Modern vehicles depend on sophisticated electronic systems to keep you safe on the road, and few components are more critical than the ABS control module. This small but mighty computer serves as the brain of your anti-lock braking system, making split-second decisions that can mean the difference between a controlled stop and a dangerous skid. When your ABS control module fails, it doesn’t just turn on a dashboard light – it compromises your vehicle’s ability to stop safely in emergency situations.

CRITICAL SAFETY WARNING: ABS control module issues directly affect vehicle braking performance. Any problems with this system require immediate professional attention. Never ignore ABS warning lights or changes in brake pedal feel, as these symptoms indicate potential safety hazards that could lead to accidents.

Whether you’re a DIY enthusiast trying to understand that glowing ABS light on your dashboard, a professional mechanic diagnosing brake system problems, or a business owner managing vehicle maintenance costs, this comprehensive guide will help you understand everything about ABS control modules. We’ll cover how they work, how to identify problems, and most importantly, when to seek professional help to ensure your safety and the safety of others on the road.

Understanding the ABS Control Module

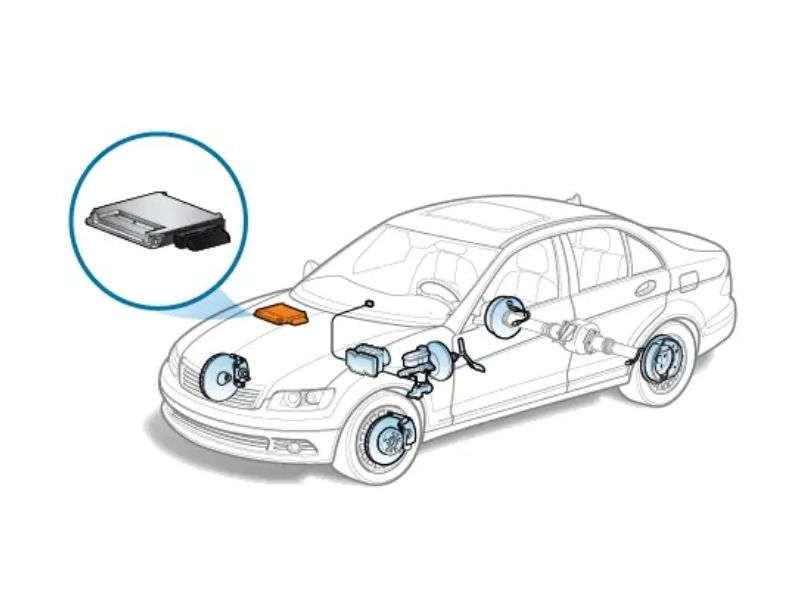

The ABS control module is an electronic control unit (ECU) that serves as the command center for your vehicle’s anti-lock braking system. Think of it as a sophisticated computer that constantly monitors your wheels and makes rapid-fire decisions to prevent dangerous wheel lockup during hard braking. This isn’t just a convenience feature – it’s a critical safety system that has prevented countless accidents since becoming standard equipment on modern vehicles.

The Control Process in Action:

Your ABS control module operates through a continuous four-step process that happens faster than you can blink. First, it collects data by constantly monitoring input from wheel speed sensors at each corner of your vehicle, measuring how fast each wheel is rotating dozens of times per second. Next, it analyzes this information to detect when one or more wheels are about to lock up during braking, comparing the rotation speeds and looking for dangerous disparities. When a potential lockup is detected, the module responds by sending commands to the hydraulic control unit to rapidly modulate brake pressure to the affected wheel or wheels. Finally, it maintains a feedback loop, continuously adjusting pressure multiple times per second until the dangerous condition passes.

Types of ABS Control Modules:

Not all ABS systems are created equal, and understanding the differences can help you better diagnose problems and understand repair costs. Separate module systems use a standalone ABS control unit that’s mounted independently from other brake components, making diagnosis and replacement relatively straightforward. Integrated systems combine the control module with the hydraulic control unit (HCU) in one assembly, which can be more expensive to replace but often more reliable. Advanced systems found in newer vehicles integrate ABS control with stability control, traction management, and even adaptive cruise control, making them more complex but also more capable.

The magic happens through the interaction of several key components. ABS Wheel Speed Sensor units provide the rotational speed data that feeds the control module’s decision-making process. The hydraulic control unit executes the pressure modulation commands from the control module, while brake lines carry the modulated hydraulic pressure to each wheel. The entire system communicates through the vehicle’s network with other control systems, sharing information about vehicle speed, steering input, and driver intentions.

For a deeper understanding of how these components work together, explore our comprehensive guide on Anti-lock Braking System (ABS): Why It Is Important and How It Works.

Location and Physical Characteristics

Finding your ABS control module is the first step in any diagnostic or repair procedure, but the location varies significantly depending on your vehicle’s make, model, and year. Most commonly, you’ll find the module mounted in the engine bay, typically attached to or near the brake line distribution block where it can easily access the hydraulic system. This location provides the necessary connections to both the electrical system and brake lines while offering some protection from road debris and moisture.

In some older systems, particularly those from the 1990s and early 2000s, the ABS control module might be located under the dashboard, usually on the driver’s side near the brake pedal assembly. European vehicles sometimes mount the module near the master cylinder or on the firewall, integrating it closely with other brake system components. Regardless of location, the module is always positioned where it can be protected from environmental extremes while maintaining easy access to the brake hydraulic system.

Physical Description and Identification:

A typical ABS control module is a rectangular metal or heavy-duty plastic housing, usually measuring between 4 and 6 inches in length. You’ll immediately notice multiple electrical connectors – usually two to four – along with several brake line fittings that connect directly to the hydraulic system. The module will have part numbers and manufacturer markings visible on its surface, which are crucial for ordering the correct replacement unit.

Access to the module may require removing other components such as the battery, air filter housing, or engine covers. Some vehicles mount the module in locations that require significant disassembly to reach, which directly affects labor costs for diagnosis and replacement. Always consult your specific vehicle’s service manual before attempting to locate or service the ABS control module.

Vehicle-Specific Considerations:

Different manufacturers have distinct approaches to ABS module placement and design. Domestic vehicles like those from Ford, General Motors, and Chrysler often use separate, easily accessible modules that can be serviced without extensive disassembly. For specific procedures on your Ford vehicle, consult our FORD Manuals section for detailed service information.

European manufacturers such as BMW, Mercedes-Benz, and Volkswagen frequently integrate ABS modules with other systems, requiring specialized tools and procedures for service. Japanese manufacturers like Toyota and Honda typically position modules for good accessibility while maintaining reliable environmental protection. Our TOYOTA Manuals and HONDA Manuals sections provide model-specific location information.

For American truck owners, CHEVROLET Manuals offer detailed diagrams showing module locations in various truck and SUV models, where placement often differs from passenger cars due to frame construction and component packaging requirements.

Signs and Symptoms of ABS Control Module Failure

Recognizing the early signs of ABS control module failure can prevent dangerous situations and potentially save you from more expensive repairs. The symptoms typically develop gradually, giving you warning signs before complete system failure occurs. However, some failures can happen suddenly, making it crucial to understand what to watch for and when to seek immediate professional help.

Dashboard Warning Indicators:

The most obvious sign of ABS trouble is the illumination of warning lights on your dashboard. The ABS warning light – typically an amber or yellow light that says “ABS” or shows a circular arrow symbol – indicates the system has detected a malfunction and disabled itself. When this light comes on, your regular brakes will still work, but you’ll lose the anti-lock function that prevents wheel lockup.

You might also see the red brake system warning light illuminate simultaneously, especially if the problem affects the overall brake system hydraulic pressure. Modern vehicles with traction control will often display the traction control light as well, since these systems share components with the ABS. Electronic stability control warnings may also appear, as advanced systems integrate multiple safety functions through the ABS control module.

Brake Performance Changes:

Changes in how your brake pedal feels or responds are serious warning signs that demand immediate attention. You might notice a gradual increase in the force required to achieve normal braking, a condition that worsens over time as the module’s ability to regulate pressure deteriorates. An unresponsive pedal that becomes hard or fails to engage the brakes properly represents an emergency situation requiring immediate professional service.

A spongy or mushy pedal feel, where the pedal travels further than normal before engaging the brakes, often indicates problems with the hydraulic control portion of the ABS system. Unusual vibration or pulsing during normal braking – not the normal ABS pulsation during emergency stops – suggests the module is malfunctioning and inappropriately activating the anti-lock function.

Wheel Lockup Problems:

One of the most dangerous symptoms is premature wheel locking during moderate braking, especially on wet or slippery surfaces. When the ABS control module fails, it cannot prevent wheels from locking up, leading to loss of steering control and potential skidding. You might experience longer stopping distances, particularly noticeable in emergency braking situations where ABS normally provides the greatest benefit.

System Behavior Abnormalities:

Faulty ABS control modules can cause erratic system behavior that’s both annoying and dangerous. Random brake pulsation during normal driving, when you’re not even pressing the brake pedal, indicates the module is sending inappropriate commands to the hydraulic system. Clicking or grinding noises from the brake system, particularly from the area around the ABS module, suggest internal component failures.

Some drivers experience brake pedal pumping without any input from them, a condition where the ABS system activates inappropriately on dry pavement during normal braking. This false activation not only affects braking performance but can be extremely disconcerting when you’re not expecting it.

Progressive Symptom Development:

ABS control module problems typically develop in stages, giving you opportunities to address issues before they become critical. In the early stage, you might notice occasional ABS light illumination that comes and goes, slight increases in brake pedal effort, or minor system hesitation during operation.

The advanced stage brings constant warning lights, significant brake performance degradation, and complete loss of ABS functionality. At this point, while your regular brakes may still work, you’ve lost the safety benefit of anti-lock braking and should seek professional service immediately.

The critical stage represents a potential brake system emergency, with safety systems completely disabled and possible brake failure risk. If you reach this stage, stop driving immediately and have your vehicle professionally diagnosed and repaired.

For more information about related brake system problems, check out our articles on Signs Your ABS Valve Assembly Is Failing and ABS Control Module: The Brains Behind Your Safe Stops.

Common Causes of ABS Control Module Failure

Understanding why ABS control modules fail helps you prevent problems and make informed repair decisions. These sophisticated electronic components face harsh operating conditions and multiple stress factors that can lead to failure over time. While some causes are unavoidable aging processes, others result from maintenance neglect or environmental factors you can control.

Electronic Component Degradation:

Modern ABS control modules contain complex circuit boards with hundreds of electronic components, each subject to failure over time. Solder joint failures represent one of the most common problems, caused by repeated thermal cycling as the module heats up during operation and cools down when parked. The constant expansion and contraction eventually causes solder connections to crack, creating intermittent or permanent electrical failures.

Capacitor degradation is another age-related issue, as these components gradually lose their ability to store and release electrical energy properly. When capacitors fail, the module may experience power supply problems, signal processing errors, or complete shutdown. Integrated circuit component failure can occur due to electrical overstress, manufacturing defects, or simply reaching the end of their designed lifespan.

Moisture intrusion represents a particularly damaging problem, as water infiltration through damaged seals causes corrosion of internal components. Once moisture enters the module, it creates a cascade of problems including short circuits, component corrosion, and accelerated failure of other electronic parts.

Environmental Factors:

The engine bay environment subjects ABS control modules to extreme conditions that stress electronic components. Heat damage from prolonged exposure to high temperatures can cause component failure, particularly in modules mounted close to the engine or exhaust system. Inadequate cooling or ventilation compounds this problem, as excessive heat accelerates the aging process of electronic components.

Thermal stress from repeated heating and cooling cycles affects not just solder joints but also the physical components themselves, causing expansion and contraction that can crack circuit boards or damage component mounting. Road salt and chemical exposure create corrosion problems, particularly in regions where winter road treatments are common.

Hydraulic System Problems:

The intimate connection between the ABS control module and the brake hydraulic system means that brake fluid problems directly affect module health. Contaminated brake fluid can damage seals and internal components, while moisture in the brake fluid creates internal corrosion that affects both hydraulic and electronic portions of the system.

Using the wrong type of brake fluid can damage seals and cause pressure regulation problems, while air in the hydraulic lines affects pressure readings and can cause the module to malfunction. Excessive hydraulic pressure from system problems can damage internal components, while pressure sensor failures prevent the module from accurately controlling brake pressure.

Age and Mileage Factors:

Most ABS control modules have a typical lifespan of 10 to 15 years under normal operating conditions, though this varies significantly based on operating environment and maintenance history. High-mileage vehicles experience more failures due to accumulated wear and exposure to stress factors over time.

Frequent ABS activation actually accelerates wear on internal components, as each activation cycle stresses the electronic and hydraulic components. This is why vehicles driven in conditions that frequently trigger ABS – such as mountain driving or areas with frequent precipitation – may experience shorter module lifespans.

Component fatigue from repeated cycling affects both electronic switches and hydraulic valves within the module. Like any mechanical or electronic device, repeated operation eventually leads to wear and failure of internal components.

Maintenance-Related Causes:

Poor maintenance practices significantly contribute to premature ABS control module failure. Neglecting regular brake fluid changes allows moisture and contaminants to build up in the system, directly affecting module health. Brake fluid should be changed every 2-3 years to prevent internal corrosion and maintain proper system operation.

Ignoring early warning signs often leads to cascade failures, where a small problem becomes a major system failure because it wasn’t addressed promptly. When the ABS light comes on, it’s indicating a problem that needs attention – continuing to drive without diagnosis can cause additional damage.

Improper service procedures during other brake work can damage the control module or its connections, while using incorrect replacement parts can cause compatibility problems or premature failure. Always ensure that any brake system service is performed by qualified professionals using proper procedures and quality parts.

Diagnostic Procedures and Tools

Proper diagnosis of ABS control module problems requires a systematic approach combining visual inspection, electronic testing, and functional evaluation. While some basic checks can help identify obvious problems, comprehensive diagnosis demands professional equipment and expertise. Never attempt to diagnose brake system problems without proper knowledge and tools, as incorrect procedures can compromise safety.

Initial Visual Inspection:

Before any diagnostic work, ensure your safety by parking on a level surface with the parking brake engaged and allowing the brake system to cool completely. Hot brake components can cause burns, and pressurized brake fluid can be dangerous. Always wear safety glasses and gloves when working around brake systems, and never work under a vehicle supported only by a jack.

Start with an external examination of the ABS control module and surrounding area. Look for obvious physical damage such as cracked housing, damaged electrical connectors, or signs of impact. Check for brake fluid leaks around the module area, as hydraulic leaks can damage electronic components and indicate broader system problems.

Inspect electrical connections for corrosion, looseness, or physical damage. Corroded connections can cause intermittent problems that are difficult to diagnose, while loose connections may create sporadic symptoms. Verify that the module is properly mounted and supported, as vibration from loose mounting can cause internal damage over time.

Professional Diagnostic Equipment:

Comprehensive ABS diagnosis requires specialized equipment that most DIY enthusiasts don’t possess. An OBD-II scanner capable of reading ABS codes is essential, but not all generic scanners can access ABS systems. Professional-grade scanners or manufacturer-specific diagnostic tools provide the most comprehensive information about system operation and stored fault codes.

A digital multimeter is crucial for electrical circuit testing, allowing technicians to verify power supply voltages, check circuit continuity, and measure component resistance. More advanced diagnosis may require an oscilloscope for analyzing sensor signals and communication between components, helping identify intermittent problems that don’t show up in basic testing.

Diagnostic Code Retrieval:

The first step in electronic diagnosis involves connecting a scanner to the vehicle’s diagnostic port and accessing the ABS system menu. Modern vehicles store fault codes that provide specific information about detected problems, along with freeze frame data that captures operating conditions when the fault occurred.

Common diagnostic trouble codes include C0040-C0099 series codes related to wheel speed sensor problems, C0100-C0199 codes indicating ABS control module internal faults, C0200-C0299 codes pointing to hydraulic system problems, and C0300-C0399 codes showing communication errors between modules.

Electrical System Testing:

Proper ABS operation depends on clean electrical power and reliable ground connections. Testing should verify battery voltage of at least 12.6 volts at rest and 13.5-14.5 volts with the engine running. The charging system must provide stable power, as voltage fluctuations can cause control module malfunctions.

Check for voltage drops in supply circuits, as even small voltage losses can affect sensitive electronic components. Test communication network integrity, as modern ABS systems communicate with other vehicle modules and require proper network operation. Verify output signals to hydraulic valves and measure resistance of internal circuits to identify component failures.

Functional Testing Procedures:

Static testing includes verifying that the ABS warning light performs its bulb check function when the key is turned on, confirming that the system completes its self-test cycle, and checking for stored codes that might not trigger warning lights. Component resistance measurements can identify failed internal components even when they don’t generate fault codes.

Dynamic testing involves test driving the vehicle with a scanner connected to monitor live data during operation. This allows technicians to observe system behavior under actual operating conditions and verify proper activation during controlled testing. However, this type of testing should only be performed by qualified technicians in controlled environments.

SAFETY WARNING: Never attempt to intentionally activate ABS on public roads. Dynamic testing requires controlled conditions and professional expertise to ensure safety. Improper testing procedures can cause accidents or damage to the vehicle.

For comprehensive diagnostic information and related brake system troubleshooting, visit our Diagnostics & Troubleshooting section for additional resources and guides.

Professional Repair vs. Replacement Options

When your ABS control module fails, you face several options ranging from repair to complete replacement. Understanding these choices helps you make informed decisions based on your vehicle’s condition, your budget, and safety requirements. Each option has distinct advantages and limitations that affect both cost and long-term reliability.

When Repair is Possible:

ABS control module repair is often possible when the failure involves software corruption, loose electrical connections, minor circuit board issues, or calibration problems. Many modules fail due to relatively simple problems like corrupted programming or damaged solder joints that can be repaired by specialized shops.

The repair process typically involves removing the module from the vehicle and disconnecting the battery along with all electrical and hydraulic connections. The module then undergoes bench testing using specialized electronic analysis equipment to identify the specific failure points. Technicians replace faulty internal components such as capacitors, integrated circuits, or repair damaged circuit board traces.

After component replacement, the module receives new programming with correct software and calibration data specific to your vehicle. Finally, comprehensive testing verifies proper operation before reinstallation. This process typically takes 3-5 business days and costs significantly less than replacement.

Cost Advantages of Repair:

Module repair typically costs between $150 and $350, including core exchange in most cases. This represents substantial savings compared to replacement, especially for expensive luxury vehicle modules. Most reputable repair services provide warranty coverage of 6-12 months, giving you protection against recurring problems.

Repair also offers environmental benefits by keeping electronic components out of landfills and reducing the demand for new manufacturing. For older vehicles where replacement modules are expensive or difficult to find, repair may be the only viable option.

When Replacement is Necessary:

Replacement becomes necessary when the module suffers severe physical damage, multiple internal component failures, extensive water damage with corrosion, or when dealing with obsolete modules that no longer have repair support. Physical damage from accidents, fire, or electrical surges often makes repair impossible or uneconomical.

Replacement Options and Considerations:

New OEM modules represent the highest quality option, offering original equipment manufacturer parts with full warranty coverage. These units cost between $800 and $2,500 depending on the vehicle, but provide the best reliability and longest service life. New modules may require special programming and typically include comprehensive warranty coverage.

Remanufactured units offer quality similar to new at lower cost, typically ranging from $400 to $1,200. These modules undergo factory rebuilding processes that replace worn components and update software to current specifications. Most include core exchange programs and provide 1-2 year warranties.

Used modules from salvage yards represent the lowest initial cost option at $100-$500, but offer no warranty or very limited coverage. Compatibility verification is essential, as ABS modules are often programmed for specific vehicle configurations. Used modules may still require programming and don’t guarantee long-term reliability.

Programming and Calibration Requirements:

Modern ABS control modules require extensive programming after installation, including vehicle identification number (VIN) programming for anti-theft integration, brake system calibration data specific to your vehicle’s configuration, and regional specification settings that vary by market.

This programming requires manufacturer diagnostic software, internet connectivity for accessing the latest updates, security access codes that prevent unauthorized modifications, and specialized programming hardware that most independent shops don’t possess. The complexity of these requirements makes professional installation essential.

Cost Analysis and Decision Factors:

Total replacement costs vary dramatically based on several factors. Parts costs range from $240 for simple aftermarket units to $2,500 for complex OEM modules. Labor charges typically run 1-3 hours at $100-150 per hour, while programming fees can add $100-200 at dealership service centers. Brake system bleeding adds another $50-100 to ensure proper operation.

The total typical range spans from $500 to $3,000, with luxury and foreign vehicles commanding the highest prices. Vehicle make and model significantly affect costs, as some manufacturers use proprietary systems that require expensive OEM parts. Module type also matters, with integrated systems costing more than simple standalone units.

Geographic location affects labor rates, with metropolitan areas typically charging higher rates than rural locations. Your choice of service provider also impacts cost, as dealership rates usually exceed independent shop pricing, though dealerships may be necessary for complex programming requirements.

Decision-Making Guidelines:

For high-value vehicles or those under warranty, new OEM modules provide the best long-term value and maintain vehicle integrity. Older vehicles in good condition benefit from remanufactured modules that offer substantial cost savings with good reliability. When budget constraints are primary concerns, consider repair options first, as they often provide the most economical solution.

Never compromise on safety by choosing the cheapest option regardless of quality. The ABS control module directly affects your ability to stop safely, making reliability more important than initial cost savings. Consider the total cost of ownership, including warranty coverage and potential future repairs, when making your decision.

Installation and Service Considerations

ABS control module installation is a complex procedure that requires professional expertise, specialized tools, and manufacturer-specific knowledge. While the concept might seem straightforward – disconnect the old module and install the new one – the reality involves intricate hydraulic connections, electronic programming, and safety-critical system testing that demands professional service.

Why Professional Installation is Essential:

The complexity of modern ABS systems makes professional installation non-negotiable for safety reasons. Hydraulic connections require precise torque specifications to prevent leaks and ensure proper pressure regulation. Incorrect torque can cause brake fluid leaks, pressure loss, or even complete brake failure – conditions that can be fatal in emergency situations.

Electronic programming represents another critical requirement that demands manufacturer software and specialized knowledge. Modern ABS modules must be programmed with vehicle-specific data including VIN numbers, brake system specifications, and regional settings. Incorrect programming can cause system malfunctions, warning light problems, or complete failure of safety systems.

Brake system bleeding after ABS module replacement requires specialized procedures that differ significantly from standard brake bleeding. Many systems require scan tool activation of internal solenoids and valves to properly purge air from the system. Improper bleeding can cause brake pedal problems, reduced braking effectiveness, or complete brake failure.

Pre-Installation Requirements:

Before installation begins, technicians must perform a complete brake system inspection to identify any related problems that could affect the new module. This includes checking brake fluid condition, inspecting brake lines and connections, and verifying proper operation of wheel speed sensors and other ABS components.

Brake fluid replacement is mandatory during ABS module service, as contaminated fluid can damage the new module and cause premature failure. The entire system must be flushed with fresh fluid meeting manufacturer specifications to ensure optimal performance and longevity.

Documentation of vehicle configuration data is crucial before removing the old module, as this information may be needed for programming the replacement unit. This includes recording VIN numbers, brake system specifications, and any special equipment or option codes that affect ABS operation.

Installation Process Overview:

The installation process begins with proper vehicle preparation, including disconnecting the battery to prevent electrical damage and relieving brake system pressure according to manufacturer procedures. Access panels or components may require removal to reach the module, and all connections should be photographed for reference during reassembly.

Module removal involves carefully disconnecting electrical connectors and removing brake line connections using proper procedures to prevent contamination. The old module is unbolted from its mounting bracket while protecting brake lines from dirt and moisture intrusion.

Installation of the new module reverses this process, mounting it to manufacturer specifications and connecting brake lines with new crush washers or seals as required. Electrical connections must be properly seated and secured to prevent corrosion or vibration damage. All connections require verification to ensure proper seating and security.

System Completion Procedures:

After physical installation, the brake fluid reservoir must be filled and the entire brake system thoroughly bled according to manufacturer procedures. This often requires specialized bleeding sequences that activate ABS solenoids and valves to purge air from all portions of the system.

Programming the new module involves connecting manufacturer diagnostic equipment and entering vehicle-specific data including VIN programming for theft protection, brake system calibration data, and system adaptation procedures. This process can take several hours and requires internet connectivity for accessing current software versions.

Post-Installation Quality Assurance:

Comprehensive testing verifies proper installation and system operation. This includes dashboard warning light verification to ensure all systems recognize the new module, followed by careful test driving with gradual brake testing to verify normal operation.

ABS system activation testing must be performed in a controlled environment to verify proper anti-lock function without compromising safety. A final diagnostic scan checks for stored codes and verifies that all systems are operating within normal parameters.

Warranty and Documentation Requirements:

Professional installation includes comprehensive warranty coverage for both parts and labor, typically ranging from 90 days to 1 year for labor and 1-3 years for parts. Proper documentation includes recording part numbers and serial numbers, verifying programming completion, and providing customer education on system operation.

Complete service records are essential for warranty claims and future service needs. This documentation should include all work performed, parts used, and verification of proper system operation.

For additional information about brake system service and maintenance, explore our comprehensive Brakes resource section, which covers all aspects of brake system care and repair.

Prevention and Maintenance Tips

Preventing ABS control module failure is far more cost-effective than dealing with repairs or replacement. While some failures result from normal aging that can’t be prevented, many problems stem from maintenance neglect or operating conditions that you can control. A proactive approach to ABS system maintenance significantly extends component life and maintains optimal safety performance.

Regular Maintenance Practices:

Brake fluid management represents the most critical maintenance factor affecting ABS control module longevity. Change brake fluid every 2-3 years regardless of mileage, as brake fluid absorbs moisture over time that can damage both hydraulic and electronic components. Always use manufacturer-specified brake fluid type, as incorrect fluid can damage seals and affect system operation.

Monitor brake fluid level monthly by checking the reservoir when the vehicle is parked on level ground. Low fluid levels can indicate leaks or worn brake components that need attention. Check fluid color and consistency regularly – fresh brake fluid is typically clear or light amber, while contaminated fluid appears dark or contains visible particles.

Respond immediately to ABS warning lights, as early intervention can prevent minor problems from becoming major failures. Address any changes in brake performance promptly, including changes in pedal feel, unusual noises, or variations in stopping ability. Schedule regular comprehensive brake system inspections as part of your routine maintenance program.

Environmental Protection Strategies:

Moisture represents one of the greatest threats to ABS control module longevity. Keep the brake fluid reservoir tightly sealed to prevent moisture intrusion, and address any leaks immediately to prevent contamination of the system. When washing your vehicle, avoid directing high-pressure water at electrical connections or the ABS module area.

Protect electrical connections from road salt and corrosive chemicals by inspecting them regularly and applying appropriate protective treatments when necessary. In areas where road salt is common, consider more frequent brake fluid changes and additional system inspections during winter months.

Heat Management Considerations:

Excessive heat accelerates the aging of electronic components and can cause premature ABS control module failure. Avoid prolonged periods of hard braking that generate excessive heat in the brake system. When possible, use engine braking or downshifting to reduce reliance on the brake system during long downhill descents.

Allow adequate cooling time between periods of heavy brake use, particularly during mountain driving or towing operations. Monitor for signs of brake system overheating such as unusual odors, brake pedal changes, or warning light activation. Ensure proper cooling airflow to brake components by keeping brake vents and cooling passages clear of debris.

Optimal Driving Practices:

Your driving habits directly affect ABS system longevity and performance. Practice smooth, progressive braking whenever possible to reduce system stress and extend component life. Avoid unnecessary hard braking by maintaining appropriate following distances and anticipating traffic conditions.

Allow the ABS to function properly during emergencies by maintaining steady pressure on the brake pedal and avoiding the urge to pump the brakes. The system is designed to prevent wheel lockup more effectively than manual brake pumping. Don’t be alarmed by the normal pulsation and noise that occurs during ABS activation – this indicates the system is working properly.

Warning Sign Recognition:

Learn to recognize the normal sounds and sensations of ABS operation so you can identify abnormal conditions early. Normal ABS activation produces a rapid pulsation in the brake pedal and a grinding or chattering noise from the system. Abnormal conditions include random pulsation during normal braking, unusual noises when not braking, or changes in the intensity or frequency of normal ABS sounds.

Recognize early warning symptoms such as gradual increases in brake pedal effort, intermittent warning lights, or subtle changes in brake system behavior. These early signs often indicate developing problems that can be addressed before complete system failure occurs.

Don’t ignore intermittent problems, as they often indicate components that are beginning to fail. Address issues promptly to prevent cascade failures where one problem causes additional damage to related components.

Professional Service Intervals:

Schedule annual comprehensive brake system inspections that include ABS system evaluation. During regular vehicle service, request diagnostic scans to check for stored codes that might not yet trigger warning lights. These early fault codes can identify developing problems before they cause system failures.

Consider brake fluid analysis during major service intervals to check for contamination or moisture content that could damage system components. Professional fluid analysis can identify problems before they cause expensive component damage.

Have electrical connections and wiring inspected periodically, particularly in vehicles exposed to harsh conditions such as salt, extreme temperatures, or frequent water exposure. Professional inspection can identify corroded connections or damaged wiring before they cause system malfunctions.

When to Seek Professional Help:

Seek immediate professional service for any ABS warning light activation, regardless of how minor it might seem. Changes in brake pedal feel or response require professional evaluation, as do unusual noises during braking or vehicle pulling during brake application.

Any time you suspect brake system problems, prioritize safety over cost and have the system professionally evaluated. Brake system problems can develop quickly and without warning, making prompt professional attention essential for safety.

Establish a relationship with a qualified brake system specialist who understands your vehicle and can provide ongoing maintenance and service. Regular professional attention helps identify problems early and ensures optimal system performance throughout your vehicle’s life.

Safety Warnings and Professional Recommendations

The ABS control module is not just another automotive component – it’s a critical safety system that can mean the difference between life and death in emergency situations. Understanding when to stop driving, how to recognize dangerous conditions, and when to seek professional help is essential for your safety and the safety of others sharing the road with you.

Critical Safety Considerations:

Certain conditions require immediate action and professional intervention. If your brake pedal becomes completely unresponsive or goes to the floor without providing adequate stopping power, stop driving immediately and call for professional assistance. This represents a potential brake system emergency that could result in serious accidents if not addressed promptly.

Never ignore ABS warning lights, even if they seem intermittent or minor. These lights indicate that your anti-lock braking system has detected a problem and disabled itself for safety reasons. While your regular brakes may continue to function, you’ve lost the critical safety benefit that prevents wheel lockup during emergency braking situations.

Don’t attempt DIY repairs on safety-critical brake system components, regardless of your mechanical experience. ABS control modules require specialized diagnostic equipment, manufacturer-specific programming software, and professional expertise to service safely. Incorrect procedures can result in brake system failure, putting you and others at serious risk.

Dangerous Conditions Requiring Immediate Action:

Several conditions indicate immediate danger that requires stopping driving and seeking professional help. Complete brake pedal failure, where the pedal provides no resistance or stopping power, represents an emergency requiring immediate safe stopping using whatever means available, including the parking brake if necessary.

If your brake pedal travels to the floor without stopping the vehicle effectively, this indicates a serious hydraulic system problem that could result in complete brake failure. Unusual brake system noises or smells, particularly burning odors or grinding sounds when not intentionally braking, can indicate dangerous component failures.

Vehicle pulling severely to one side during braking suggests significant brake system problems that affect vehicle control and stopping ability. This condition can cause loss of control during emergency braking and requires immediate professional attention.

Emergency Procedures:

When brake problems occur while driving, your first priority is finding a safe location to stop. Reduce speed gradually using engine braking, downshifting, or carefully applying the parking brake. Avoid sudden steering inputs that could cause loss of control, and use hazard lights to warn other drivers of your situation.

If you must use the parking brake to stop, apply it gradually to avoid locking the rear wheels and causing a skid. Once safely stopped, call for professional towing service rather than attempting to drive to a repair facility. The risk of brake failure during continued driving far outweighs the inconvenience and cost of towing.

Keep emergency contact information readily available, including qualified towing services and brake system specialists. Program these numbers into your phone and keep written copies in your vehicle for situations where your phone might not be available.

Choosing Qualified Service Providers:

Not all automotive service providers are equally qualified to service ABS systems. Look for ASE-certified brake system technicians who have specific training and experience with anti-lock braking systems. These professionals possess the knowledge and skills necessary to safely diagnose and repair complex ABS problems.

Verify that the service facility has access to manufacturer diagnostic equipment and software necessary for proper ABS service. Generic diagnostic tools may not provide the comprehensive information needed for accurate diagnosis and repair of modern ABS systems. Manufacturer-specific equipment ensures accurate diagnosis and proper programming of replacement modules.

Choose service providers with experience working on your specific vehicle make and model, as ABS systems vary significantly between manufacturers. What works for one brand may not apply to another, and experienced technicians understand these differences and can avoid costly mistakes.

Ensure the service facility carries proper insurance coverage and provides comprehensive warranty protection for their work. ABS system repairs represent significant investments, and warranty coverage protects you against defective parts or improper installation that could compromise safety.

Professional Facility Requirements:

Quality ABS service requires more than just basic automotive repair capabilities. The facility should offer complete brake system service capabilities, including hydraulic system repair, electronic diagnostics, and component replacement. Partial service capabilities may result in incomplete repairs or overlooked problems.

Access to manufacturer software for programming replacement modules is essential, as most modern ABS control modules require extensive programming after installation. Facilities without this capability cannot complete ABS module replacement properly, leaving you with non-functional safety systems.

Proper tools for hydraulic system service ensure that brake bleeding and pressure testing are performed correctly. Specialized ABS bleeding procedures require equipment that many basic service facilities don’t possess, making comprehensive service capability essential.

Quality parts sourcing and warranty support protect your investment and ensure long-term reliability. Reputable service providers use quality replacement parts and stand behind their work with comprehensive warranty coverage.

Final Safety Recommendations:

Always prioritize safety over cost savings when dealing with brake system problems. The potential consequences of brake system failure far outweigh any savings from choosing inferior service or delaying necessary repairs. Your life and the lives of others depend on your brake system functioning properly.

Use only qualified professionals for all brake system work, regardless of the complexity or apparent simplicity of the problem. Even seemingly minor brake issues can indicate serious underlying problems that require professional expertise to identify and correct safely.

Maintain complete service records for all brake system work, including ABS service and repairs. These records help service providers understand your vehicle’s history and can be essential for warranty claims or diagnosing recurring problems.

Address brake system problems promptly to prevent escalation into more serious and expensive conditions. Early intervention often prevents minor problems from becoming major failures that compromise safety and require extensive repairs.

Long-term Safety Strategy:

Establish a relationship with a trusted brake system specialist who understands your vehicle and driving conditions. Regular professional attention helps identify problems early and ensures optimal system performance throughout your vehicle’s operational life.

Follow manufacturer maintenance schedules for brake system service, including ABS components. These schedules are designed to prevent problems and maintain optimal safety performance based on extensive testing and real-world experience.

Keep emergency contact information readily available, including qualified towing services and brake system specialists. In emergency situations, having immediate access to professional help can prevent accidents and ensure your safety.

Consider extended warranty coverage for older vehicles, particularly those with complex integrated ABS systems. Extended warranties can provide valuable protection against expensive ABS control module failures and ensure access to quality repair services.

Remember that ABS systems are designed to enhance safety, not replace safe driving practices. Maintain appropriate following distances, drive according to conditions, and always be prepared for emergency situations. The best safety system is a well-maintained vehicle operated by a conscientious driver who understands both the capabilities and limitations of their vehicle’s safety systems.

For comprehensive information about brake system maintenance and repair, explore our complete Vehicle Systems & Parts Explained resource library, where you’ll find detailed guides covering all aspects of vehicle safety systems and maintenance procedures.

Disclaimer: This information is provided for educational purposes only. Always consult qualified professionals for diagnosis and repair of brake system problems. Repairs Advisor provides technical manuals and information but does not perform direct repair services. For immediate assistance with brake system problems, contact qualified automotive professionals in your area.