Luxury vehicles and those with complex electrical systems typically cost more due to higher parts costs and increased labor requirements.

Labor costs for electrical diagnosis vary significantly based on problem complexity and shop rates. Simple fuse testing may cost $50 to $100, while complex electrical diagnosis can cost $300 to $500 or more depending on the time required.

Preventive maintenance investments typically cost less than emergency repairs and help prevent more expensive problems. Annual fuse box inspections and maintenance may cost $100 to $200 but can prevent much more expensive electrical system failures.

Cost-Saving Strategies

DIY maintenance capabilities enable vehicle owners to perform basic fuse box maintenance and simple repairs without professional labor costs. Learning basic electrical troubleshooting skills provides long-term cost savings and improved vehicle reliability.

Preventive care approaches help identify and address problems before they cause expensive damage or leave you stranded. Regular inspections and maintenance cost less than emergency repairs and improve overall vehicle reliability.

Quality parts selection involves choosing appropriate replacement components that provide reliable service without unnecessary expense. OEM or equivalent quality parts often provide better value than cheap alternatives that fail prematurely.

Extended warranty considerations may provide cost protection for electrical system repairs on newer vehicles. Evaluate warranty coverage carefully to understand what electrical problems are covered and any limitations or exclusions.

Safety Warnings and Critical Considerations

Electrical work on vehicles carries inherent risks that require careful attention to safety procedures and personal protection. Understanding these risks and taking appropriate precautions prevents injury and property damage.

Electrical Safety Protocols

High-voltage system awareness becomes increasingly important with hybrid and electric vehicles that operate at dangerous voltage levels. Never attempt to service these systems without proper training, equipment, and safety procedures.

Battery safety procedures prevent explosion hazards and chemical burns associated with automotive batteries. Disconnect battery terminals in the correct sequence, avoid smoking or open flames near batteries, and wear appropriate protective equipment.

Fire prevention measures include having appropriate fire extinguishing equipment readily available and understanding how to respond to electrical fires. Never use water on electrical fires, as water conducts electricity and may cause electrocution.

Personal protective equipment requirements include safety glasses, insulated gloves, and non-conductive tools. Remove metal jewelry and avoid loose clothing that could contact electrical components or become entangled in moving parts.

When to Avoid DIY Repairs

Airbag system circuits require specialized procedures and safety equipment that exceed typical DIY capabilities. Improper handling of airbag circuits can cause inadvertent deployment that results in serious injury or death.

Hybrid and electric vehicle systems operate at lethal voltage levels and require specialized training and equipment for safe service. These systems can cause electrocution even when the vehicle appears to be shut off.

Anti-lock brake system components affect critical safety functions and require proper diagnostic procedures to ensure continued safe operation. Improper repairs may compromise braking performance and create serious safety hazards.

Engine management systems control critical vehicle functions and may require specialized programming or calibration procedures after repair. Improper repairs can affect vehicle performance, emissions compliance, and safety.

Emergency Procedures

Electrical fire response requires immediate action to prevent injury and property damage. Disconnect battery power if safely possible, use appropriate fire extinguishing equipment, and evacuate the area if necessary.

System shutdown protocols help prevent electrical damage and personal injury during emergency situations. Know how to quickly disconnect electrical power and isolate affected systems safely.

Emergency contact procedures should include local emergency services and qualified automotive technicians who can provide immediate assistance with serious electrical problems.

First aid considerations may be necessary if electrical accidents result in burns, shock, or other injuries. Understand basic first aid procedures and have emergency contact information readily available.

Safety Disclaimer: Electrical work on vehicles carries inherent risks including fire, explosion, and electrocution. This information is for reference only. Always consult your vehicle’s service manual and consider professional assistance for complex electrical issues.

Professional Consultation Note: While basic fuse replacement is typically within DIY capabilities, complex electrical problems require professional diagnosis and repair. When in doubt, consult qualified automotive electrical technicians.

Understanding your car’s fuse box empowers you to handle basic electrical problems while recognizing when professional help is necessary. Regular maintenance and proper troubleshooting procedures keep your vehicle’s electrical systems operating safely and reliably. For detailed fuse box diagrams and electrical schematics specific to your vehicle, consult your manufacturer’s service manual or contact [email protected] for manual availability.

Related electrical system information can help you understand the broader context of automotive electrical systems. Learn more about why your car battery dies and what to do about it and signs of a bad or failing alternator to gain comprehensive knowledge of your vehicle’s electrical systems. For organized information about all vehicle systems, explore our [vehicle systems an