The check engine light just came on, and your car feels sluggish during acceleration. Maybe you’ve noticed a slight roughness at idle, or perhaps your fuel economy has mysteriously dropped. When you finally get the diagnostic codes read, you see something like P0011 or P0014—codes that point to your camshaft actuator. If you’re scratching your head wondering what this component is and why it’s causing problems, you’re not alone. The camshaft actuator is one of those modern automotive marvels that most drivers never think about until something goes wrong.

This sophisticated piece of engineering is actually a critical component in your engine’s Variable Valve Timing (VVT) system, designed to optimize performance, improve fuel efficiency, and reduce emissions. When functioning properly, the camshaft actuator seamlessly adjusts valve timing to match driving conditions, giving you the best of both worlds: smooth idle and low-end torque when you need it, plus peak power at higher RPMs. But when it fails, the effects can range from annoying performance issues to potential engine damage if left unaddressed.

Understanding your camshaft actuator isn’t just about satisfying curiosity—it’s about making informed decisions when facing repair costs that can range from hundreds to over a thousand dollars. In this comprehensive guide, we’ll explore how this ingenious hydraulic device works, what symptoms indicate trouble, and why professional diagnosis is essential for these complex systems. Whether you’re a vehicle owner trying to understand a repair estimate or a technician looking to deepen your VVT system knowledge, this article provides the technical depth and practical guidance you need to navigate camshaft actuator issues with confidence.

What is a Camshaft Actuator?

A camshaft actuator is a sophisticated hydraulic device that adjusts the timing of your camshaft relative to the crankshaft, allowing your engine to optimize valve timing for different operating conditions. Think of it as a precision timing adjuster that uses engine oil pressure to rotate the camshaft forward or backward by several degrees, changing when the intake and exhaust valves open and close. This technology, also known as a camshaft phaser or VVT actuator, represents one of the most significant advances in internal combustion engine efficiency in recent decades.

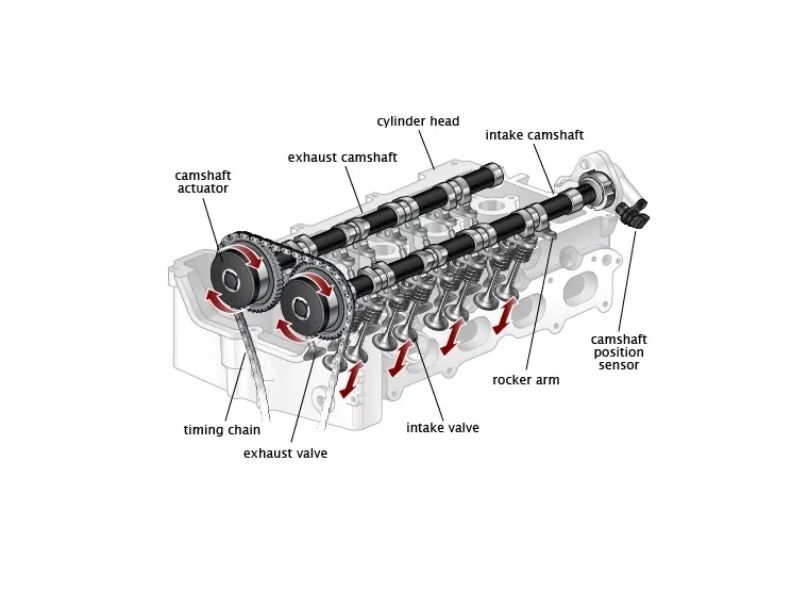

The camshaft actuator consists of a complex assembly of precisely machined components housed within what looks like a modified timing chain sprocket. The heart of the system is a rotor and stator arrangement, where the inner rotor connects to the camshaft while the outer housing connects to the timing chain. Between these components are carefully designed oil chambers that, when filled with pressurized engine oil, cause the rotor to move relative to the housing, effectively advancing or retarding camshaft timing.

Physically, you’ll find the camshaft actuator integrated with the timing sprocket at the front of the camshaft, typically hidden behind the timing cover. This location is both strategic and challenging—strategic because it’s directly connected to the timing drive system, but challenging because accessing it requires significant timing system disassembly. The actuator is controlled by an electronically operated oil control valve (often called a VVT solenoid) that directs pressurized engine oil into the appropriate chambers based on commands from the Engine Control Unit (ECU).

From an engineering perspective, the camshaft actuator represents a remarkable fusion of hydraulic and electronic technologies. The system must operate with millisecond precision, responding to constantly changing engine conditions while maintaining the mechanical integrity essential for timing system operation. Modern engines may have multiple actuators—one for each camshaft in dual overhead cam (DOHC) engines, or separate intake and exhaust actuators in more sophisticated systems. Each actuator must work in perfect harmony with the others while responding to complex engine management algorithms that consider factors like engine load, RPM, temperature, and emission requirements.

The integration of camshaft actuators into modern engines reflects the automotive industry’s response to increasingly stringent emission regulations and consumer demands for both performance and fuel efficiency. Unlike the fixed timing of traditional engines that represented a compromise between low-end torque and high-RPM power, variable valve timing allows engineers to optimize performance across the entire operating range while meeting strict emission standards that would be impossible with conventional timing systems.

How Camshaft Actuators Work

The operation of a camshaft actuator relies on precisely controlled hydraulic pressure to create rotational movement between the camshaft and its timing sprocket. Engine oil serves as the hydraulic fluid, with the system using the existing oil pump and pressure to operate the actuator chambers. When the ECU determines that timing adjustment is needed, it sends a signal to the VVT solenoid valve, which directs oil flow to specific chambers within the actuator assembly.

The mechanical principle is elegantly simple yet precisely executed. The actuator contains multiple oil chambers separated by vanes or lobes on the inner rotor. When oil pressure is applied to one side of these chambers, it forces the rotor to rotate relative to the outer housing, either advancing or retarding the camshaft timing. Advancing the timing means the valves open earlier in the cycle, while retarding means they open later, each providing different performance characteristics depending on engine operating conditions.

Electronic control integration makes this hydraulic system remarkably sophisticated. The ECU continuously monitors engine parameters including RPM, load, throttle position, coolant temperature, and intake air temperature to determine optimal timing for current conditions. The system receives feedback through the camshaft position sensor, which tells the ECU exactly where the camshaft is positioned relative to the crankshaft, allowing for precise closed-loop control of the timing adjustment.

The oil control solenoid acts as the critical interface between the electronic and hydraulic systems. This electronically controlled valve can direct oil flow in either direction or block flow entirely, allowing the actuator to advance timing, retard timing, or hold its current position. The solenoid operates using pulse-width modulation (PWM), where the ECU varies the electrical signal to achieve precise control over oil flow rates and, consequently, the speed and extent of timing changes.

Performance optimization through variable timing provides benefits that would be impossible with fixed timing systems. At low RPMs and light loads, the system typically advances intake timing to improve cylinder filling and provide better low-end torque. During high-RPM operation, the timing may be retarded to optimize power output and prevent engine knock. For emission control, the system can adjust valve overlap—the period when both intake and exhaust valves are open—to control combustion characteristics and reduce harmful emissions.

The relationship between oil pressure and actuator response creates some interesting operational characteristics. Proper oil pressure is absolutely critical for actuator function, which is why oil quality and maintenance intervals become so important in VVT-equipped engines. Contaminated oil, low oil levels, or degraded oil can significantly affect actuator response time and accuracy, leading to performance problems and eventually component failure. This hydraulic dependency also explains why many VVT problems are actually oil system problems in disguise.

Variable Valve Timing System Benefits

Variable valve timing technology delivers significant advantages across multiple aspects of engine performance, making it a cornerstone of modern engine design. The primary benefit is performance optimization across the entire RPM range, eliminating the traditional compromise between low-end torque and high-RPM power. Fixed timing systems must choose a timing specification that balances these conflicting requirements, while VVT systems can optimize timing for each specific operating condition.

Fuel efficiency improvements represent one of the most significant consumer benefits of VVT technology. By optimizing valve timing for current engine conditions, the system can improve combustion efficiency, reduce pumping losses, and enhance cylinder filling characteristics. During light-load cruising conditions, the system can adjust timing to minimize fuel consumption, while still providing full performance capability when needed. These efficiency gains typically translate to 5-10% improvement in fuel economy compared to equivalent fixed-timing engines.

Emission control benefits make VVT technology essential for meeting modern environmental regulations. The system can precisely control valve overlap to manage exhaust gas recirculation (EGR) internally, reducing nitrogen oxide (NOx) formation without external EGR systems. By optimizing combustion timing and characteristics, VVT systems also reduce hydrocarbon and carbon monoxide emissions while maintaining performance. Some advanced systems can eliminate the need for traditional EGR valves entirely by using variable exhaust timing to achieve the same emission control objectives.

Enhanced engine responsiveness and refinement represent additional VVT advantages that drivers notice immediately. The system can provide crisp throttle response across the RPM range while maintaining smooth idle characteristics that would be difficult to achieve with aggressive fixed timing. Cold start performance also benefits significantly, as the system can optimize timing for faster warm-up while reducing emission spikes during the critical first few minutes of operation.

Torque characteristics become much more flexible with VVT technology, allowing engines to produce substantial low-end torque without sacrificing high-RPM capability. This flexibility enables engine designers to use smaller displacement engines with turbocharging or supercharging while maintaining excellent drivability. The broader torque curve also reduces the need for frequent gear changes in manual transmissions and allows automatic transmissions to operate more efficiently.

Engine longevity benefits from VVT systems stem from optimized operating conditions and reduced mechanical stress. By preventing engine knock through precise timing control, the system protects pistons, rings, and bearings from detonation damage. The ability to optimize valve timing also reduces stress on valve train components while ensuring proper cylinder filling and exhaust evacuation across all operating conditions. Proper engine management becomes even more critical with these sophisticated systems, as they depend on precise oil pressure and temperature control for optimal operation.

Common Symptoms of Camshaft Actuator Failure

The check engine light represents the most common and reliable indicator of camshaft actuator problems. Modern engine management systems continuously monitor camshaft position and timing correlation, triggering diagnostic trouble codes when the actuator fails to respond properly or when timing falls outside acceptable parameters. Common codes include P0011 (intake timing over-advanced), P0014 (exhaust timing over-advanced), P0016 (crankshaft/camshaft correlation), and P0020-P0024 (various timing control circuit malfunctions). These codes provide valuable diagnostic information, but professional interpretation is essential for accurate diagnosis and repair planning.

Engine performance degradation often manifests as reduced power output, sluggish acceleration, and poor throttle response. When the actuator fails to adjust timing properly, the engine loses the performance optimization that VVT systems provide, effectively reverting to fixed timing operation or worse. Drivers typically notice this as a general feeling that the engine isn’t running as smoothly or powerfully as before, particularly during acceleration or when climbing hills. The symptoms may be subtle at first but tend to worsen as the actuator problem progresses.

Rough idle conditions frequently develop when camshaft actuators begin failing, as the system loses its ability to optimize timing for smooth low-RPM operation. The engine may exhibit irregular RPM fluctuations, vibration, or instability when idling, particularly when cold or when accessories like air conditioning place additional load on the engine. This symptom can be particularly frustrating because it affects daily driving comfort and may worsen over time as the actuator response becomes more erratic.

Unusual engine noises during startup often indicate actuator or related timing system problems. A rattling or knocking sound during cold starts may suggest that the actuator isn’t properly controlling timing, allowing timing chain slack or irregular valve operation. These noises typically occur because the hydraulic system needs time to build proper oil pressure, and failing actuators may not respond quickly enough to establish correct timing during startup. The noises usually subside as the engine warms up and oil pressure stabilizes, but they indicate developing problems that require attention.

Hard starting or extended cranking can result from improper valve timing caused by actuator failure. When the actuator is stuck in an incorrect position, valve timing may be so far off that the engine struggles to achieve proper combustion during startup. This symptom is particularly noticeable during cold starts when precise timing is crucial for ignition. In severe cases, the engine may refuse to start at all, requiring professional diagnosis to determine whether the problem is actuator-related or involves other timing system components.

Fuel economy degradation represents a subtle but significant symptom of actuator problems. When the VVT system can’t optimize timing for efficient operation, fuel consumption typically increases noticeably, particularly during highway driving where the system would normally provide maximum efficiency. Drivers may notice they’re filling up more frequently or that their usual driving routes require more fuel than expected.

Transmission-related symptoms can occur because engine performance irregularities affect transmission operation. Some drivers report hard shifting, delayed shifts, or unusual shift quality when camshaft actuators begin failing. This happens because the transmission control module relies on engine performance data to time shifts properly, and irregular engine operation from VVT problems can confuse the transmission’s adaptive learning systems. These symptoms highlight the interconnected nature of modern automotive systems and why proper diagnosis is essential for accurate problem identification.

Causes of Camshaft Actuator Failure

Oil quality problems represent the leading cause of camshaft actuator failure in most vehicles. The hydraulic nature of VVT systems makes them extremely sensitive to oil condition, with contaminated, degraded, or incorrect oil causing rapid actuator deterioration. Dirty oil can clog the small passages within the actuator, while oil that’s lost its viscosity properties may not provide sufficient hydraulic pressure for proper operation. Extended oil change intervals, particularly beyond manufacturer recommendations, create the perfect conditions for actuator failure as oil additives break down and contaminants accumulate.

Low oil pressure conditions can prevent actuators from functioning properly, leading to timing errors and eventual component failure. This can result from a worn oil pump, clogged oil filter, or insufficient oil level, but can also occur from internal engine wear that reduces oil pressure system efficiency. When oil pressure drops below the threshold needed for actuator operation, the system may default to a limp-home mode or fail entirely. Some engines are particularly sensitive to oil pressure variations, making regular oil system maintenance critical for VVT system longevity.

Mechanical wear within the actuator assembly eventually leads to failure even with proper maintenance. The precision hydraulic seals, vanes, and chambers within the actuator are subject to constant pressure cycles and wear from oil-borne contaminants. High-mileage vehicles naturally experience increased actuator wear, particularly if they’ve experienced periods of poor oil maintenance or have been operated under severe conditions. Manufacturing tolerances in some actuator designs make them more prone to wear than others, with certain engine models having known actuator longevity issues.

Timing chain stretch or tensioner problems can cause actuator failure through secondary effects. When timing chains stretch beyond acceptable limits, the actuator must work harder to maintain proper timing correlation, potentially exceeding its designed operating range. This can cause internal damage to the actuator mechanism or prevent it from achieving the full range of timing adjustment needed for proper operation. Timing system problems and actuator failures often occur together, making comprehensive diagnosis essential for determining the root cause and preventing repeat failures.

Solenoid valve failures represent another common failure mode in VVT systems. The oil control solenoid that directs hydraulic flow to the actuator contains precision electronic and hydraulic components that can fail due to electrical problems, contamination, or wear. Common solenoid problems include stuck valves, electrical circuit failures, and internal contamination that prevents proper oil flow control. These failures can mimic actuator problems, making proper diagnosis crucial for accurate repair.

Coolant system problems can contribute to actuator failure through overheating or temperature-related issues. Excessive engine temperatures can break down oil more rapidly and affect the precision hydraulic components within the actuator. Poor cooling system maintenance can lead to oil degradation and accelerated component wear. Some engines also integrate coolant passages near VVT components, making coolant leaks a potential source of actuator contamination.

Aftermarket component quality and installation issues can create premature actuator failures. Non-OEM actuators may not meet the precise specifications required for proper VVT system operation, while improper installation can damage sensitive hydraulic components. Using incorrect oil filters, aftermarket oil additives, or wrong oil viscosity grades can also negatively impact actuator operation and lead to premature failure. Professional installation with OEM-quality components becomes essential for reliable long-term operation.

Diagnostic Procedures

Professional-grade diagnostic equipment is essential for accurate camshaft actuator diagnosis, as these systems require more sophisticated testing than basic OBD-II code reading. Advanced scan tools capable of bi-directional control, live data monitoring, and actuator command testing are necessary to properly evaluate VVT system operation. Consumer-level code readers may identify that VVT codes are present, but they cannot perform the functional testing required to differentiate between actuator problems, solenoid failures, oil pressure issues, or timing system mechanical problems.

Initial diagnosis begins with comprehensive code analysis and live data monitoring to understand the nature and timing of the failure. Professional technicians examine not just the presence of diagnostic codes, but their relationship to operating conditions, frequency of occurrence, and correlation with other system codes. Live data analysis reveals whether the actuator is responding to commands, how quickly it responds, and whether it can achieve the full range of timing adjustment. This information is crucial for determining whether the problem is mechanical, hydraulic, or electronic in nature.

Oil system assessment represents a critical diagnostic step that many shops unfortunately skip. Proper diagnosis includes verification of oil level, quality, pressure, and flow characteristics, as hydraulic problems often masquerade as actuator failures. Oil analysis can reveal contamination, additive depletion, or viscosity breakdown that could affect actuator operation. Pressure testing at the actuator supply point confirms whether adequate hydraulic pressure is available for proper operation, while flow testing can identify restrictions or blockages in the oil control circuits.

Electrical testing of the VVT solenoid and related circuits requires specialized knowledge and equipment. Technicians must verify proper voltage supply, ground circuits, and signal control from the ECU while testing the solenoid’s electrical resistance and response characteristics. Oscilloscope analysis can reveal pulse-width modulation patterns and help identify intermittent electrical problems that might not be apparent with basic multimeter testing. The relationship between electrical commands and hydraulic response must be verified to ensure the entire control system is functioning properly.

Mechanical timing system inspection becomes necessary when actuator problems are suspected to have mechanical causes. This includes timing chain tension verification, sprocket condition assessment, and timing correlation measurement using precision timing equipment. Some timing system problems can cause actuator failure, while some actuator failures can cause timing system damage, making comprehensive evaluation essential for proper repair planning. Visual inspection of timing components often reveals evidence of oil contamination, wear patterns, or damage that provides clues about the root cause of actuator problems.

Differential diagnosis techniques help distinguish between actuator failure and related component problems that can produce similar symptoms. Professional technicians systematically test each component in the VVT system, including position sensors, oil control valves, and ECU functions, to isolate the actual failure point. This process prevents unnecessary component replacement and ensures that underlying problems are addressed before installing new parts. The interconnected nature of modern engine systems makes this systematic approach essential for accurate diagnosis and successful repair.

Functional testing using professional diagnostic equipment allows technicians to command actuator operation and verify response in real-time. This testing can reveal sluggish response, limited range of motion, or complete failure to respond to commands. Temperature-dependent testing may be necessary, as some actuator problems only manifest under specific operating conditions. Professional diagnostic procedures require not just the right equipment, but the training and experience to interpret results accurately and develop effective repair strategies.

Repair and Replacement Procedures

Camshaft actuator replacement requires professional expertise due to the complexity of timing system involvement and the precision required for proper installation. This is not a suitable DIY project for most vehicle owners, as improper timing during reassembly can cause catastrophic engine damage in interference engines. The procedure involves timing system disassembly, precise timing mark documentation, and specialized tools for both removal and installation. Professional technicians possess the knowledge, tools, and experience necessary to perform this complex repair safely and correctly.

Timing system access requires extensive disassembly that goes far beyond simple component replacement. The procedure typically begins with removing the engine timing cover, accessory drive components, and timing belt or chain systems to access the camshaft actuator. Critical timing marks must be documented and verified before any disassembly, as even slight timing errors during reassembly can cause valve-to-piston contact in interference engines. This level of disassembly also provides an opportunity to inspect related timing components that may need service or replacement.

Oil system service becomes an integral part of actuator replacement, as contaminated oil likely contributed to the original failure. Professional service includes complete oil and filter replacement using the correct viscosity and quality specifications for VVT system operation. Some technicians also perform oil system flushing to remove contaminants that could affect the new actuator, particularly in high-mileage engines or those with evidence of poor maintenance. Oil pressure testing before and after actuator installation ensures the hydraulic system can support proper operation.

Component installation requires precise attention to timing marks, torque specifications, and assembly procedures. New actuators must be installed with proper orientation and timing correlation, while related components like timing chains, tensioners, and guides are typically inspected and often replaced during the service. Professional installation includes verification of timing correlation at multiple points during reassembly to ensure proper system operation. OEM-quality components are essential for reliable operation, as aftermarket parts may not meet the precise specifications required for VVT system function.

Related component evaluation often reveals additional service needs that should be addressed during actuator replacement. Timing chains, tensioners, guides, and water pumps are commonly replaced during actuator service, as they share similar service intervals and require the same access procedures. Solenoid valves, oil control valves, and camshaft position sensors may also need replacement if they’ve been damaged by oil contamination or if they’re approaching their service life. Coordinating these services during actuator replacement minimizes labor costs and ensures comprehensive system reliability.

Post-installation procedures include timing verification, oil pressure testing, and ECU relearning processes. Professional service ensures that timing correlation is correct, oil pressure is adequate for actuator operation, and that the ECU recognizes the new components and adjusts its control parameters accordingly. Some vehicles require specific relearning procedures or calibration updates after VVT system service. Initial startup and road testing verify proper operation under various operating conditions before returning the vehicle to service.

Quality control measures distinguish professional service from incomplete repairs that may lead to repeat failures. Proper service includes documentation of timing marks, torque specifications, and test results that verify system operation. Follow-up monitoring and customer education help ensure long-term reliability and proper maintenance practices that will protect the new components. Professional timing system service represents an investment in both immediate problem resolution and long-term engine reliability.

Cost Analysis and Repair Economics

Camshaft actuator replacement represents a significant investment, with total costs typically ranging from $944 to $1,239 for professional service, though complex engines or multiple actuator replacement can push costs considerably higher. Parts costs alone range from $150 to $400 for quality OEM actuators, but labor represents the majority of the expense due to timing system complexity. Professional shops typically charge 6-12 hours of labor for actuator replacement, reflecting the extensive disassembly required and the precision needed for proper timing system reassembly.

Vehicle complexity significantly influences repair costs, with single overhead cam (SOHC) engines typically costing less to service than dual overhead cam (DOHC) engines with multiple actuators. Luxury vehicles and high-performance engines command premium pricing due to their sophisticated designs, specialized tools requirements, and higher parts costs. Some engine configurations require partial engine removal or extensive component disassembly that can increase labor time substantially. Interference engines also require extra care and precision during timing procedures, potentially increasing service time and costs.

Regional cost variations reflect differences in labor rates, with metropolitan areas typically charging premium rates compared to rural locations. Dealership service departments usually charge more than independent shops, but they offer specialized knowledge, genuine OEM parts, and warranty coverage that may justify the premium for complex VVT system repairs. Shop efficiency and specialization can also affect costs, as facilities experienced with VVT systems may complete repairs more efficiently than shops unfamiliar with these complex systems.

Economic timing strategies can provide significant cost savings when actuator replacement is coordinated with related maintenance services. Combining actuator replacement with timing belt or chain service eliminates duplicate labor charges, as both services require similar disassembly procedures. Water pump replacement, timing system component service, and related seal replacement often make economic sense when performed during actuator service, even if these components haven’t failed yet. This preventive approach minimizes future labor costs while ensuring comprehensive system reliability.

Multiple actuator replacement in engines with several VVT actuators presents both challenges and opportunities. While replacing all actuators simultaneously increases immediate costs, it eliminates the likelihood of repeat timing system disassembly for individual actuator failures. Some shops offer package pricing for multiple actuator replacement that provides better value than individual services. The decision should consider vehicle age, mileage, and maintenance history to determine the most cost-effective approach.

Risk assessment must consider the consequences of delaying actuator repair or attempting less expensive alternatives. Continued operation with failed actuators can cause timing chain damage, engine performance degradation, and potential emission system problems that increase overall repair costs. Aftermarket or remanufactured actuators may offer initial cost savings but could lead to premature failure and repeat repair costs. Professional diagnosis and quality repair represent the most cost-effective long-term approach for most vehicle owners.

Warranty considerations provide additional value through professional service channels. Reputable shops offer warranty coverage on parts and labor, providing protection against premature failure or installation defects. Professional service also maintains manufacturer warranty coverage and service history documentation that supports vehicle resale value. Understanding the economic factors involved in engine repairs helps vehicle owners make informed decisions about repair timing and service quality.

Prevention and Maintenance

Oil system maintenance represents the single most important factor in camshaft actuator longevity and VVT system reliability. Manufacturer-specified oil change intervals must be followed religiously, and many experts recommend shorter intervals for VVT-equipped engines due to their sensitivity to oil quality. High-quality oil with the correct viscosity and additive package is essential, as VVT systems depend on precise oil pressure and flow characteristics that can be compromised by incorrect or degraded lubricants. Synthetic oils often provide better VVT system protection due to their superior thermal stability and resistance to breakdown.

Oil filter quality and replacement intervals become even more critical in VVT systems due to their sensitivity to contamination. High-efficiency oil filters help protect the small passages and precise components within actuators and control valves. Some manufacturers specify particular filter designs or efficiency ratings for VVT-equipped engines, making it important to use filters that meet these specifications rather than generic alternatives. Regular filter replacement prevents contamination buildup that could affect actuator operation or cause premature component failure.

Operating practices significantly influence VVT system longevity, particularly during startup and warm-up periods. Allowing proper engine warm-up before aggressive driving helps ensure adequate oil pressure and temperature for optimal actuator operation. Avoiding frequent short trips that don’t allow complete engine warm-up reduces the thermal stress on VVT components while ensuring proper oil circulation throughout the system. Highway driving that allows the engine to reach normal operating temperature helps maintain oil quality and system health.

Professional inspection during routine maintenance provides early detection of developing VVT system problems. Experienced technicians can identify subtle performance changes, unusual noises, or diagnostic code patterns that indicate developing actuator problems before complete failure occurs. Regular diagnostic scans can reveal intermittent codes or performance parameters that suggest maintenance needs or developing component wear. This proactive approach allows for planned repairs rather than unexpected failures that could cause additional engine damage.

Cooling system maintenance directly affects VVT system reliability through its impact on oil temperature and engine thermal management. Proper coolant levels, quality, and thermostat operation help maintain optimal oil temperatures that protect VVT components from thermal stress. Regular cooling system service prevents overheating conditions that can rapidly degrade oil quality and damage precision hydraulic components. Some engines integrate coolant passages near VVT components, making cooling system maintenance even more critical for actuator longevity.

Fuel quality and injection system maintenance indirectly affect VVT system health through their impact on combustion quality and oil contamination. Poor fuel quality or injection system problems can cause combustion issues that contaminate engine oil with fuel dilution or combustion byproducts that affect VVT operation. Regular fuel system maintenance and quality fuel help maintain optimal combustion characteristics that protect both the engine and VVT system components.

Preventive replacement strategies based on mileage and maintenance history can prevent unexpected failures and reduce long-term costs. Some technicians recommend proactive actuator replacement during major timing system service, particularly in high-mileage vehicles or those with histories of poor maintenance. This approach prevents the inconvenience and expense of unexpected failure while taking advantage of timing system access for other services. Understanding your vehicle’s maintenance needs and planning accordingly helps ensure reliable VVT system operation throughout the vehicle’s lifetime.

When to Seek Professional Help

The complexity of VVT systems and their integration with timing components makes professional diagnosis and repair essential for most camshaft actuator problems. These systems require specialized diagnostic equipment, extensive technical knowledge, and precision timing procedures that exceed the capabilities of most DIY mechanics. The risk of catastrophic engine damage from timing errors during repair makes professional service a prudent investment for protecting your engine and avoiding costly mistakes that could result in complete engine rebuilds.

Diagnostic accuracy represents a critical advantage of professional service, as VVT problems can mimic other engine issues or be caused by related component failures. Professional technicians possess the training and equipment necessary to differentiate between actuator problems, oil pressure issues, timing system mechanical problems, and electronic control failures. This diagnostic accuracy prevents unnecessary component replacement and ensures that underlying problems are addressed before installing new parts. Misdiagnosis can lead to repeat failures and increased repair costs that exceed the value of professional service.

Specialized tool requirements for VVT system service typically exceed DIY capabilities and justify professional service costs. Timing system service requires specialized holding tools, timing equipment, and precision measuring instruments that represent significant investments for single-use applications. Professional shops maintain comprehensive tool inventories and have access to manufacturer-specific equipment that ensures proper repair procedures and optimal results. The cost of acquiring necessary tools often exceeds the price of professional service for individual repairs.

Timing system precision and the consequences of errors make professional expertise essential for safe and reliable repair. Even small timing errors can cause valve-to-piston contact in interference engines, resulting in complete engine rebuilds costing thousands of dollars more than the original repair. Professional technicians understand the critical timing relationships and possess the experience necessary to avoid these catastrophic mistakes. The risk-to-cost ratio strongly favors professional service for timing-related repairs in modern engines.

Warranty protection and service documentation provide additional value through professional service channels. Reputable shops offer comprehensive warranty coverage on parts and labor, providing protection against premature failure or installation defects. Professional service maintains manufacturer warranty coverage and creates service documentation that supports warranty claims and vehicle resale value. This protection and documentation often justify the cost premium for professional service over alternative repair approaches.

Multiple system integration in modern vehicles requires comprehensive knowledge that exceeds single-system expertise. VVT problems can affect engine management, transmission operation, and emission control systems in ways that require broad technical knowledge for proper diagnosis and repair. Professional technicians understand these system interactions and can address related problems that might not be apparent during focused component replacement. This comprehensive approach ensures reliable operation and prevents related problems that could cause repeat service needs.

When diagnostic codes indicate VVT system problems, professional consultation becomes essential for accurate problem identification and cost-effective repair planning. The complexity of these systems and their critical role in engine operation make professional service the recommended approach for ensuring reliable, long-term repair results. For vehicle-specific guidance and detailed repair procedures, technical manual resources provide manufacturer-specific information that supports professional diagnosis and repair procedures.

Conclusion

The camshaft actuator represents one of the most sophisticated and critical components in modern engine design, serving as the key enabler for Variable Valve Timing systems that optimize performance, efficiency, and emissions across all operating conditions. Understanding this component’s role helps you appreciate why proper maintenance is so crucial and why professional service is essential when problems develop. These precision hydraulic devices operate in demanding conditions with tight tolerances, making them sensitive to oil quality, maintenance intervals, and operating practices that directly impact their longevity and reliability.

When camshaft actuator problems occur, prompt professional diagnosis and repair protect your engine from secondary damage while restoring the performance and efficiency benefits that VVT systems provide. The symptoms may seem subtle at first—a check engine light, slight roughness, or reduced fuel economy—but ignoring these warning signs can lead to more extensive timing system problems and costly repairs. Professional technicians possess the specialized knowledge, diagnostic equipment, and tools necessary to accurately diagnose VVT system problems and perform reliable repairs that address root causes rather than just symptoms.

The investment in quality professional service for camshaft actuator problems pays dividends in long-term reliability, maintained vehicle value, and continued optimal engine performance. While the costs may seem significant, they pale in comparison to the potential consequences of timing system damage or the repeated repairs that can result from inadequate service. Coordinating actuator replacement with related timing system maintenance provides the best value while ensuring comprehensive system reliability for years to come.

Prevention through proper maintenance remains the most cost-effective approach to VVT system care, with oil quality and change intervals serving as the foundation for actuator longevity. Regular professional inspections can identify developing problems before they cause complete failure, allowing for planned repairs rather than emergency service. Understanding your vehicle’s VVT system needs and maintaining them properly ensures that you continue to enjoy the performance, efficiency, and reliability benefits that these sophisticated systems provide.

For comprehensive vehicle-specific information about VVT systems and camshaft actuator service procedures, consult the detailed manual resources available through Repairs Advisor, which provide manufacturer-specific technical guidance for accurate diagnosis and professional repair. When facing VVT system problems, remember that professional consultation offers the best path to reliable, cost-effective solutions that protect your engine investment and maintain optimal vehicle performance. The camshaft actuator may be a small component, but its role in modern engine management makes it worthy of the respect, maintenance, and professional service it requires for long-term reliability and performance.