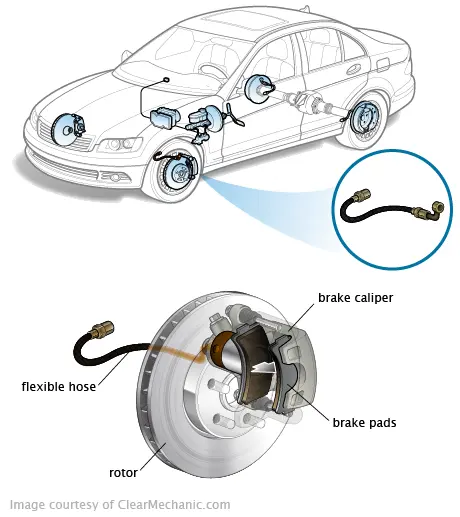

Every time you press your brake pedal, you’re trusting a complex hydraulic system to stop your vehicle safely. While most drivers focus on brake pads and rotors, brake flexible hoses play an equally critical role in your vehicle’s stopping power. These seemingly simple components are the vital links that carry pressurized brake fluid from your vehicle’s rigid brake lines to the moving components at each wheel.

According to the National Highway Traffic Safety Administration, brake-related failures contribute to approximately 22% of traffic accidents, with hydraulic system failures being a significant factor. Understanding brake flexible hoses and recognizing early warning signs of failure can literally save lives and prevent catastrophic brake system failures.

Unlike the rigid brake lines that run along your vehicle’s frame, flexible brake hoses must accommodate the constant movement of your suspension system while maintaining perfect hydraulic seal integrity. These hoses endure extreme conditions including high hydraulic pressure (up to 2,000 PSI), temperature variations from -40°F to 300°F, road salt, debris impact, and constant flexing motion. This demanding environment makes brake hoses one of the most stressed components in your brake system.

In this comprehensive guide, we’ll explore everything you need to know about brake flexible hoses, from their construction and function to inspection procedures and replacement techniques. Whether you’re a DIY enthusiast, professional mechanic, or fleet manager, this information will help you maintain safe and reliable braking performance.

Important Safety Disclaimer: This information is provided for educational reference only. Brake system work involves critical safety components. Always implement procedures at your own risk and responsibility. When in doubt, consult a qualified professional technician.

The Anatomy and Function of Brake Flexible Hoses

Brake flexible hoses are engineered marvels designed to withstand extreme conditions while maintaining perfect hydraulic integrity. Understanding their construction helps you recognize potential failure points and appreciate why regular inspection is crucial.

Construction and Materials

Modern brake flexible hoses feature a sophisticated multi-layer construction designed for durability and performance:

Inner Tube Layer: The innermost layer consists of synthetic rubber compound specifically formulated for compatibility with all DOT-approved brake fluids (DOT 3, DOT 4, and DOT 5.1). This layer must resist chemical degradation, temperature extremes, and maintain flexibility throughout the brake fluid temperature range.

Reinforcement Layer: Surrounding the inner tube is a braided reinforcement layer, typically made from high-tensile steel wire or synthetic textile fibers. This layer provides the structural strength needed to contain hydraulic pressures up to 2,000 PSI while allowing flexibility for suspension movement. The reinforcement layer is critical for preventing hose expansion under pressure, which would result in a spongy brake pedal feel.

Outer Cover: The external layer protects against environmental damage including road salt, oils, UV radiation, and physical abrasion. This layer typically consists of weather-resistant synthetic rubber with additives for ozone and heat resistance.

End Fittings: Brake hoses terminate with precisely machined steel fittings that create leak-proof connections to brake lines and components. These fittings use either banjo bolt connections or threaded AN (Army-Navy) style fittings, depending on the application.

Primary Functions

Brake flexible hoses serve several critical functions in your vehicle’s hydraulic brake system:

Hydraulic Pressure Transmission: The primary function is transmitting brake fluid pressure from the master cylinder through the brake lines to the brake calipers and wheel cylinders. Any pressure loss in the hoses directly reduces braking effectiveness.

Suspension Movement Accommodation: Unlike rigid brake lines, flexible hoses must accommodate the constant movement of suspension components during steering, braking, and road surface variations. A typical front brake hose may flex hundreds of times during a single trip as the wheels turn and the suspension moves.

Vibration Dampening: Brake hoses help isolate brake components from engine and road vibrations, preventing premature wear of brake system seals and reducing brake noise.

System Pressure Maintenance: Quality brake hoses maintain consistent internal diameter under pressure, ensuring proper brake fluid flow and pressure distribution to all brake components.

Location in Brake System

Brake flexible hoses are strategically positioned at points where the brake system transitions from fixed components to moving parts:

Front Brake Connections: Front hoses typically connect the chassis-mounted brake line to the brake caliper, which moves with the steering knuckle during steering input and suspension travel.

Rear Brake Connections: Rear hoses connect the chassis brake line to the rear axle or independent rear suspension components. On vehicles with rear drum brakes, hoses connect to the wheel cylinders.

ABS System Integration: Modern vehicles with Anti-lock Braking Systems (ABS) may have additional flexible hoses connecting the ABS modulator to various brake components, requiring specialized attention during inspection and service.

Different Types of Brake Flexible Hoses

Understanding the various types of brake flexible hoses helps ensure you select the correct replacement components and understand their performance characteristics.

Classification by Application

Front Brake Hoses: Front brake hoses typically operate under higher stress due to greater steering-induced flexing and higher brake forces. They’re usually shorter but must accommodate significant angular movement during steering. Front brake hoses often fail first due to their demanding operating environment.

Rear Brake Hoses: Rear brake hoses generally experience less angular movement but may be longer to accommodate rear suspension geometry. On solid axle vehicles, rear hoses must accommodate significant vertical movement during suspension travel.

ABS-Specific Hoses: Vehicles equipped with ABS may have additional flexible hoses connecting the ABS hydraulic unit to the master cylinder or individual brake circuits. These hoses must meet additional specifications for compatibility with ABS operation and may require special bleeding procedures.

Construction Classifications

Single Layer Reinforcement: Standard construction suitable for most passenger vehicles operating under normal conditions. These hoses meet DOT FMVSS 106 specifications for passenger car applications.

Double Layer Reinforcement: Enhanced construction with dual reinforcement layers for heavy-duty applications, commercial vehicles, or performance applications where higher burst pressure is required.

Stainless Steel Braided Hoses: Premium construction featuring stainless steel braided outer layer for maximum durability and performance. These hoses offer superior resistance to expansion under pressure, resulting in firmer brake pedal feel and improved brake response. They’re commonly used in racing applications and high-performance street vehicles.

Vehicle Type Applications

Passenger Car Applications: Standard pressure ratings and construction suitable for typical passenger vehicle weight and performance requirements.

Commercial Vehicle Applications: Heavy-duty construction with higher burst pressure ratings and enhanced durability for trucks, buses, and commercial equipment.

Heavy-Duty and Racing Applications: Specialized hoses with maximum pressure ratings, minimal expansion characteristics, and enhanced heat resistance for extreme-duty applications.

Critical Warning Signs Your Brake Hoses Need Attention

Recognizing the early warning signs of brake hose deterioration is crucial for maintaining safe braking performance. Many brake hose failures progress gradually, giving observant drivers and mechanics opportunities to address problems before catastrophic failure occurs.

Visual Inspection Signs

Cracking and Surface Deterioration: External cracking is one of the earliest visible signs of brake hose aging. Look for hairline cracks in the outer rubber cover, particularly near the end fittings where stress concentration is highest. Even small surface cracks can indicate internal deterioration that compromises hose integrity.

Surface checking (small surface cracks) may not immediately affect function but indicates the rubber compound is aging and becoming less flexible. Deep cracks that penetrate the outer cover expose the reinforcement layer to moisture and contamination.

Swelling and Bulging: Brake hose swelling occurs when the inner tube deteriorates and allows brake fluid to penetrate the reinforcement layer. Swollen areas appear as enlarged sections along the hose length and indicate imminent failure. This condition is extremely dangerous as the swollen area is under tremendous stress and may burst without warning.

Localized bulging often occurs near fittings where stress concentration and heat buildup are highest. Any visible swelling requires immediate hose replacement and should never be ignored.

Leaking Brake Fluid: External brake fluid leaks are obvious signs of hose failure requiring immediate attention. Look for:

- Wet spots or stains around hose fittings

- Crystallized brake fluid residue (appears white or yellowish)

- Fresh brake fluid drips under the vehicle

- Any brake fluid leak represents a safety hazard and requires immediate repair

Damaged Fittings or Connections: Inspect the metal end fittings for:

- Corrosion or rust that could weaken the fitting

- Stripped threads on threaded connections

- Deformed or cracked fitting bodies

- Loose connections that allow movement

Performance Symptoms

Spongy Brake Pedal Feel: A soft or spongy brake pedal is often the first performance symptom of brake hose deterioration. When brake hoses begin to expand under pressure, they absorb some of the hydraulic force that should be transmitted to the brake components. This results in increased pedal travel and reduced braking effectiveness.

This symptom may be subtle initially but typically worsens over time as hose deterioration progresses. The sponginess is most noticeable during hard braking when system pressures are highest.

Increased Stopping Distance: Deteriorating brake hoses reduce hydraulic efficiency, requiring greater pedal force and increased stopping distances. This symptom may develop gradually and be difficult to notice until compared to known good braking performance.

Brake Pedal Going to Floor: In severe cases, significantly deteriorated hoses may allow the brake pedal to travel to the floor with little resistance. This indicates major hydraulic pressure loss and requires immediate attention to prevent total brake failure.

Uneven Braking Between Wheels: If one brake hose deteriorates more than others, it can cause uneven braking force distribution. This may result in:

- Vehicle pulling to one side during braking

- Uneven brake pad wear patterns

- Different brake temperatures between sides of the vehicle

Advanced Failure Indicators

Complete Brake Failure Scenarios: Total brake hose failure results in complete loss of hydraulic pressure to affected wheels. This creates an extremely dangerous situation requiring immediate emergency braking procedures.

Signs of impending total failure include:

- Sudden loss of brake pedal firmness

- Visible brake fluid spraying from failed hoses

- Complete loss of braking on affected wheels

Sudden Pressure Loss: Catastrophic hose failure can occur without warning, particularly in severely deteriorated hoses. The sudden release of pressurized brake fluid creates a total loss of braking effectiveness.

Brake Lockup Conditions: In rare cases, internal hose deterioration can create a one-way valve effect, allowing brake pressure to apply but preventing pressure release. This results in brakes that drag or lock up and fail to release properly.

Safety Critical: If you experience any symptoms of brake failure while driving, immediately:

- Use engine braking and downshifting to slow the vehicle

- Apply the parking brake gradually if hydraulic brakes fail completely

- Get the vehicle to a safe location and stop driving immediately

- Have the brake system inspected by a qualified technician before operating the vehicle

Understanding Why Brake Hoses Fail

Brake hose failure rarely occurs without warning. Understanding the root causes of brake hose deterioration helps predict failure modes and implement preventive maintenance strategies. Most brake hose failures result from a combination of age, environmental exposure, and mechanical stress.

Age-Related Deterioration

Rubber Degradation Over Time: Brake hoses are manufactured from synthetic rubber compounds designed for brake fluid compatibility and temperature resistance. However, all rubber compounds undergo molecular changes over time that reduce flexibility and strength.

Typical Lifespan Expectations: Most automotive manufacturers recommend brake hose inspection every 2-3 years and replacement every 6-10 years, depending on operating conditions. However, severe operating conditions may require more frequent replacement. High-mileage vehicles, those operated in extreme climates, or vehicles subjected to heavy braking loads may require earlier replacement.

Environmental Factors: Several environmental conditions accelerate brake hose aging:

- Ozone Exposure: Ground-level ozone attacks rubber compounds, causing surface cracking and hardening

- UV Radiation: Ultraviolet light from sunlight degrades rubber elastomers, particularly in the outer protective layer

- Temperature Cycling: Repeated heating and cooling cycles cause rubber to become brittle and crack

- Road Salt and Chemicals: De-icing chemicals and road treatments can accelerate rubber deterioration

Mechanical Damage

Road Debris Impact: Brake hoses are vulnerable to damage from road debris, particularly stones kicked up by tires. Impact damage may not be immediately visible but can create weak points that lead to future failure.

Common sources of mechanical damage include:

- Stone impacts from road debris

- Contact with suspension components during extreme suspension travel

- Damage during tire changes or suspension work

- Improper routing that allows hose contact with moving parts

Improper Installation Damage: Incorrect installation procedures can damage brake hoses and lead to premature failure:

- Excessive tightening of fittings can distort hose ends

- Incorrect routing can create stress concentrations

- Failure to properly support hoses can cause fatigue failures

- Using incorrect tools can damage fitting surfaces

Abrasion from Contact Points: Brake hoses that contact suspension components, steering components, or body panels during normal operation will eventually wear through. This type of failure is entirely preventable through proper routing and securing.

Chemical Degradation

Incompatible Brake Fluid Effects: While modern brake hoses are designed for compatibility with all DOT-approved brake fluids, using incorrect fluids or contaminated fluids can cause chemical degradation:

- DOT 5 silicone brake fluid should never be mixed with DOT 3/DOT 4 glycol-based fluids

- Petroleum-based fluids (power steering fluid, motor oil) cause immediate rubber swelling and failure

- Contaminated brake fluid containing water or other chemicals accelerates deterioration

Contamination Issues: Brake fluid contamination from several sources can damage hoses:

- Water contamination (hygroscopic absorption) reduces lubrication and increases corrosion

- Petroleum contamination causes rubber swelling and rapid deterioration

- Metal particles from brake system wear can cause internal abrasion

Heat Cycling Damage: Brake systems generate significant heat during operation, particularly during heavy braking. Repeated heating and cooling cycles cause rubber compounds to become brittle and develop micro-cracks.

Excessive heat exposure occurs during:

- Extended mountain driving with frequent braking

- Performance driving or racing applications

- Brake system malfunctions that cause excessive heat generation

Manufacturing Defects

Quality Control Issues: While rare in name-brand components, manufacturing defects can cause premature brake hose failure:

- Inadequate reinforcement layer coverage

- Contaminated rubber compounds

- Improper curing processes that leave weak areas

- Incorrectly machined end fittings

Substandard Materials: Aftermarket brake hoses of questionable quality may use inferior materials:

- Rubber compounds not formulated for brake fluid compatibility

- Inadequate reinforcement materials that cannot handle hydraulic pressure

- Poor-quality end fittings that corrode or fail prematurely

Installation Errors: Improper installation techniques can create conditions leading to early failure:

- Incorrect torque specifications that damage fittings

- Improper routing that creates stress concentrations

- Failure to properly bleed air from the system after installation

How to Properly Inspect Brake Flexible Hoses

Regular brake hose inspection is one of the most important preventive maintenance procedures you can perform. Proper inspection techniques help identify problems before they become safety hazards.

Visual Inspection Process

Step-by-Step Inspection Procedure:

- Prepare the Vehicle: Park on level ground and allow the brake system to cool completely. Never inspect brake components immediately after driving, as they may be extremely hot.

- Initial Overview: Perform a general inspection of all visible brake hoses without removing wheels. Look for obvious signs of damage, leaks, or deterioration.

- Detailed Inspection with Wheels Removed: Remove all wheels to access brake hoses completely. This allows thorough inspection of all hose surfaces and connections.

- Systematic Examination: Inspect each hose from end to end, rotating it to examine all surfaces. Pay particular attention to areas near fittings where stress concentrations occur.

What to Look for at Each Point:

At the Fittings:

- Check for brake fluid leaks or crystallized residue

- Inspect fitting threads for damage or corrosion

- Verify that fittings are properly tightened but not over-torqued

- Look for cracks in the hose where it enters the fitting

Along the Hose Length:

- Surface cracking or checking in the outer rubber layer

- Swelling or bulging that indicates internal deterioration

- Cuts, abrasions, or impact damage from road debris

- Signs of contact with suspension components or other parts

At Mounting Points:

- Proper securing of hose brackets and clips

- Adequate clearance from moving suspension components

- Proper routing that prevents stress concentrations during suspension travel

Tools Needed for Inspection:

- Floor jack and jack stands for safe vehicle lifting

- Flashlight or work light for illuminating inspection areas

- Clean rags for wiping away dirt and debris

- Basic hand tools for removing wheels

- Safety glasses and gloves for protection

Functional Testing Methods

Brake Pedal Feel Assessment: With the engine running and brake booster operational, pump the brake pedal several times and then apply firm, steady pressure. The pedal should feel firm and maintain position without slowly sinking.

A proper brake pedal should:

- Achieve firmness within 2-3 pumps

- Maintain consistent position under steady pressure

- Provide progressive resistance throughout its travel

- Not require excessive force for normal braking

Pressure Testing Procedures: Professional brake pressure testing requires specialized equipment but provides definitive assessment of hydraulic integrity:

- System pressure testing verifies that hoses can contain full system pressure without expansion

- Flow testing ensures hoses don’t restrict brake fluid movement

- These tests should be performed by qualified technicians with appropriate equipment

Movement and Flexibility Checks: With wheels removed, manually move suspension components through their full range of travel while observing brake hose behavior:

- Hoses should flex smoothly without kinking or binding

- No contact should occur between hoses and suspension components

- Hoses should return to their natural position when suspension returns to normal

Professional Diagnostic Techniques

Pressure Gauge Testing: Professional brake system pressure testing using calibrated gauges can identify:

- Maximum system pressure generation capability

- Pressure loss rates that indicate internal leakage

- Uneven pressure distribution between brake circuits

Flow Rate Measurements: Specialized flow testing equipment can detect restrictions in brake hoses that may not be apparent during visual inspection.

Advanced Diagnostic Equipment: Modern brake system analyzers can perform comprehensive testing including:

- Brake force measurement and balance testing

- Hydraulic pressure analysis

- Computerized brake system diagnostics for ABS-equipped vehicles

When working with brake systems, always prioritize safety:

- Use proper vehicle lifting techniques and support

- Wear appropriate personal protective equipment

- Never work under a vehicle supported only by a jack

- Consult professional technicians when you’re unsure about any procedure

For vehicles showing any signs of brake system problems, consider having a comprehensive brake system inspection performed by qualified technicians before attempting repairs.

Brake Hose Replacement: Process and Best Practices

Replacing brake flexible hoses is a critical maintenance procedure that requires careful attention to safety, proper techniques, and quality components. Brake system work involves life-safety components that must be installed correctly.

Pre-Replacement Planning

Tools and Equipment Needed:

- Floor jack and jack stands rated for your vehicle’s weight

- Lug wrench and basic hand tools

- Brake line wrenches (flare nut wrenches) in appropriate sizes

- New brake fluid (DOT 3, DOT 4, or DOT 5.1 as specified)

- Brake bleeding equipment or vacuum pump

- Clean rags and brake parts cleaner

- Safety glasses and nitrile gloves resistant to brake fluid

Parts Selection Criteria: When selecting replacement brake hoses, prioritize quality and proper specifications:

- OEM or equivalent quality hoses that meet DOT FMVSS 106 standards

- Correct length and fitting configuration for your specific vehicle

- Appropriate pressure rating for your vehicle’s brake system

- Hoses designed for your brake fluid type (DOT 3/4/5.1 compatibility)

Workspace Preparation:

- Ensure adequate lighting for detailed work

- Prepare a clean workspace to prevent contamination of brake components

- Have brake fluid disposal containers ready (brake fluid is hazardous waste)

- Ensure proper ventilation as brake fluid vapors can be harmful

Step-by-Step Replacement Process

System Depressurization:

- Turn off the engine and allow the brake system to cool completely

- Pump the brake pedal several times with the engine off to depressurize the brake booster

- Apply the parking brake and secure the vehicle with wheel chocks

Old Hose Removal Procedure:

- Locate the master cylinder reservoir and remove brake fluid to prevent overflow during hose disconnection

- Clean around brake hose fittings to prevent contamination entry

- Using proper brake line wrenches, carefully disconnect the old hose from brake lines and components

- Support brake lines to prevent damage during hose removal

- Remove any mounting brackets or clips securing the hose

New Hose Installation Steps:

- Compare the new hose to the old hose to verify correct part selection

- Install the new hose without twisting or kinking

- Ensure proper routing with adequate clearance from suspension components

- Install mounting brackets and clips to secure the hose properly

- Hand-tighten all fittings before final tightening with proper tools

Proper Torque Specifications:

- Brake line fittings: Typically 10-15 ft-lbs (consult vehicle-specific specifications)

- Banjo bolt connections: Usually 18-25 ft-lbs depending on size

- Over-tightening can damage fittings and cause leaks

- Under-tightening allows leaks and potential fitting separation

System Bleeding Requirements: After brake hose replacement, proper brake system bleeding is essential:

- Fill the master cylinder reservoir with fresh brake fluid

- Bleed air from the brake system using proper sequence (typically farthest from master cylinder first)

- Continue bleeding until no air bubbles appear in the brake fluid

- Test brake pedal feel and firmness before driving

Quality Assurance

Post-Installation Inspection:

- Verify all fittings are properly tightened and leak-free

- Check hose routing for proper clearance and support

- Ensure no twisting or kinking of the new hose

- Confirm brake fluid level is adequate after bleeding

Functional Testing Procedures:

- With the engine running, test brake pedal feel and travel

- Perform low-speed brake tests to verify normal operation

- Check for any signs of brake fluid leaks after initial testing

- Road test the vehicle at low speeds before normal driving

Break-in Period Considerations:

- New brake hoses may require a brief break-in period for optimal performance

- Monitor brake pedal feel during the first few driving cycles

- Re-check all connections for leaks after the first 100 miles of driving

Critical Safety Notes:

- Brake fluid is corrosive to paint and harmful to skin and eyes

- Always use proper personal protective equipment

- Dispose of old brake fluid according to local environmental regulations

- Never reuse brake fluid that has been bled from the system

- If you’re uncertain about any procedure, consult a professional technician

For complex brake system work or if you encounter unexpected problems during replacement, professional brake system service ensures safety and proper function. Consider having your brake system professionally serviced if you notice any signs of brake booster problems or other brake system issues during hose replacement.

Extending Brake Hose Life Through Proper Maintenance

Proactive maintenance significantly extends brake hose service life and helps prevent unexpected failures. Regular maintenance is far more cost-effective than emergency repairs and helps ensure safe braking performance.

Regular Inspection Schedule

Recommended Inspection Intervals:

- Visual inspection every 6 months or during routine maintenance

- Comprehensive inspection annually or every 12,000 miles

- Professional brake system inspection every 2-3 years

- Immediate inspection after any brake system work or suspected problems

Seasonal Inspection Considerations:

- Pre-winter inspection to identify potential problems before harsh weather

- Post-winter inspection to assess damage from road salt and chemicals

- Pre-summer inspection before vacation travel or extended driving

- Post-severe service inspection after towing, mountain driving, or performance use

Mileage-Based Replacement Guidelines: While age is typically more critical than mileage for brake hoses, consider replacement:

- Every 100,000-150,000 miles under normal conditions

- Every 75,000-100,000 miles under severe service conditions

- Sooner if visual inspection reveals deterioration

Preventive Measures

Proper Brake Fluid Maintenance:

- Change brake fluid every 2-3 years or according to manufacturer recommendations

- Use only the specified brake fluid type (DOT 3, DOT 4, or DOT 5.1)

- Never mix different brake fluid types

- Keep brake fluid containers sealed to prevent moisture absorption

Protection from Environmental Factors:

- Park in covered areas when possible to reduce UV and ozone exposure

- Rinse undercarriage regularly to remove road salt and chemicals

- Apply protective coatings if available for your specific vehicle

- Avoid parking near sources of ozone (electrical equipment, welding areas)

Avoiding Mechanical Damage:

- Drive carefully on rough roads to minimize road debris impact

- Ensure proper tire inflation to reduce tire-thrown debris

- Have suspension components inspected to prevent contact with brake hoses

- Route aftermarket accessories carefully to avoid brake hose interference

Early Detection Strategies

Warning Sign Recognition: Train yourself to recognize early signs of brake hose deterioration:

- Changes in brake pedal feel or travel

- Visible surface checking or cracking

- Any signs of brake fluid leaks or seepage

- Unusual brake noises or performance changes

Performance Monitoring:

- Note changes in braking effectiveness or pedal feel

- Pay attention to vehicle pulling during braking

- Monitor brake component temperatures after driving

- Keep records of brake system maintenance and inspection results

Maintenance Record Keeping: Document brake system maintenance including:

- Inspection dates and findings

- Brake fluid change intervals

- Any brake system repairs or component replacements

- Performance issues or concerns noted during driving

For comprehensive brake system maintenance, consider having a professional evaluation that includes inspection of brake calipers, ABS components, and other critical brake system elements.

Understanding Brake Hose Replacement Costs

Planning for brake hose maintenance helps ensure timely replacement and prevents more expensive emergency repairs. Understanding cost factors helps make informed decisions about maintenance timing and service options.

Parts Cost Factors

OEM vs Aftermarket Options:

- OEM (Original Equipment Manufacturer) hoses typically cost $25-75 per hose depending on vehicle

- Quality aftermarket hoses range from $15-50 per hose

- Premium performance hoses (stainless steel braided) cost $50-150 per hose

- Budget aftermarket options under $15 may compromise safety and durability

Quality Level Differences:

- Economy hoses may meet minimum DOT standards but lack durability

- Standard replacement hoses offer good value for normal driving conditions

- Premium hoses provide enhanced durability and performance characteristics

- Racing/performance hoses designed for extreme conditions cost significantly more

Vehicle-Specific Requirements:

- Luxury and imported vehicles often have higher parts costs

- Vehicles with ABS may require specialized hoses

- Commercial vehicles and trucks typically require heavy-duty hoses

- Older vehicles may have limited aftermarket availability, increasing costs

Labor Considerations

Professional Service Costs:

- Typical labor charges range from $75-150 per hose including bleeding

- Additional charges may apply for seized fittings or difficult access

- Total professional replacement typically costs $150-400 per hose installed

- Fleet or multiple hose replacement may offer economies of scale

DIY Time Investment:

- Single hose replacement typically requires 2-4 hours for DIY mechanics

- Additional time needed for brake system bleeding and testing

- Learning curve for first-time brake system work increases time requirements

- Proper tools and workspace setup add to overall time investment

Complexity Factors:

- Front hoses generally easier to access than rear hoses

- ABS-equipped vehicles may require special bleeding procedures

- Integrated hose/bracket assemblies increase replacement complexity

- Corroded fittings may require additional time and specialized tools

Long-term Value

Safety Investment Perspective: Brake hose replacement represents a critical safety investment:

- Prevents catastrophic brake system failure and potential accidents

- Maintains optimal braking performance and vehicle control

- Protects other brake system components from damage

- Provides peace of mind during family travel and daily driving

Preventive vs Emergency Replacement:

- Scheduled maintenance replacement costs 30-50% less than emergency service

- Emergency failures often occur at inconvenient times and locations

- Preventive replacement prevents collateral damage to other brake components

- Scheduled replacement allows time for proper parts selection and service planning

Total System Impact: Quality brake hoses protect the entire brake system:

- Prevent brake fluid contamination from failed hoses

- Maintain proper hydraulic pressure distribution

- Protect expensive brake components like ABS modules and calipers

- Ensure optimal performance of related brake system components

For budget-conscious vehicle owners, consider having brake hose inspection performed during routine maintenance to identify replacement needs before emergency situations arise. Professional inspection can help prioritize which hoses need immediate attention versus those that can be scheduled for future replacement.

Critical Safety and Regulatory Aspects

Brake flexible hoses are regulated safety components that must meet stringent standards for public road use. Understanding safety requirements and legal implications helps ensure proper selection and installation of brake system components.

DOT Regulations and Compliance

Federal Motor Vehicle Safety Standard (FMVSS) 106: All brake hoses sold for highway use in the United States must meet FMVSS 106 requirements, which specify:

- Minimum burst pressure ratings (typically 4,000 PSI for passenger vehicles)

- Compatibility requirements with DOT-approved brake fluids

- Temperature performance specifications (-40°F to +300°F)

- Flexibility and durability testing standards

DOT Marking Requirements: Compliant brake hoses must display permanent markings including:

- DOT designation indicating compliance with federal standards

- Manufacturer identification and date code

- Pressure rating and temperature specifications

- Brake fluid compatibility information (DOT 3, DOT 4, DOT 5.1)

Import and Aftermarket Compliance:

- All brake hoses must meet DOT standards regardless of origin

- Aftermarket manufacturers must certify compliance with federal standards

- Racing or “off-road only” hoses may not meet DOT requirements for street use

- Using non-compliant brake hoses may violate federal safety regulations

Safety Standards and Certifications

Industry Testing Standards: Beyond basic DOT requirements, quality brake hoses undergo additional testing:

- Society of Automotive Engineers (SAE) standard testing

- Automotive industry supplier quality certifications

- Extended temperature and pressure cycling tests

- Ozone resistance and aging tests

Professional Installation Requirements: Many jurisdictions require professional installation of safety-critical brake components:

- Commercial vehicle brake work often requires certified technicians

- Some insurance policies may require professional installation documentation

- Warranty coverage may depend on proper professional installation

- DIY installation assumes full responsibility for safety and performance

Legal Liability Considerations

Vehicle Owner Responsibilities: Vehicle owners have legal responsibilities for brake system maintenance:

- Regular inspection and maintenance of brake system components

- Prompt attention to known brake system problems

- Use of appropriate replacement parts and fluids

- Compliance with applicable safety regulations and standards

Professional Service Standards: Professional brake system service providers must:

- Use appropriate replacement parts that meet regulatory standards

- Follow manufacturer-specified procedures and torque specifications

- Perform proper system bleeding and testing after component replacement

- Maintain appropriate insurance and certifications for brake system work

Documentation Importance: Proper documentation of brake system maintenance helps establish:

- Compliance with reasonable maintenance standards in liability situations

- Evidence of proper care and attention to safety-critical components

- Service history for warranty claims and insurance purposes

- Professional service records that demonstrate due diligence

Professional Consultation Requirements

When Professional Help is Mandatory: Certain brake system conditions require immediate professional attention:

- Any symptoms of brake failure or severely compromised braking performance

- Complex ABS-related brake system problems

- Brake system contamination or fluid compatibility issues

- Multiple brake system components requiring simultaneous replacement

Recommended Professional Consultation:

- Annual comprehensive brake system inspection

- Brake system work on commercial or heavy-duty vehicles

- Performance modifications to brake systems

- Any brake system work you’re uncertain about performing correctly

Emergency Procedures: If brake system failure occurs while driving:

- Remain calm and avoid panic braking

- Use engine braking and downshifting to reduce speed

- Apply parking brake gradually if hydraulic brakes fail completely

- Get to a safe location immediately and stop driving

- Have the vehicle towed for professional brake system repair

Essential Points for Brake Hose Safety and Maintenance

Understanding brake flexible hoses and maintaining them properly is crucial for vehicle safety and reliable braking performance. These critical components deserve the same attention as brake pads and other more visible brake system parts.

Critical Safety Messages

Brake Hoses Are Life-Safety Components: Never compromise on quality or defer necessary maintenance of brake flexible hoses. A failed brake hose can result in partial or complete brake system failure, creating extremely dangerous driving conditions that endanger vehicle occupants and other road users.

Early Detection Saves Lives: Regular inspection and early recognition of brake hose deterioration symptoms allows for planned replacement before emergency situations occur. Most brake hose failures provide warning signs if you know what to look for.

Quality Matters: Always use brake hoses that meet or exceed DOT FMVSS 106 standards. Bargain brake hoses may save money initially but can compromise safety and lead to premature failure. The cost difference between quality and economy brake hoses is minimal compared to the potential consequences of failure.

Key Maintenance Recommendations

Establish a Regular Inspection Schedule:

- Visual inspection every 6 months during routine maintenance

- Annual comprehensive brake system inspection

- Immediate inspection after any brake system work or suspected problems

- Professional evaluation every 2-3 years or as recommended by your technician

Maintain Proper Brake Fluid:

- Change brake fluid every 2-3 years to prevent contamination-related hose deterioration

- Use only the brake fluid type specified for your vehicle

- Never mix different brake fluid types or use non-brake fluids in the system

- Keep brake fluid containers sealed and store in appropriate conditions

Address Problems Immediately:

- Never ignore signs of brake system problems or unusual brake pedal feel

- Stop driving if you experience symptoms of brake system failure

- Have suspected brake problems diagnosed professionally before they become safety hazards

- Replace brake hoses at the first signs of deterioration rather than waiting for failure

When to Seek Professional Help

Immediate Professional Attention Required:

- Any symptoms of brake failure or severely reduced braking effectiveness

- Visible brake fluid leaks from any brake system component

- Brake pedal going to the floor or feeling unusually soft

- Vehicle pulling strongly to one side during braking

- Any brake system warning lights or unusual brake-related noises

Recommended Professional Services:

- Complex brake system diagnosis requiring specialized equipment

- Brake system work on ABS-equipped vehicles requiring special procedures

- Multiple brake system component replacement or major brake system service

- Annual comprehensive brake system inspection and maintenance planning

Professional Consultation Benefits:

- Access to specialized diagnostic equipment and training

- Knowledge of vehicle-specific procedures and specifications

- Proper tools and workspace for safe brake system service

- Warranty coverage and professional liability insurance

- Peace of mind knowing critical safety work is performed correctly

Final Safety Reminders

Your Responsibility as a Vehicle Owner: Maintaining your vehicle’s brake system is ultimately your responsibility as the vehicle owner. Regular attention to brake hose condition and prompt response to warning signs helps ensure safe operation for you, your passengers, and other road users.

The Cost of Prevention vs. Emergency Repair: Planned brake hose replacement during scheduled maintenance costs significantly less than emergency repair and prevents the inconvenience and danger of brake system failure. The small investment in preventive maintenance provides enormous returns in safety and peace of mind.

Resources for Continued Learning: Stay informed about brake system maintenance through:

- Vehicle manufacturer maintenance recommendations and technical bulletins

- Professional brake system service providers who can provide guidance specific to your vehicle

- Reputable automotive technical publications and training resources

- Brake system educational resources that help you understand your vehicle’s braking system

Information Disclaimer: This information is provided for educational and reference purposes only. Always implement brake system procedures at your own risk and responsibility. When in doubt about any brake system work, consult with qualified professional technicians who have the proper training, tools, and experience to ensure safe and correct brake system service.

For additional brake system information and resources, explore related topics including ABS system operation, brake bleeding procedures, and comprehensive brake system diagnosis. Remember that brake system work involves critical safety components that require proper knowledge, tools, and procedures for safe and effective service.

Contact Information: For questions about brake system maintenance or to locate qualified brake system service providers in your area, contact professional automotive service centers or visit Repairs Advisor for additional resources and technical support.