Carburetor problems can leave you stranded at the worst possible moment – but they don’t have to catch you off guard. Whether you’re dealing with a classic car that won’t start on a Sunday drive or a lawn mower that’s refusing to cooperate before the big yard work weekend, learning to spot carburetor issues early can save you time, money, and frustration.

Many drivers and equipment owners struggle to identify carburetor problems before they escalate into costly repairs or complete breakdowns. The symptoms can be subtle at first, masquerading as minor performance issues that seem to come and go. By the time the problem becomes obvious, you might be facing a more expensive repair or replacement.

This comprehensive guide will help you recognize the warning signs of carburetor problems and make informed decisions about when to tackle the issue yourself or seek professional help. We’ll walk you through visual inspection techniques, performance symptoms to watch for, and simple diagnostic tests you can perform safely at home.

Important Safety Notice: Working with fuel systems requires proper safety precautions. Always ensure adequate ventilation, keep fire extinguishers nearby, and never smoke or create sparks around fuel vapors. If you’re not comfortable working around gasoline, consult a qualified technician immediately.

Understanding Your Carburetor

What is a Carburetor and How Does it Work?

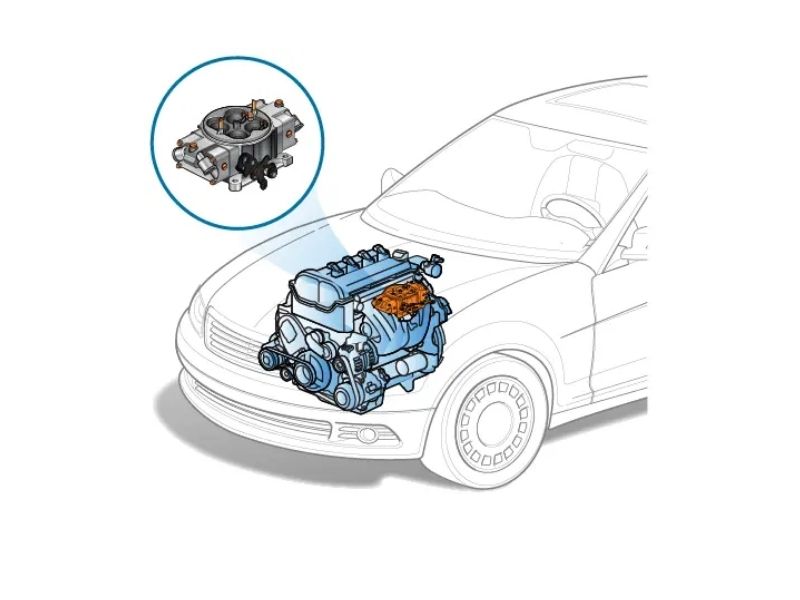

A carburetor is essentially your engine’s fuel mixer, responsible for creating the precise air-fuel mixture needed for combustion. Unlike modern fuel injection systems that use electronic controls and high-pressure pumps, carburetors rely on vacuum and mechanical principles to draw fuel from the tank and mix it with incoming air.

The process begins when air flows through the carburetor’s venturi (a narrowed section that increases air velocity). This fast-moving air creates a vacuum that draws fuel up through tiny passages called jets. The fuel mixes with the air in carefully calibrated proportions, typically around 14.7 parts air to 1 part fuel for optimal combustion.

Key components include the float bowl (which maintains a consistent fuel level), jets (precisely sized openings that control fuel flow), the needle valve (which regulates fuel entering the float bowl), and the throttle plate (which controls airflow and engine speed). Each component must work in harmony for proper engine operation.

Understanding these basics helps explain why carburetor problems often manifest as fuel mixture issues – either too rich (too much fuel) or too lean (too little fuel) – rather than complete failure.

Common Carburetor Types by Application

Single barrel carburetors are the most common type found on small engines, motorcycles, and many classic cars. They’re relatively simple to diagnose and maintain, making them ideal for DIY troubleshooting. These carburetors typically have fewer adjustments and components that can fail.

Multi-barrel carburetors (two-barrel or four-barrel) are found on larger automotive engines and provide better power and fuel economy through progressive throttle opening. However, they’re more complex to diagnose because problems can occur in one barrel while others function normally.

Small engine carburetors on lawn mowers, generators, and chainsaws are often the simplest designs but face unique challenges from seasonal storage, fuel degradation, and debris contamination. These are frequently the most DIY-friendly to diagnose and clean.

Age and complexity factors significantly impact diagnostic approaches. Older carburetors may lack emissions controls but are often easier to access and adjust. Newer carburetors with pollution control devices require more careful handling and often mandate professional service.

When Carburetors Fail: Primary Causes

Fuel contamination and deposits represent the most common cause of carburetor problems. Modern gasoline containing ethanol can attract moisture and form gummy deposits that clog jets and passages. Water in fuel can cause rust and corrosion of internal components, while dirt and debris can block critical fuel flow passages.

Gasket and seal deterioration occurs naturally over time, especially when equipment sits unused for extended periods. Dried-out gaskets allow air leaks that disrupt the precise air-fuel mixture, while deteriorated float bowl seals can cause fuel leaks and inconsistent fuel levels.

Mechanical wear and adjustment drift affect older carburetors where repeated use has worn throttle shafts, needle valves, and adjustment screws. Vibration can also cause adjustment screws to back out, changing the fuel mixture settings.

Environmental factors like temperature extremes, moisture exposure, and altitude changes can affect carburetor performance. Cold weather can cause fuel to thicken and affect mixture ratios, while high humidity can introduce moisture into the fuel system.

For detailed information about engine systems and their interactions, explore our comprehensive Engine resource library.

Visual Signs of Carburetor Problems

External Inspection Points

Fuel stains and leaks around the carburetor base are often the first visible signs of problems. Fresh fuel stains appear wet and smell strongly of gasoline, while older stains may appear as dark, gummy residue. Check around the carburetor mounting bolts, fuel bowl gasket, and fuel line connections for any signs of seepage.

Corroded or damaged linkages and connections can indicate long-term fuel exposure or general deterioration. Look for white, green, or brown corrosion on metal components, especially around the throttle linkage, choke mechanism, and fuel fittings. Damaged linkages can cause erratic throttle response or prevent proper choke operation.

Dirty or clogged air filter housing directly impacts carburetor performance by restricting airflow. A severely dirty air filter forces the carburetor to run rich, while a damaged filter allows dirt to enter the carburetor. Remove the air filter and inspect both the filter element and the housing for dirt, oil contamination, or damage.

Cracked or deteriorated fuel lines leading to the carburetor can cause fuel leaks, air leaks, or fuel starvation. Check rubber fuel lines for cracks, swelling, or soft spots that indicate deterioration. Hard, brittle fuel lines are particularly prone to cracking and should be replaced immediately.

Safety Note: Always inspect fuel systems in well-ventilated areas away from ignition sources. If you detect strong fuel odors or see active fuel leaks, stop the inspection and address the leak before continuing.

Under-Hood Observations

Black smoke from the exhaust typically indicates a rich fuel mixture where the carburetor is delivering too much fuel. This can result from a stuck choke, clogged air filter, or incorrectly adjusted fuel mixture screws. Black smoke is often accompanied by poor fuel economy and rough running.

White or blue smoke patterns can indicate different issues depending on the specific pattern. Occasional white smoke during startup might be normal condensation, but continuous white smoke could indicate coolant entering the combustion chamber. Blue smoke typically indicates oil burning, which isn’t directly carburetor-related but can affect carburetor performance.

Fuel odors and vapor visibility around the engine bay suggest fuel leaks or over-rich conditions. Fresh fuel odors indicate active leaks that require immediate attention, while stale fuel odors might indicate old fuel in the system that needs replacement.

Engine bay cleanliness around the carburetor can reveal ongoing problems. Fuel leaks often wash away normal dirt and oil, leaving clean spots on otherwise dirty surfaces. Conversely, excessive dirt buildup around the carburetor might indicate poor maintenance or air filter problems.

Dashboard and Gauge Indicators

Fuel consumption changes are often early indicators of carburetor problems. A sudden increase in fuel consumption usually indicates a rich-running condition, while improved fuel economy might paradoxically indicate a lean condition that’s reducing power output.

Temperature gauge abnormalities can result from carburetor problems affecting engine performance. A lean mixture can cause overheating, while an extremely rich mixture might cause the engine to run cooler than normal but with poor performance.

Performance loss patterns that correspond with fuel system behavior often point to carburetor issues. If performance problems worsen as the fuel tank empties or improve after refueling, the carburetor or fuel delivery system is likely involved.

For comprehensive information about small engine carburetor systems, visit our Home & Garden equipment resources.

Performance Symptoms That Signal Carburetor Issues

Starting Problems

Hard starting when cold versus warm often indicates choke system problems. If the engine starts easily when warm but struggles when cold, the automatic choke may not be closing properly or the choke adjustment may be incorrect. Conversely, if the engine starts fine when cold but is difficult to restart when warm, the choke may be sticking closed or the fuel mixture may be too rich.

Flooding symptoms occur when too much fuel enters the engine, preventing proper combustion. Signs include strong fuel odors, fuel dripping from the air cleaner or exhaust, and the engine turning over but not starting. Flooding can result from a stuck float, damaged needle valve, or excessive use of the primer or choke.

Vapor lock identification becomes apparent when the engine starts fine when cool but refuses to start after running and heating up. This condition occurs when fuel in the lines or carburetor bowl vaporizes due to heat, creating air pockets that prevent proper fuel flow. Vapor lock is more common with older fuel systems and during hot weather.

Idle and Low-Speed Issues

Rough idle diagnosis involves observing how smoothly the engine runs at idle speed. A carburetor-related rough idle typically varies with throttle adjustments and may improve when the engine is revved slightly. Check if the roughness occurs immediately upon startup or develops as the engine warms up, as this can indicate different carburetor problems.

Stalling at traffic lights or during low-speed operation often indicates an idle mixture that’s too lean or an idle speed that’s set too low. This problem may be intermittent at first but typically worsens over time as carburetor components wear or adjustments drift.

Engine surging at idle appears as rhythmic increases and decreases in engine speed without throttle input. This can result from air leaks in the carburetor mounting, damaged gaskets, or incorrect idle mixture adjustments. The surging may be more pronounced when accessories like air conditioning or headlights are turned on.

Acceleration and High-Speed Problems

Hesitation during acceleration manifests as a stumble or lag when you press the accelerator, particularly during rapid acceleration. This often indicates problems with the accelerator pump (which provides extra fuel during acceleration) or partially clogged main jets that can’t deliver enough fuel under load.

Power loss under load becomes apparent when the engine runs acceptably at idle and light throttle but lacks power when climbing hills or carrying heavy loads. This typically indicates lean fuel mixture problems or restricted fuel flow through the carburetor’s main metering circuits.

Backfiring through the carburetor appears as popping sounds coming from the air cleaner rather than the exhaust. This dangerous condition indicates a lean fuel mixture or incorrect timing and can potentially cause fires in the air cleaner assembly. Stop the engine immediately if carburetor backfiring occurs.

Fuel Economy Changes

Sudden increase in fuel consumption without corresponding performance improvements often indicates rich mixture conditions. Monitor your fuel economy over several fill-ups to establish patterns, as carburetor problems typically cause consistent changes rather than day-to-day variations.

Rich versus lean mixture symptoms present differently but both affect fuel economy. Rich mixtures waste fuel and produce black exhaust smoke, while lean mixtures may initially improve fuel economy but cause power loss and potential engine damage from overheating.

Seasonal performance variations can indicate carburetor problems that worsen under specific conditions. Problems that appear only in cold weather might involve choke system issues, while hot weather problems could indicate vapor lock or heat-related fuel delivery issues.

Simple Diagnostic Tests for Carburetor Problems

Visual Inspection Procedures

Safe fuel system inspection begins with ensuring the engine is cool and the ignition is off. Remove the key to prevent accidental starting, and work in a well-ventilated area away from potential ignition sources. Keep a fire extinguisher nearby and avoid smoking or creating sparks.

Fuel bowl sight glass observation (if equipped) allows you to check fuel level and quality without removing components. The fuel should be at the proper level indicated by markings, appear clean and clear, and not contain visible water or debris. Cloudy fuel or sediment indicates contamination problems.

Linkage and adjustment visual checks involve inspecting throttle and choke linkages for proper operation. Manually operate these controls (with the engine off) to ensure smooth movement without binding or excessive play. Check that return springs pull the linkages back to their rest positions.

Look for obvious damage like bent linkages, missing springs, or loose connections that could affect carburetor operation. Take photos before disassembly to help with reassembly if needed.

Basic Function Tests

Throttle response testing can be performed safely with the engine running and proper safety precautions in place. Have someone rev the engine while you observe the throttle linkage operation. The response should be immediate and smooth, without hesitation or hanging up at any position.

Choke operation verification involves checking both manual and automatic choke systems. For manual chokes, ensure the choke plate closes completely when the choke is applied and opens fully when released. Automatic chokes should close when the engine is cold and gradually open as the engine warms up.

Float level observation (where accessible) requires removing the air cleaner or fuel bowl sight plug. The fuel level should remain constant during operation and not overflow when the engine is turned off. Inconsistent fuel levels indicate float or needle valve problems.

Safety Equipment Required: Always wear safety glasses when working around fuel systems, have adequate lighting to see clearly, and ensure someone else is present when running engines for testing purposes.

Fuel Quality Assessment

Signs of contaminated fuel include cloudy appearance, separation into layers, sediment in the bottom of containers, or unusual odors. Fresh gasoline should be clear and have a characteristic petroleum smell, not sour or varnish-like odors that indicate degradation.

Water in fuel identification appears as a clear separation layer at the bottom of fuel containers or as cloudy, milky-appearing fuel. Water contamination is particularly common with ethanol-blended fuels and can cause severe carburetor problems including corrosion and ice formation.

Age-related fuel degradation becomes apparent through color changes (fuel darkening), gum formation, or varnish-like residues. Fuel older than three months can begin causing carburetor problems, while fuel over six months old should generally be replaced rather than used.

Test fuel quality by draining a small sample into a clear container and examining it in good light. Fresh fuel should be clear, while contaminated or old fuel will show visible signs of deterioration.

When to Clean vs Replace vs Seek Professional Help

DIY Cleaning Candidates

Minor fuel contamination that hasn’t caused permanent damage often responds well to carburetor cleaning. If the engine runs but has performance issues, and you can see debris or gum deposits in accessible areas, cleaning may solve the problem. Simple single-barrel carburetors are the best candidates for DIY cleaning.

Seasonal storage issues like gummed fuel or minor corrosion typically respond to thorough cleaning and fresh fuel. If the equipment ran well before storage and problems appeared after sitting unused, cleaning is often successful.

Basic adjustment needs for idle speed and mixture screws are within DIY capabilities for mechanically inclined owners. However, these adjustments require patience and careful observation of engine behavior during the process.

Required tools and skills include basic hand tools, carburetor cleaner, compressed air, and the ability to follow service manual procedures carefully. You’ll also need a clean workspace and containers for organizing small parts during disassembly.

Replacement Indicators

Severe internal damage like cracked castings, stripped threads, or extensively corroded components typically require carburetor replacement. Evaluate whether repair costs exceed replacement costs, especially for mass-produced small engine carburetors.

Cost-effectiveness analysis should include your time investment, special tools required, and the likelihood of successful repair. Professional carburetor rebuilding may cost more than replacement on smaller engines but could be worthwhile for valuable or rare applications.

Availability of rebuild kits versus new units varies by application. Popular small engines often have inexpensive replacement carburetors available, while classic car applications may require rebuilding due to parts availability or cost considerations.

Professional Service Requirements

Complex multi-barrel carburetors with progressive linkages, vacuum controls, or electronic components require specialized knowledge and tools that exceed typical DIY capabilities. The adjustment procedures alone can be complex enough to warrant professional service.

Integrated electronic components like feedback carburetors or emissions control systems require diagnostic equipment and training that most DIY mechanics don’t possess. Incorrect adjustments can cause drivability problems or emissions compliance issues.

Engine timing relationship issues that affect carburetor performance often require professional diagnosis to determine whether the carburetor itself is faulty or if other engine problems are causing carburetor-like symptoms.

Safety considerations beyond DIY scope include fuel system modifications, emissions compliance requirements, and complex electrical systems integration found on some carbureted vehicles.

For specific brand guidance and detailed service procedures, consult our comprehensive collection of service manuals and technical resources for your equipment manufacturer.

Prevention and Maintenance Tips

Fuel Quality Management

Proper fuel storage practices include using fuel stabilizers for equipment that sits unused for more than 30 days, storing fuel in clean, sealed containers away from temperature extremes, and rotating fuel stock to ensure freshness. Never store equipment with fuel older than three months in the tank.

Seasonal fuel additives can prevent many carburetor problems before they start. Fuel stabilizers prevent gum formation during storage, while water-absorbing additives help manage moisture in ethanol-blended fuels. Use only additives recommended by your equipment manufacturer.

Regular fuel system cleaning involves adding fuel system cleaners to prevent deposit buildup, replacing fuel filters according to manufacturer schedules, and occasionally running the equipment at higher RPMs to help clear minor deposits from jets and passages.

Regular Maintenance Schedule

Air filter replacement importance cannot be overstated for carburetor health. Dirty air filters force carburetors to run rich, while damaged filters allow dirt into the carburetor that can cause permanent damage. Check air filters monthly during heavy use periods and replace as needed.

Periodic adjustment checks should include idle speed, idle mixture (where adjustable), and choke operation verification. These adjustments can drift over time due to vibration, temperature changes, and normal wear. Document original settings before making changes.

Seasonal preparation and storage procedures should include fuel system treatment, carburetor draining (where recommended), and protection from moisture and temperature extremes. Proper storage prevents most carburetor problems from developing during off-seasons.

Early Warning System

Performance monitoring habits involve paying attention to starting characteristics, idle quality, acceleration response, and fuel economy patterns. Changes in any of these areas can indicate developing carburetor problems before they become serious.

Regular visual inspections should check for fuel leaks, corrosion, damaged linkages, and air filter condition. Monthly inspections during use seasons can catch problems early when they’re easier and less expensive to address.

Documentation for pattern recognition includes keeping records of fuel economy, maintenance performed, and any performance changes observed. This information helps identify trends and provides valuable information for professional diagnosis if needed.

Professional Resources and Final Guidance

Key Takeaway Summary

The most important warning signs to remember include difficulty starting (especially when cold), rough idling or stalling, hesitation during acceleration, visible fuel leaks around the carburetor, and sudden changes in fuel economy. Any of these symptoms warrant investigation, but multiple symptoms together almost certainly indicate carburetor problems.

Safety remains the primary consideration in all carburetor diagnostic and repair work. Fuel vapors are extremely dangerous, and proper ventilation, fire prevention, and safe work practices are essential. Never take shortcuts with fuel system safety, and don’t hesitate to seek professional help if you’re uncomfortable with any procedure.

When in doubt, consult professionals rather than risk safety or expensive damage. A professional diagnosis can often save money by identifying the exact problem and preventing unnecessary parts replacement or incorrect repairs.

Professional Consultation Guidance

Information to provide to mechanics includes detailed symptom descriptions, when problems occur, recent maintenance history, fuel quality and age, and any diagnostic steps you’ve already taken. Photos or videos of symptoms can be particularly helpful for professional diagnosis.

Questions to ask service providers should cover their experience with your specific type of carburetor, estimated repair costs versus replacement costs, warranty on work performed, and expected timeline for completion.

Verifying repair quality involves test driving or operating the equipment through its full range of operating conditions, ensuring all original symptoms have been resolved, and confirming that no new problems have been introduced.

Additional Resources

For detailed troubleshooting procedures specific to your equipment, explore our comprehensive brand-specific service manuals covering everything from classic automotive applications to modern small engines. Our technical resources include step-by-step diagnostic procedures, adjustment specifications, and safety guidelines tailored to your specific equipment.

Whether you’re working on a vintage Chevrolet carburetor or troubleshooting a Honda small engine, having the right technical information ensures safe, effective repairs.

Remember that carburetor problems, while sometimes frustrating, are generally predictable and preventable with proper maintenance and attention to early warning signs. By developing good observation habits and understanding your equipment’s normal operating characteristics, you can spot problems early and address them before they leave you stranded.

Disclaimer: This information is provided for educational purposes only. Always follow manufacturer recommendations and safety procedures. If you’re not comfortable performing any diagnostic or repair procedures, consult a qualified technician. Improper fuel system work can result in fire, explosion, or serious injury.